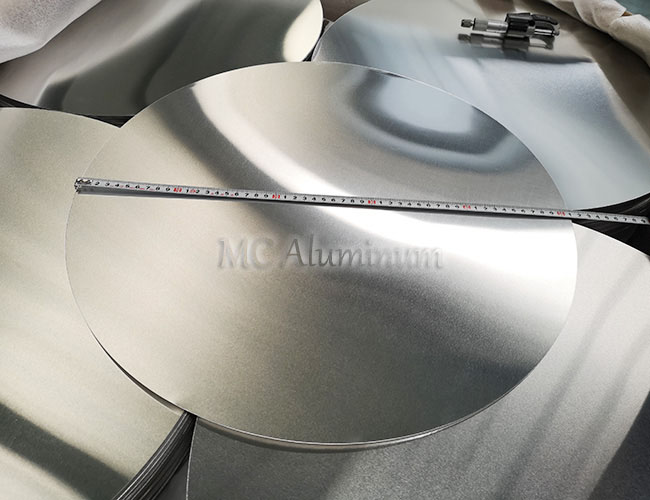

Hot rolled aluminum sheet

What is hot rolling?

Hot rolling is an aluminum ingot cast into a slab with a thickness of 300-500mm. It is rolled above the recrystallization temperature. After heating, it is rolled on the hot rolling equipment to products of various thicknesses (finish rolling is required in the later stage) ). Hot rolled products have high corrosion resistance, fatigue resistance and strong plasticity.

Hot rolled aluminum sheet classification:

1. Hot-rolled thick sheets: aluminum and aluminum alloy sheets with a thickness of not less than 7.0mm. The main varieties include hot-rolled sheets, annealed sheets, quenched or quenched pre-stretched sheets, etc. Hot-rolled thick sheets are usually produced by the block method on hot rolling mills. The traditional process is: ingot homogenization-milling-heating-hot rolling-cutting to length-straightening.

2. Hot-rolled coils: Aluminum and aluminum alloy sheets and strips with a thickness less than 7.0 are usually produced by hot-rolled coils. The products are mainly used as cold-rolled billets and also used to produce sheets. The modern production process is: ingot milling —Heating (Integrated Soaking and Heating) —Hot Rough Rolling—Hot Rolling—Bundling and Weighing Analysis of the Hot Rolling Process of Aluminum sheet.

Features of hot rolling:

1. Low energy consumption, good plastic processing, low deformation resistance, no obvious work hardening, easy rolling, and reduced energy consumption required for metal deformation.

2. Hot rolling usually uses large ingots and large rolling reductions. The production pace is fast and the output is large, which creates conditions for large-scale production.

3. The cast structure is transformed into a processed structure through hot rolling, and the plasticity of the material is greatly improved through the transformation of the structure.

4. The characteristics of the rolling method determine the anisotropy of the properties of the rolled sheet. First, there are obvious performance differences in the longitudinal, transverse and high directions of the material. Second, there are deformation textures and recrystallization textures. During punching There is obvious directionality in control performance.

Contact Us