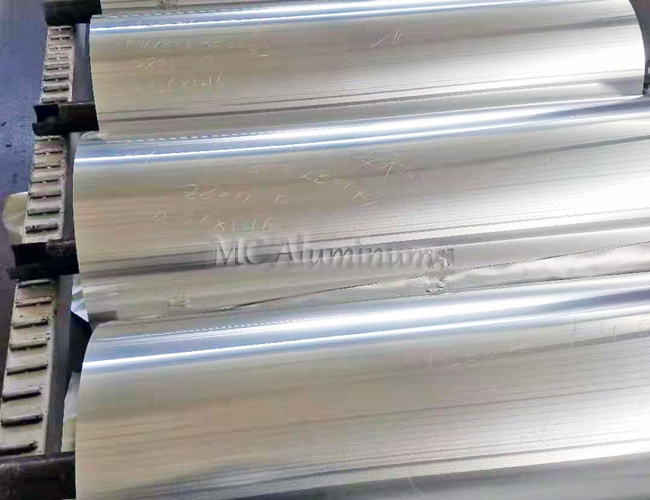

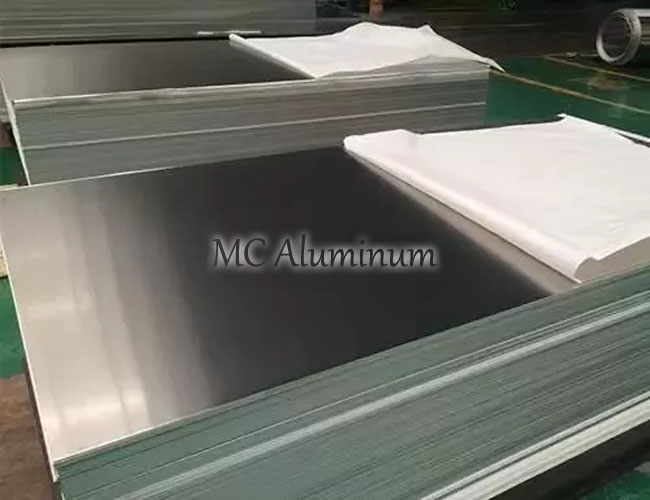

4343 3003 4343 Aluminium Clad Strip for automobile radiator

In the automobile manufacturing industry, high-performance and high-efficiency heat dissipation systems are essential for the long-term stable operation of vehicles, and new radiator composite materials are leading the revolution. Traditional radiators mainly use metal materials, but new materials combine the thermal conductivity of metals with the lightweight and corrosion-resistant properties of composite materials, becoming the new favorite of the automotive industry, improving vehicle performance while promoting environmental protection and energy saving.

The key components of the automotive heat exchange system include condensers, evaporators, radiators, intercoolers, heaters and oil coolers. The core material of the automotive heat exchanger is brazed composite aluminum sheet and foil. Its process technology features are the use of rolling composite technology, coating one or both sides of the 3xxx series aluminum matrix (core layer) with 4xxx series brazing materials, and rolling them together on a hot rolling mill under high temperature and high pressure welding, and then cold rolling to the finished product.

Introduction to brazed composite aluminum sheet and strip alloys:

4343 Aluminum alloy: mainly used for cladding materials. It contains high silicon and provides good corrosion resistance and weldability. Usually used for the inner and outer layers of composite strips.

3003 Aluminum alloy: Mainly used for core material. It is an aluminum-manganese alloy with excellent corrosion resistance and formability, and excellent thermal conductivity.

Aluminum composite strip for automobile radiator 4343 3003 4343 Specifications:

| Clad Aluminium Sheet/Strip for Heat Transfer | ||

| Material Alloy | Core Material | 3003, 3003+1%Zn, 3003+1.5%Zn, 3003+1.5%Zn+Zr, 3003+0.5%Cu, 3005, etc |

| Cladding Material | 4343, 4343+1%Zn, 4045, 4045+1%Zn, 4004, 7072, 5005, etc | |

| Clad Level | 4~18% (±1.5%) | |

| Temper | O, H14, H16, H18, H22, H24 , etc | |

| Size | As following specs sheet, or made on request | |

| Type | Sheet, Coil, Strip | |

| Thickness | 0.2--8.0mm | |

| Width | 30--2200mm | |

| Length | 400--12000mm | |

| Tensile Strength | 95Mpa~235Mpa (Depending on temper) | |

| Yield Strength | 35Mpa~160Mpa (Depending on temper) | |

| Elongation | 1%~15% (Depending on temper) | |

| Main Application | Heat exchanger, auto radiator, charge air cooler, evaporator, condenser,aluminium fin, header plate, HF welded pipe/tube, etc | |

| MOQ | 1-3 tons | |

Advantages of aluminum radiator composite materials:

1. Low density, lightweight, reducing the weight of the car and improving fuel economy.

2. Corrosion resistance, extended service life

3. High thermal conductivity

4. Excellent strength and rigidity

5. Easy to weld, good processing performance

MC Aluminum is a large aluminum sheet manufacturer, an aluminum processing enterprise integrating R&D, processing and manufacturing, with more than 20 years of production experience, advanced technology and equipment, and sophisticated production technology. MC Aluminum currently supplies 4343/3003, 3003mod/4343, 3003mod, 3003mod/4045, 3003/4045, 4343/3003/4343 and other aluminum alloy composite plates for heat exchangers, which have been verified by mainstream manufacturers, with stable product quality, exported overseas, and factory direct sales.

Contact Us