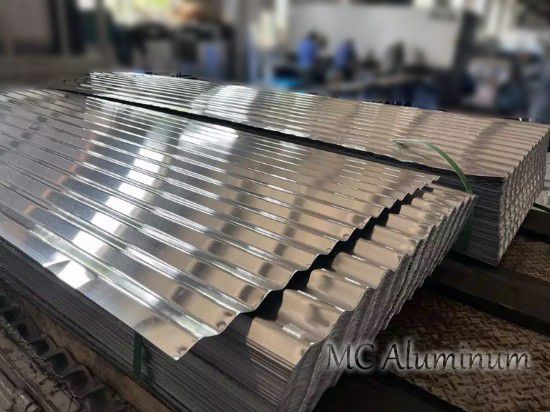

Aluminum alloy corrugated sheet

Corrugated aluminum sheets are rolled from aluminum-magnesium-manganese alloy sheets. They form various corrugated shapes after rolling and cold forming. Their cross-sections are wavy. They are suitable for industrial, civil buildings, warehouses and interior and exterior wall decoration. . It has the characteristics of light weight, high strength, fire resistance, long service life, and has been widely used.

Corrugated aluminum sheet specifications:

| Alloy | 1050, 1060, 1100, 3003, 5005, 5052, 5083, 3105, 3005 |

| Temper | O, H12, H14, H16, H18, H22, H24, H26 |

| Thickness | 0.5-3mm |

| Width | 300-1600mm |

| Length | 500-16000mm |

| Shape | Compass pattern / two columns / three columns / five columns, torn paper strips, orange peel, wood embossed, stucco embossed, hemisphere. |

Advantages of aluminum alloy corrugated sheets:

1. High strength and light weight

2. Strong corrosion resistance

3. Good sound insulation and heat insulation properties

4. Good fire resistance

5. Beautiful and usable

5. Quick and easy installation

6. Long service life, can be used for more than 20 years

Corrugated aluminum sheet applications:

Widely used in industry, hardware, cooling, decoration, packaging, air conditioning, disinfection cabinets, transformers, road signs, signs, printing, building curtain walls: halls, shops, balcony decoration: tunnel wall decoration, furniture, interior decoration, ceilings, bars; Billboards, exhibition platforms. ORM; automobile body, yacht, machinery decorative panel and other industries.

Contact Us