Air plane lunch box aluminum foil

With the improvement of people's living standards, whether it is work, study or play, people will choose a faster way to travel, which also drives the development of aviation industry. When flying, the staff on the plane will provide food for passengers. Generally, Aluminum foil lunch boxes will be used.

As a safe, hygienic and environmentally-friendly material, aluminum foil, as a packaging material, is characterized by its excellent barrier performance, which can effectively block air, water and light, thus maintaining or extending the shelf life and freshness of food. Aviation aluminum foil box is generally made of 8011, 5052 or 8006 alloy aluminum foil through punching and one-time stamping with a die. It is sanitary, resistant to high and low temperatures, green and environment-friendly, renewable and energy-saving, good in sealing, high-grade and beautiful, convenient and quick, etc.

Aviation aluminum foil lunch boxes can be divided into two types in terms of appearance and quality: one is a wrinkled lunch box directly punched from light foil, and its thickness is generally 0.06~0.07mm, which is cost-effective; the other is a coating Aluminum foil lunch box, the thickness is generally 0.08~0.09mm. The coating material is food-grade resin coating, and the transparent or white coating is attached to the aluminum foil through high temperature coating, so that the aluminum foil is isolated from the air and avoids oxidation and blackening of the aluminum foil. Therefore, most airlines use this coated aluminum foil box to provide meals to passengers.

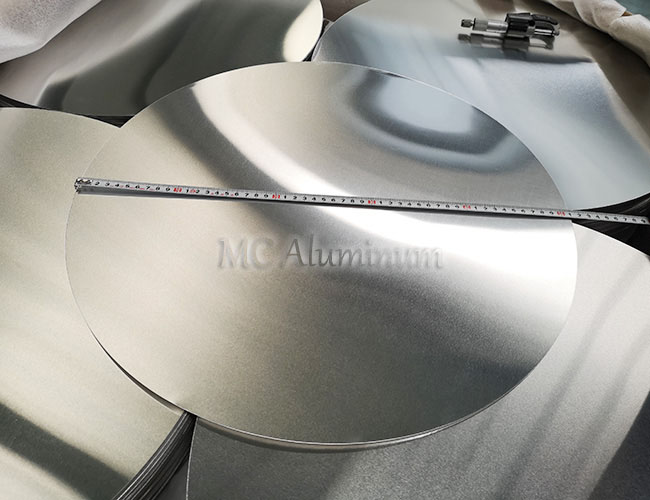

MC Aluminum has complete product specifications and huge production capacity, specializing in the production of various specifications of aluminum sheets, aluminum coils, aluminum circles and other aluminum products, which can meet your individual processing needs and provide you with the latest product quotations. Looking forward to your consultation!

Contact Us