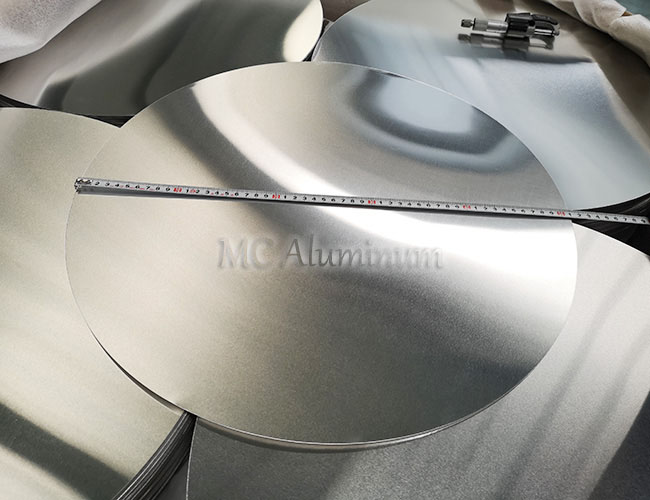

3003 Cold Rolled Aluminum Circles for Tableware

The tableware industry demands materials that are lightweight, corrosion-resistant, environmentally friendly, non-toxic, and highly formable.

3003 cold rolled aluminum circles are the ideal material to meet these strict requirements.

Cookware aluminum circles are produced from premium 3003 aluminum alloy, primarily composed of aluminum and manganese, with manganese content ranging from 1.0% to 1.5%. Processed through a cold rolling technique, the material offers excellent ductility, workability, corrosion resistance, and uniform surface flatness, making it highly suitable for manufacturing tableware, pots, and kitchen utensils.

Compared to pure aluminum grades such as 1060 or 1100, the strength of 3003 aluminum circles is about 10% higher, allowing cookware and tableware to maintain better shape stability during forming and use.

Depending on application requirements, 3003 aluminum circles can be supplied in various tempers such as O (soft), H14, and H18. The O-temper has the highest ductility, making it ideal for deep drawing or heavy forming processes.

Why Choose 3003 Aluminum Circles?

1. Corrosion and Oxidation Resistance

The 3003 aluminum alloy naturally forms a dense oxide film on its surface, effectively preventing oxidation, corrosion, and discoloration. This ensures that tableware maintains its shine even after long-term use.

2. Excellent Formability

Cold rolled 3003 aluminum circles exhibit high ductility and deep-drawing properties, making them perfect for producing bowls, plates, spoons, and pans. Even during complex drawing and spinning processes, the surface remains smooth and free of cracks.

3. Lightweight Design

Compared with traditional stainless steel cookware, aluminum tableware is lightweight yet durable, making it easier to handle, carry, and use, while maintaining the necessary strength.

4. Environmentally Friendly and Food-Safe

3003 aluminum circles comply with international food-grade standards, containing no harmful metals and being safe for direct food contact.

5. Multiple Surface Finishing Options

The smooth surface of cold rolled aluminum circles allows for anodizing, coating, or brushing treatments, which not only enhance durability but also improve aesthetic appearance.

6. Excellent Thermal Conductivity

3003 aluminum circles maintain outstanding heat transfer efficiency, ensuring cookware heats quickly and evenly, shortening cooking time, saving energy, and preventing localized burning of food.

Applications of 3003 Aluminum Circles

Household Tableware: bowls, plates, cups, spoons

Kitchen Cookware: stockpots, frying pans, steamers

Hotel and Catering Utensils: serving trays, dishes, condiment plates

Portable Outdoor Tableware: foldable aluminum plates, lunch boxes

Differences Between Cold Rolled and Hot Rolled 3003 Aluminum Circles

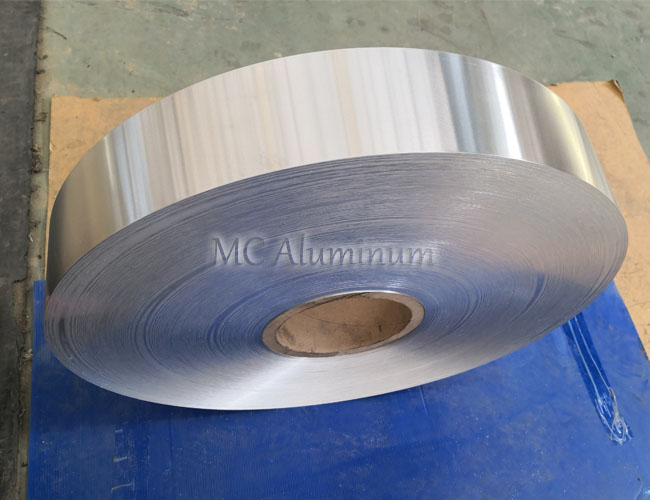

It is important to note that 3003 aluminum discs can be produced using cold rolling or hot rolling, and each process results in distinct material characteristics.

Cold Rolled

Processed below the recrystallization temperature, cold rolled aluminum circles offer superior surface finish and dimensional accuracy. However, when anodized, cold rolled products may exhibit color variations or minor surface stains.

Hot Rolled

Processed above the recrystallization temperature, hot rolled aluminum circles provide better formability. For cookware or tableware that requires anodizing treatment (for improved wear resistance and appearance), hot rolled products are generally recommended.

Contact Us