3004 Aluminum foil is suitable for lunch box materials, container foil, and aluminum honeycomb core

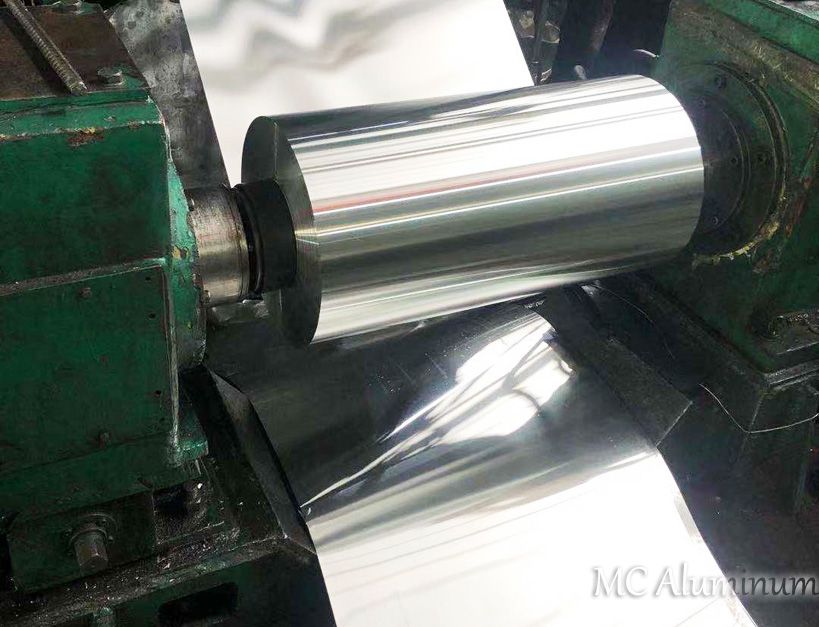

As an aluminum foil manufacturer with rich production experience, MC Aluminum produces 3004 aluminum foil with high hardness, good load-bearing, and better stamping effect than 3003 aluminum foil. It can be used in aluminum foil lunch boxes and the product is hygienic. 3004 aluminum foil products have good shape, no black wires, no bright lines, no holes, multiple advantages, high quality and low price.

1. Lunch box materials

3004 aluminum foil has significant advantages as a lunch box material. First of all, its high hardness and good load-bearing make the lunch box more stable when loading food. Secondly, the stamping effect of 3004 aluminum foil is better than that of 3003 aluminum foil, and it can be processed into various shapes to meet the design needs of different lunch boxes. In addition, the 3004 aluminum foil lunch box has a clean appearance and good thermal conductivity. It can be heated directly on ovens, microwave ovens, steamers and other kitchenware, making it easy to use, safe and hygienic. At the same time, aluminum resources can be recycled and reused, which is in line with the concept of environmental protection.

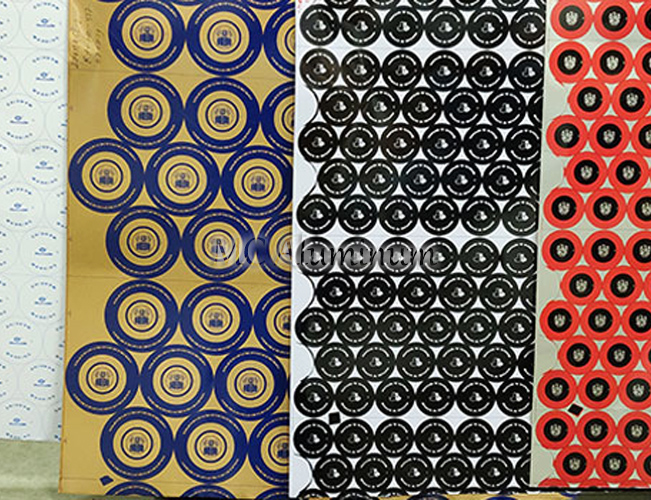

2. Container foil

In the field of container foil, 3004 aluminum foil also performs well. Its good sealing performance and light-shielding properties can effectively protect the freshness and safety of items in the container and avoid the growth of microorganisms. In addition, 3004 aluminum foil has good shape, clean oil removal and few holes, making the container more stable and reliable during processing and use. These characteristics make 3004 aluminum foil an ideal material for making various containers, such as food packaging containers, pharmaceutical packaging containers, etc.

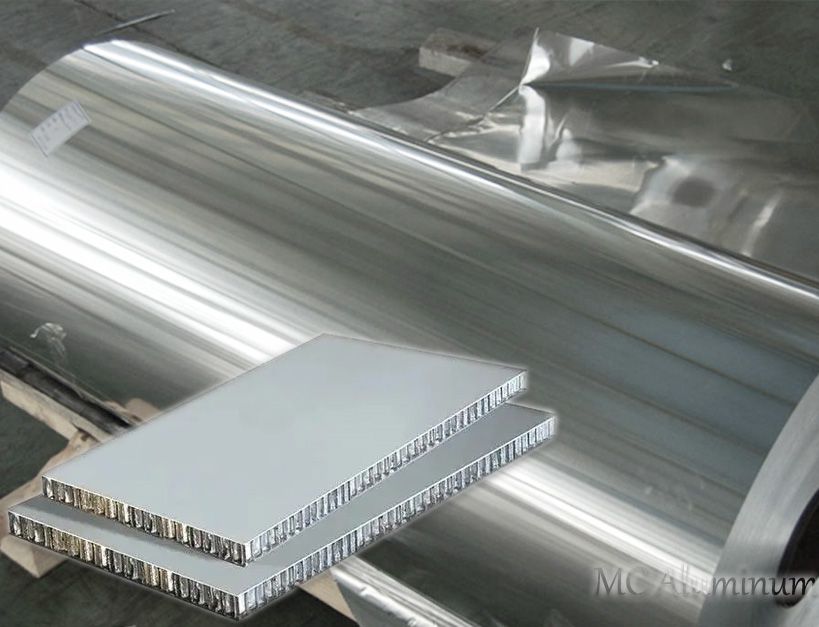

3. Aluminum honeycomb core

Aluminum honeycomb core is a composite material made of multiple layers of aluminum foil bonded together. It has the advantages of light weight, impact resistance, high stiffness, good flatness, sound insulation and heat insulation. 3004 aluminum foil is an ideal material for making aluminum honeycomb cores. Its high strength and excellent processing properties enable the aluminum honeycomb core to maintain a stable structure even when it bears greater strength. In addition, the surface of 3004 aluminum foil is degreased and clean, and the adhesive is not easy to fall off, further improving the reliability and durability of the aluminum honeycomb core. Therefore, 3004 aluminum foil is also widely used in the field of aluminum honeycomb core, such as building curtain walls, interior decoration, honeycomb panels for motorcycles, honeycomb cores for ships, etc.

MC Aluminum aluminum foil manufacturer supplies aluminum foil products with a thickness of 0.02-0.2mm. The aluminum foil product series includes 1/3/5/8 series, which are widely used in bottle cap materials, pharmaceutical packaging, aluminum foil tape, lunch box materials, food packaging, and electronic products. , honeycomb core, etc. The company undertakes aluminum foil orders of 3-2000 tons, factory direct sales, and exported to many overseas countries.

Contact Us