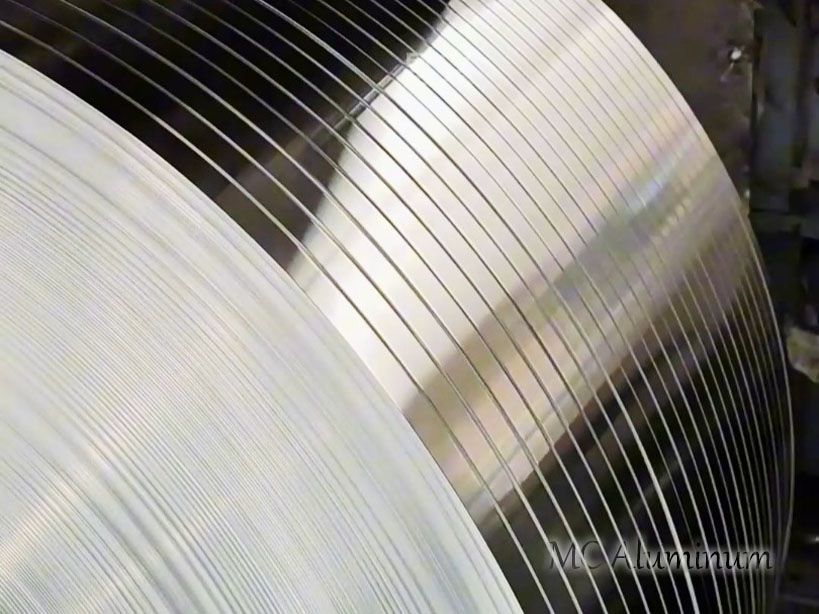

High quality thin aluminum strip 1060 1100 3003 3004 5052

Thin aluminum strip is a metal material made of high-purity aluminum or aluminum alloy with a small thickness and controllable width. It usually refers to aluminum materials with a thickness between 0.1mm-2mm and a width below 100mm, which are refined by rolling process. It plays an indispensable role in many industries due to its light weight, high conductivity, excellent corrosion resistance and easy processing.

Depending on the alloy elements, thin aluminum strip can be divided into multiple series, such as 1000 series, 3000 series, 5000 series and 8000 series, including 5083 aluminum alloy strip, 1060 aluminum strip, 1100 aluminum strip, 3003 aluminum strip, 3004 aluminum strip, 5052 aluminum alloy strip, etc. Commonly used states include O state (fully soft), H state (semi-hard), etc.

Aluminum strips of different materials have different performance characteristics. For example, 5083 alloy has good corrosion resistance and weldability, as well as medium strength; 3003 aluminum strip has high corrosion resistance, good formability and weldability.

Features of thin aluminum strip:

1. Lightweight and high strength: The density of aluminum is only 1/3 of that of steel. It is light in weight but high in strength, making it an ideal choice for lightweight design.

2. Excellent electrical and thermal conductivity: Aluminum has good electrical conductivity and thermal conductivity, and is widely used in electronics and heat dissipation.

3. Corrosion resistance: A layer of oxide film will naturally form on the surface of aluminum, which has excellent corrosion resistance.

4. Easy processing: Thin aluminum strip has good ductility and is suitable for various deep processing processes, such as stamping, cutting and bending.

5. Environmental protection: Aluminum strip can be fully recycled, meeting modern green environmental protection requirements.

Production process of thin aluminum strip:

Casting: Aluminum ingots are melted and cast into aluminum billets, laying the foundation for subsequent processing.

Hot rolling and cold rolling: Through multiple rolling processes, the aluminum is gradually rolled to the target thickness.

Intermediate annealing: Eliminate work hardening and improve the flexibility of aluminum.

Finishing rolling and slitting: Further adjust the thickness and width, and slit into the required size.

Surface treatment: Oxidation, electroplating or coating treatment is carried out according to needs to improve material performance and appearance quality.

Quality inspection: Through thickness, surface quality and performance tests, ensure that the product meets the standards.

Thin aluminum strips are widely used in many fields due to their unique properties:

Electronic field: used for the production of capacitor foil, electronic components, etc., because of its good conductivity and light weight.

Construction field: used for the production of aluminum alloy doors and windows, curtain walls, ceilings, etc., because of its light weight, corrosion resistance and easy processing characteristics.

Aviation field: used for aircraft shells, wings, engines and other parts, because of its high strength and light weight.

Packaging field: used for beverage bottle caps, food packaging, etc., because of its good barrier properties and light weight.

Insulation field: used for pipe and equipment insulation, because of its good thermal insulation performance.

Transportation: Used in vehicle body structural parts such as automobiles and subway vehicles due to their light weight and high strength.

Contact Us