- sales@alummc.com

- Xin'an Industrial Assemble Region,Luoyang,Henan Province,China

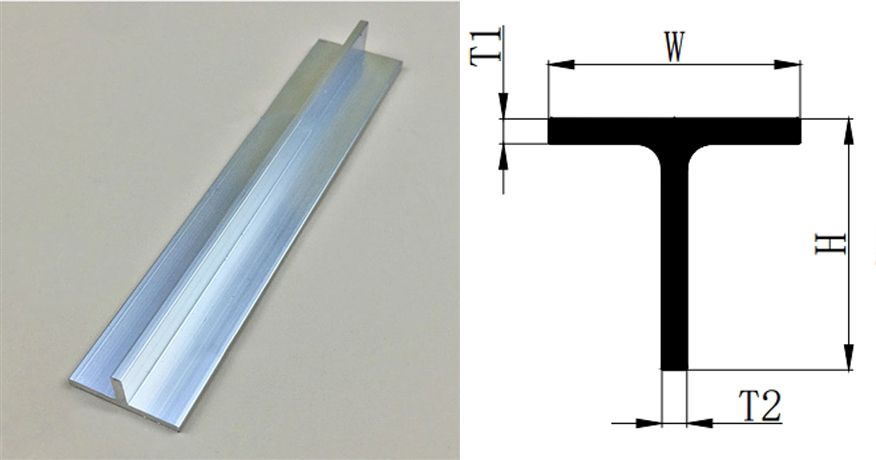

T-type aluminum is an aluminum profile with a "T"-shaped cross section, consisting of a vertical web and two horizontal flanges, and its shape is similar to the cross section of a tie rod.

Marine T-type aluminum usually uses specific aluminum alloy grades, such as 5083, 5086 or 6061.

Marine T-type aluminum can be connected by a variety of welding methods, such as TIG welding, MIG welding, laser welding, etc.

MC Aluminum can customize various specifications of 5 series aluminum plates, 6 series patterned plates and angle aluminum, aluminum tubes, square tubes, T profiles,I-type aluminum, flat aluminum, ball head aluminum and other marine aluminum profiles for customers.

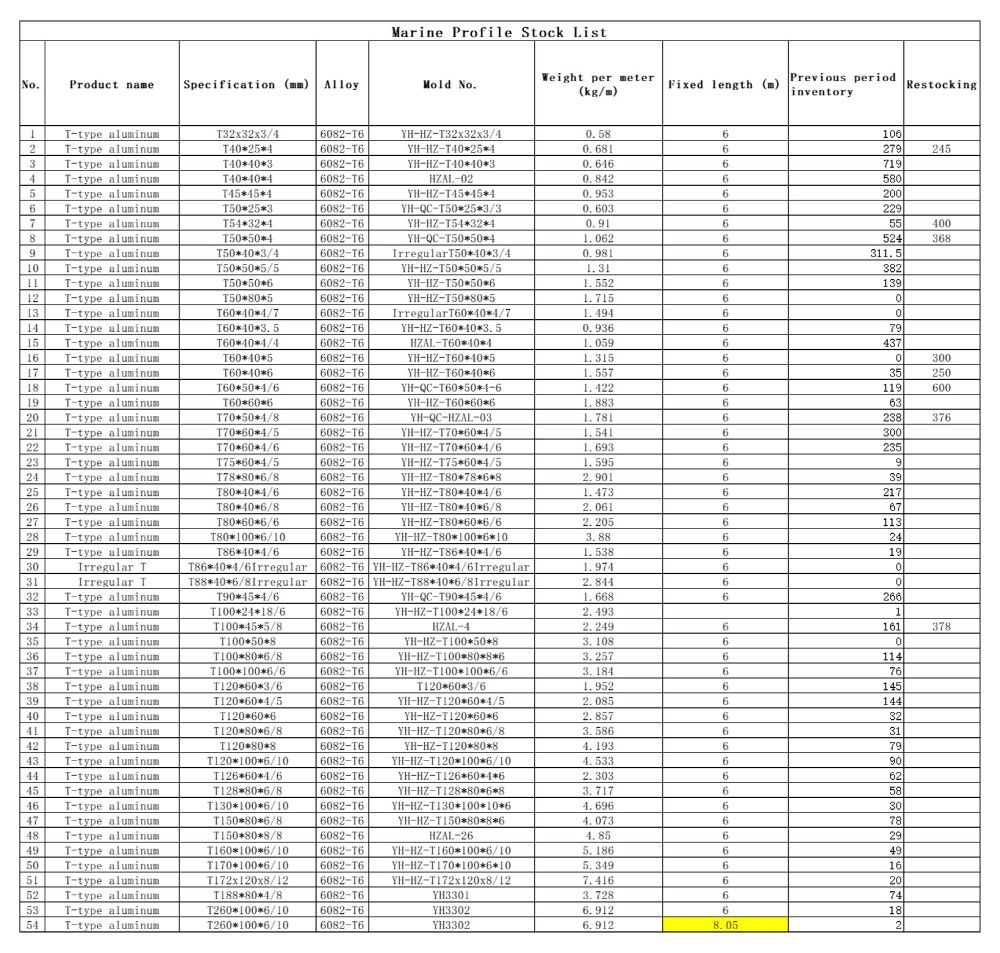

T-type aluminum specifications:

