Cruise Ship Funnels Built with 5083 Thick Aluminum Plate

In modern cruise ship design, the funnel, as the vessel’s exhaust system, plays a critical role. Aluminum alloy funnels made with 5083 aluminum plate are increasingly being chosen. Traditionally, funnels were mostly made of steel, which, while strong, is heavy, corrodes quickly, and requires frequent maintenance. In contrast, 5083 marine thick aluminum plate, with its light weight, corrosion resistance, and high-temperature durability, is becoming a new solution for cruise ship funnel construction.

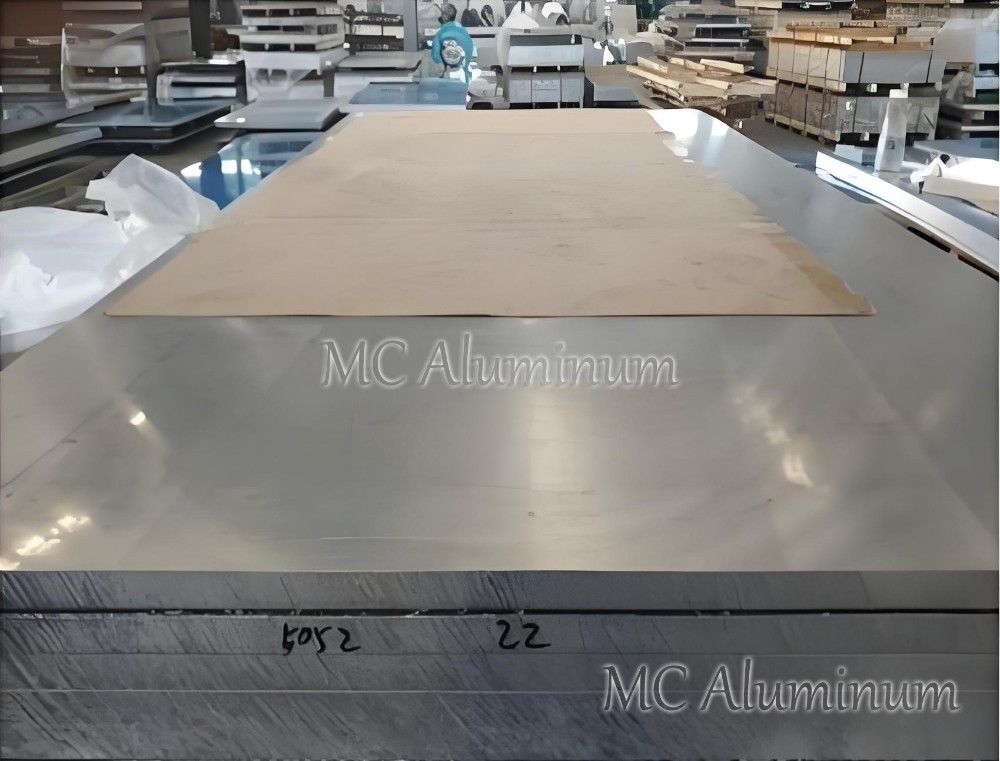

5083 belongs to the Al-Mg series of anti-rust aluminum alloys, featuring excellent corrosion resistance and good weldability. It is a typical marine-grade aluminum plate approved by classification societies such as ABS, DNV, LR, and CCS. Common tempers of 5083 marine aluminum plate include H116, H321, and O, with thicknesses ranging from 50-200 mm for heavy-duty ship structures.

Product Information

| Alloy | 5083 |

| Temper | H112, H116, H321, O, etc. |

| Thickness | 3-50 mm |

| Width | 100-2650 mm |

| Length | 1000-16000 mm |

| Welding Methods | TIG, MIG, FSW (Friction Stir Welding) |

| Surface Treatments | Sandblasting, anodizing, color coating, anti-corrosion coating |

| Applications | Yachts, fishing boats, workboats, etc. |

| MOQ | 1-3 tons |

Mechanical Properties

| Tensile Strength | 275-350 MPa |

| Yield Strength | ≥125 MPa |

| Elongation | ≥12% |

| Density | ~2.65 g/cm³ (only 1/3 of steel) |

| Corrosion Resistance | Excellent resistance to seawater and industrial atmospheric corrosion |

Advantages of Using 5083 Thick Aluminum Plate in Cruise Ship Funnels

Lightweight Design

Using 5083 aluminum plates can reduce funnel weight by more than 40%, significantly lowering the center of gravity of the superstructure and improving the ship’s roll stability—particularly beneficial for large cruise ships.

Superior Corrosion Resistance

5083 Al-Mg alloy demonstrates far better resistance to seawater and exhaust gas corrosion than carbon steel and low-alloy steels, greatly reducing maintenance intervals and the need for heavy anti-corrosion coatings.

Excellent Welding and Forming Performance

Whether TIG, MIG, or FSW, 5083 thick aluminum plates can achieve high-quality joints with efficiency up to 95%. When using 5356 welding wire in MIG welding, weld strength can reach 90% of the base material. Additionally, its excellent formability supports the manufacturing of complex funnel shapes.

Fatigue Resistance and Safety

Cruise ships operate under long-term exposure to complex sea conditions. The outstanding fatigue resistance of 5083 aluminum ensures funnel structures remain reliable under vibration and thermal cycling.

Aesthetic and Environmental Benefits

The aluminum surface can be finished with coatings, anodizing, or color treatments, meeting cruise ship branding and aesthetic needs. At the same time, aluminum alloys are recyclable, aligning with the green shipbuilding trend.

Engineering Practice

In large-scale European cruise projects, manufacturers have already applied 100–150 mm thick 5083-H321 aluminum plates in main funnel structures. Some shipyards also adopt modular prefabrication + FSW assembly, joining large aluminum plates into integrated funnel shells to reduce on-site welding work.

Contact Us