Aluminum alloy for two-piece cans

A two-piece can refers to a metal container consisting of two parts: a lid (top) and an integral, seamless can body with a bottom. The body of this type of metal container is drawn into a set shape. The forming method of this cup-shaped container is stamping processing, so the two-piece can is also often called a stamped can. Usually made of aluminum alloy. Aluminum cans are widely used as food containers because they are lightweight, seal well, conduct heat, and are easy to recycle.

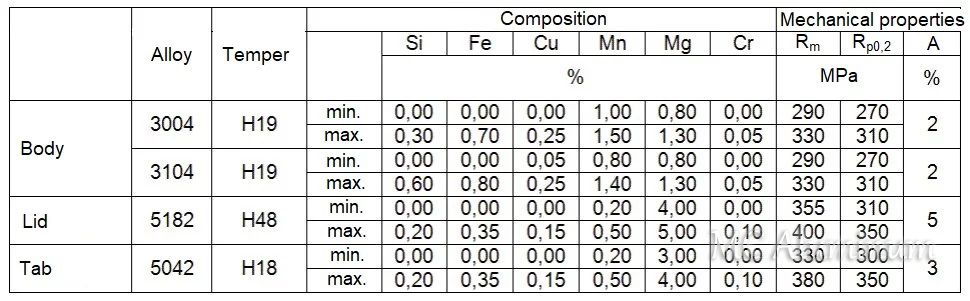

The aluminum can body is made of 3004 aluminum alloy strip or 3104 aluminum alloy strip, both of which are in H19 status. The cover is made of H48 condition 5182 aluminum alloy strip. For the pull tab, use H18 condition 5052 aluminum alloy strip. Aluminum cans are widely used in food packaging, medical packaging, chemical industry, electronics industry and other industries

Chemical composition

The advantages of aluminum cans over steel (tinplate) cans include:

1. High gas barrier, light-shielding and sealing properties

2. Light weight, low cost, competitive cost

3. Use easy-open aluminum ends: no can opener required

4.Good corrosion resistance

5. Easy to press and form, beautiful appearance. The can body has no seams and beautiful appearance, and the can body can be continuously decorated and printed with good effect.

6. High strength to prevent deformation caused during transportation and storage

As a professional aluminum sheet manufacturer, MC Aluminum specializes in the production of aluminum alloy strips for aluminum cans. It has a complete range of product models, excellent quality, low cost, and fast delivery. It is a trustworthy manufacturer of choice.

Contact Us