Dry-type transformer aluminum strip alloy number

Dry-type transformer aluminum strip has a high aluminum content (usually 99.6%-99.7% or more, while the electrical conductivity and thermal conductivity of aluminum are conventional metals that are only lower than copper, and the electrical conductivity of the metals is: silver, copper, gold, aluminum , nickel, steel alloy. Since the price of copper is much higher than that of aluminum, the most commonly used material for transformer strips is aluminum strips.

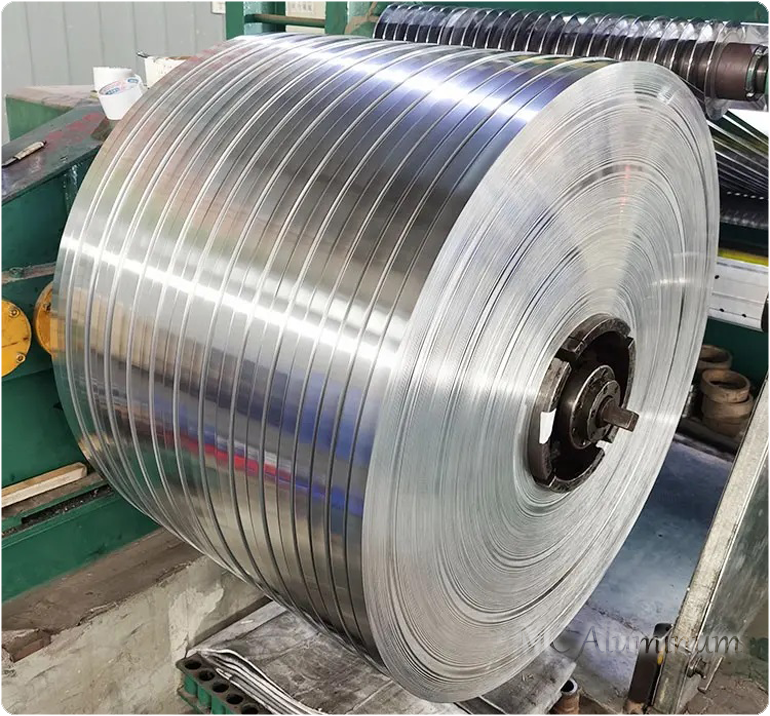

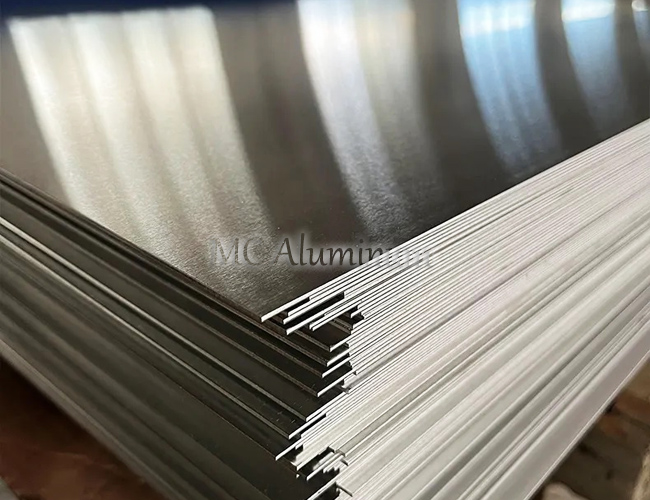

Transformer aluminum strip is the most important material for manufacturing high and low voltage windings of dry-type transformers, which directly affects the quality of transformers. Transformer aluminum strips generally use 1060 aluminum sheet, 1070 aluminum sheet and 3003 aluminum strips, which belong to the conventional series in the aluminum strip family. Series 1 and Series 3 aluminum plates are common aluminum plates, and the thickness of aluminum strips used for transformers is generally between 0.02-0.055mm.

Transformer aluminum tape has good elongation and tensile strength, which can fully meet the conventional processing requirements (stamping, stretching) and high formability. It is industrial pure aluminum, which has high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but its strength is low, and heat treatment cannot strengthen its machinability; it can be gas welded, hydrogen atom welded and contact welded, and it is not easy to braze; it is easy to withstand various A kind of pressure processing and extension, bending. Transformer aluminum strip is mainly used in large and medium-sized transformer manufacturing and related fields. The surface of the product is smooth, without scratches, and the edges can be chamfered (rounded corners, rounded edges), without burrs, which is better than the standard. Resistivity (conductivity) complies with transformer standards and industry standards. the

The application of transformer aluminum strips can make dry-type transformers have the advantages of small size, light weight, good insulation performance, flame retardancy, no pollution, small partial discharge, moisture resistance, stable and reliable operation, low noise, and low maintenance costs. It is widely used in buildings, underground facilities, commercial centers, residential areas, hotels and restaurants, and coastal humid areas.

MC Aluminum specializes in the production of aluminum strips for transformers, accepting orders for 1-200 tons of aluminum strips for transformers, customized on demand, price concessions, global export, welcome to consult and order!

Contact Us