3003 Non-Stick Cookware Aluminum Discs

In modern kitchens, non-stick cookware is one of the most popular kitchen utensils. Its lightweight, fast heating, and easy-to-clean features make it the preferred choice for home cooking. In the manufacturing of non-stick pans, 3003 aluminum circles play a vital role. They not only serve as the main material of the pan body but also determine the performance, durability, and cost-effectiveness of the cookware.

3003 aluminum alloy belongs to the Al-Mn series (3xxx series) and is a typical rust-resistant aluminum. Its strength is slightly higher than 1000 series pure aluminum circles. It is produced using hot rolling or cold rolling processes, with hot-rolled products offering uniform internal structure and better plasticity, suitable for deep drawing and spinning processes.

3003 aluminum circle discs are usually produced in O, H14, H24 temper to ensure they do not crack during subsequent stamping or spinning processes.

For non-stick cookware applications, the disc surface undergoes anodizing, sandblasting, or coating treatments, creating a solid foundation for the non-stick layer and improving adhesion.

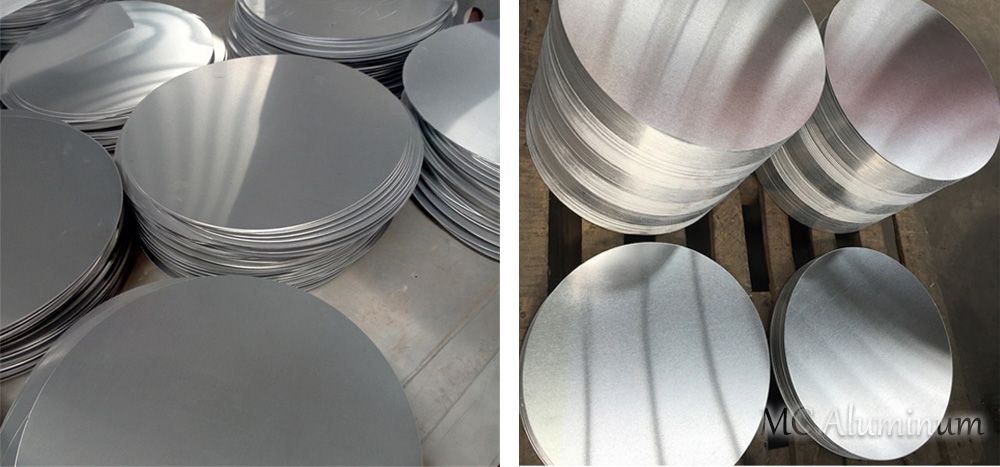

MC Aluminum, as a professional aluminum disc manufacturer, uses CNC punching or spinning equipment to process aluminum plates into standard-sized discs. Diameters generally range from 100mm to 1200mm, and thicknesses from 0.4mm to 6mm, which can be customized according to different cookware specifications.

Performance Advantages of 3003 Aluminum Wafers

1. Excellent Thermal Conductivity: 3003 aluminum conducts heat efficiently, allowing the pan to heat evenly and avoid hot spots.

2. Moderate Strength: Stronger than 1000 series, suitable for pan bottoms and spinning-forming parts, ensuring a longer service life.

3. Good Deep Drawing & Spinning Performance: High ductility, less prone to cracks during processing, suitable for complex pan shapes.

4. Corrosion Resistance: Resists moisture and acidic or alkaline foods in kitchens, preventing rust.

5. Compatibility with Various Coatings: The surface easily accommodates anodizing, sandblasting, and non-stick coatings, enhancing adhesion and durability.

6. High Cost-Effectiveness: More affordable than 5xxx or 7xxx series, suitable for mass production of cookware.

Specifications of 3003 Aluminum Discs

| Alloy | 3003 |

| Temper | O, H12, H14, H24 |

| Thickness | 0.4 mm - 6.0 mm |

| Diameter | 100 mm - 1200 mm |

| Production Process | CC / DC |

| Surface | Bright, matte, sandblasted, anodized, etc. |

| Tolerance | ±0.01mm (customizable) |

| Sample | 1-3 pcs |

| MOQ | 1-3 tons |

Applications of 3003 Cookware Aluminum Discs

Non-stick frying pans

Milk pots and soup pots

Pressure cooker and steamer bases

Induction cooker composite bottom discs

Industrial cookware for hotels and catering

Surface Treatment Options for 3003 Aluminum Discs

Depending on the quality requirements of the final product, 3003 aluminum discs can be treated in different ways:

Anodizing: Creates a porous oxide layer to enhance coating adhesion.

Single-Side Coating & Single-Side Anodizing: Common for rice cooker inner pots.

Double-Side Coating: Suitable when both sides require protective layers.

Hard Anodizing: Creates a harder, wear-resistant surface for high-demand cookware.

Comparison with Other Aluminum Circles

Besides 3003 aluminum discs, cookware manufacturing also uses 1050, 1060, 1070, and 1100 pure aluminum series.

3003 discs: Contain manganese, higher strength, excellent formability, corrosion resistance, and weldability. Ideal for non-stick pans.

1050/1060/1070 discs: Pure aluminum, good formability, but lower strength than 3003; suitable for standard cookware.

1100 discs: Lower strength than 3003, slightly less corrosion-resistant.

Contact Us