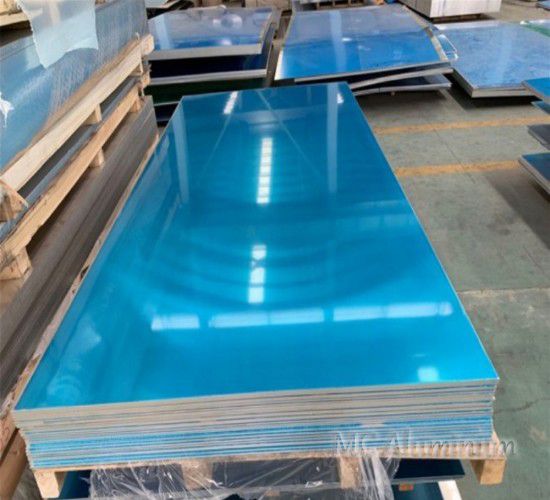

Blue PVC/PE film aluminum sheet roll

Aluminum sheet film refers to affixing a layer of PE protective film on the surface of the aluminum sheet to protect the surface of the aluminum sheet, which can effectively prevent the surface from being scratched, polluted, oxidized and corroded. It can be divided into two types: applying film on the aluminum coil and then cutting it, and subsequent secondary film application on the sheet.

According to the location of the film, it can be divided into front single-sided film and front double-sided film. Usually done in one go. Use a PE protective film with a thickness of 0.04-0.05mm and stick it on the aluminum sheet. According to the concentration of glue on the surface of aluminum sheet protective film, it can be divided into low-viscosity, medium-viscosity and high-viscosity protective films. The electrostatic protective film does not leave glue residue, but it is easy to fall off during machining.

Coated aluminum sheet specifications:

| Alloy | 1060 2024 3003 5052 6061 7075 8011 etc |

| Temper | temper H, temper O, temper T |

| Width | 100-2200mm |

| Length | 100-16000mm |

| Process | Hot Rolled / Cold Rolled / Mill Finish |

| Processing Service | Bending, Welding, Decoiling, Punching, Cutting |

Features of film-coated aluminum coils:

1. Membrane aluminum panels provide a variety of color and texture options, suitable for different design styles and individual needs.

2. Its surface is covered with polyvinyl chloride film, which has excellent corrosion resistance and is suitable for long-term use in harsh environments.

3. The aluminum sheet has a high hardness surface, good wear resistance and is not susceptible to scratches and wear.

4. The surface is smooth, not easy to accumulate dust and dirt, and easy to clean and maintain.

5. The aluminum sheet base material and polyvinyl chloride film have excellent fire protection properties and meet the fire protection requirements of building materials.

Contact Us