Aluminum circle production line technology

Aluminum is an important material often used in many industrial fields, so the market demand for aluminum wafers has also increased. In order to meet market demand, high-quality and reliable aluminum wafer manufacturers must improve and change their production line technology. Therefore, the production line technology of aluminum wafer manufacturers that is widely used now has the following characteristics.

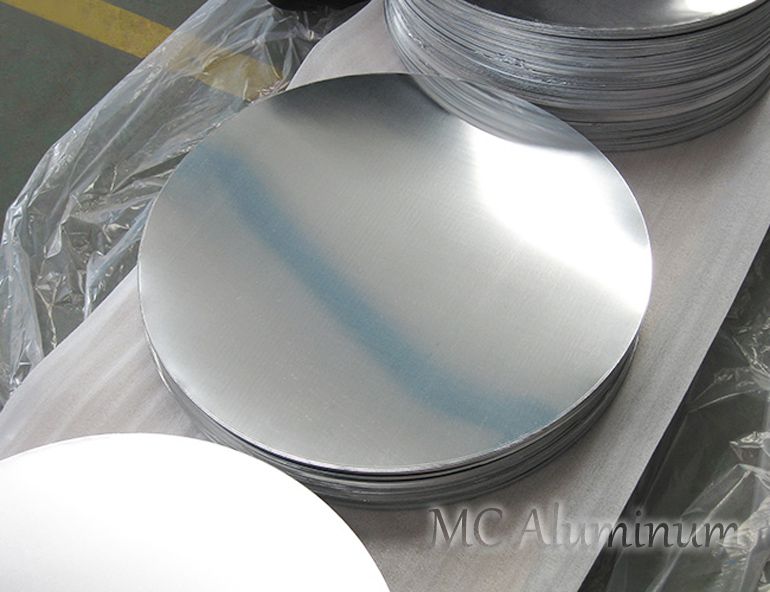

Aluminum circles are widely used in electronics, daily chemicals, medicine, culture, education and auto parts. Electrical appliances, insulation, machinery manufacturing, automobiles, aerospace, military industry, molds, construction, printing and other industries. Kitchenware supplies such as non-stick pans, pressure cookers, etc., and hardware supplies such as lampshades, water heater casings, etc. are among the deep-processed products of aluminum alloy plates and strips that are used in large quantities.

MC Aluminum aluminum wafer production line technology:

1. CNC is fully automatic. The production line starts from the unwinding of the coil until the entire coil of material is blanked. There is no need for manual contact with any work materials or any adjustments. This fundamentally eliminates the production safety hazards and product quality of ordinary punch punching. Hidden danger.

2. This line can use coil materials to directly produce wafers, without the need for slitting and cross-cutting of the coil materials, reducing the production process, reducing the production cost, reducing the possibility of damaging the surface of the coil materials, and producing The circles are guaranteed to be free of oil and scratches.

3. Make full use of the width of the roll material and adopt high-precision servo motor drive system control to reduce the distance between the wafers and the distance between the wafers and the material edge to a minimum, fundamentally reducing the amount of waste and making the raw material utilization rate reach more than 80%. .

4. The production speed can reach 40-55 pieces per minute, which improves production efficiency.

5. Due to the modular mold design, when changing wafer production specifications, the changeover time can be reduced to less than 15 minutes. The diameter range of wafers that can be produced ranges from 85mm to 750mm.

6. Advanced uncoiling system, six-layer leveling machine, high-rigidity mechanical press, automatic palletizing system, etc. ensure the high quality of wafer products.

MC Aluminum is a professional manufacturer of aluminum wafers, supplying 1,3,5,8 series aluminum wafers. The products have a smooth shape, no oil stains on the surface, and no burrs. They are exported to many overseas countries and regions. Direct sales from the manufacturer at the lowest price. discount.

Contact Us