| T-type aluminum | |||

H (mm) | W (mm | T1 (mm) | T2 (mm) |

| 40 | 40 | 4 | 4 |

| 50 | 50 | 4 | 4 |

| 50 | 60 | 6 | 4 |

| 60 | 70 | 5 | 4 |

| 45 | 90 | 6 | 4 |

| 80 | 100 | 8 | 6 |

| 50 | 120 | 6.5 | 6.5 |

| 80 | 120 | 8 | 6 |

| 50 | 140 | 7.5 | 7.5 |

| 80 | 150 | 8 | 8 |

Marine aluminum T profile specifications:

| Alloy | 5083, 5086, 5383, 5059, 6061, 6082, 6005A |

| Temper | H111/H112, T5/T6 |

| Certification | BV /DNV /ABS,etc |

| Thickness | 3-50mm |

| Marine Aluminum T Bar Aluminum Alloys Composition | |||||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Ga | Other | Al | |

| Each | Total | ||||||||||||

| 5083 | 0.40 | 0.40 | 0.1 | 0.4-1.0 | 40.-4.9 | 0.05-0.25 | - | 0.25 | 0.15 | - | 0.05 | 0.15 | Remainder |

| 5383 | 0.25 | 0.25 | 0.20 | 0.7-1.0 | 4.0-5.2 | 0.25 | - | 0.40 | 0.15 | - | 0.05 | 0.15 | Remainder |

| 5086 | 0.40 | 0.50 | 0.1 | 0.2-0.7 | 3.5-4.5 | 0.05-0.25 | - | 0.25 | 0.15 | - | 0.05 | 0.15 | Remainder |

| 5059 | 0.45 | 0.05 | 0.25 | 0.6-1.2 | 5.0-6.0 | 0.25 | - | 0.4-0.9 | 0.20 | - | 0.05 | 0.15 | Remainder |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | - | 0.25 | 0.15 | - | 0.05 | 0.15 | Remainder |

| 6005A | 0.5-0.9 | 0.35 | 0.3 | 0.5 | 0.4-0.7 | 0.3 | - | 0.2 | 0.1 | - | 0.05 | 0.15 | Remainder |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.4-1.0 | 0.6-1.2 | 0.25 | - | 0.2 | 0.1 | - | 0.05 | 0.15 | Remainder |

| Mechanical Properties of Marine Aluminum T Bar | |||||||

Alloy | Form | Thickness(mm) | Temper | Rm | Rp0.2 | A% Min | |

Min. | Aso | Aso | |||||

5086 | Shapes, Bar, Tube | 3≤t≤50 | H112 | 240 | 95 | 10 | 12 |

| 5083 | Shapes, Bar, Tube Shapes, Bar, Tube | 3≤t≤50 | H111 | 270 270 | 110 125 | 10 10 | 12 12 |

| 5059 | Shapes, Bar, Tube | 3≤t≤50 | H112 | 330 | 200 | 10 | |

5383 | Shapes, Bar, Tub | 3≤t≤50 | O | 290 | 145 | 17 | 17 |

Shapes, Bar, Tub | 3≤t≤50 | H112 | 310 | 190 | 13 | ||

6061 | Shapes, Bar, Tube Profiles | 3≤t≤50 3≤t≤50 | T5 or T6 | 260 245 | 240 205 | 10 | 8 4 |

| 6005A | Shapes, Bar, Tube Profiles | 3≤t≤50 | T5 | 260 | 215 | 9 | 8 |

Shapes, Bar, Tube Profiles | 3≤t≤10 | T6 | 260 | 215 | 8 | 6 | |

3≤t≤10 | 250 | 200 | 8 | 6 | |||

6082 | Shapes, Bar, Tube Closed shapes | 3≤t≤50 3≤t≤50 | T5 or T6 | 310 290 | 260 240 | 10 | 8 5 |

Summary of T-type aluminum features:

1. High strength: After reasonable design and processing, it has high strength and rigidity and can withstand loads.

2. Corrosion resistance: Aluminum has good corrosion resistance and is suitable for a variety of environments.

3. Lightweight: Compared with other metals, aluminum is lighter and suitable for occasions where weight reduction is required.

4. Easy to process: It is easy to cut, drill, bend and other processes, suitable for installation and modification.

5. Structural stability: The T-type structural design of T-type aluminum provides excellent bending and torsion resistance, suitable for hull structural parts that require stability and load-bearing capacity.

Application areas of marine T-type aluminum:

1. Hull structure: used to manufacture hull frames, beams and longitudinal beams to provide support and stability.

2. Deck and platform: can be used for laying and reinforcement to improve load-bearing capacity and safety.

3. Cabin separation and decoration: used to make partitions, handrails, door and window frames to improve living comfort and aesthetics.

Q1: What is the production time for new molds and mass production?

A1: It takes 7-15 days to make a new mold.

Mass production: about 20-35 days after getting 30% deposit.

Q2: What certifications do you have?

A2: Provide ISO9001 quality management system certification.

Get CCS, BV, LR, DNV-GL approval for welding process and products.

Q3: What is your minimum order quantity?

A3: Generally 1-3 tons.

Q4: How do you charge mold fees?

A4: It is free to use our existing molds, but for custom aluminum profiles, the mold fee will be returned to customers when your order quantity reaches a certain amount.

Q5: Which countries are sold?

A5: Exported to more than forty countries and regions including Australia, South Korea, Saudi Arabia, Mexico, Japan, Singapore, Pakistan, etc.

Q6: What are the payment terms?

A6: 30% TT for deposit, 70% TT /70% LC at sight balance before shipment

Q7: What is the packaging method?

A7: Normally we use plastic film and kraft paper, but we can also make it according to customers' requirements.