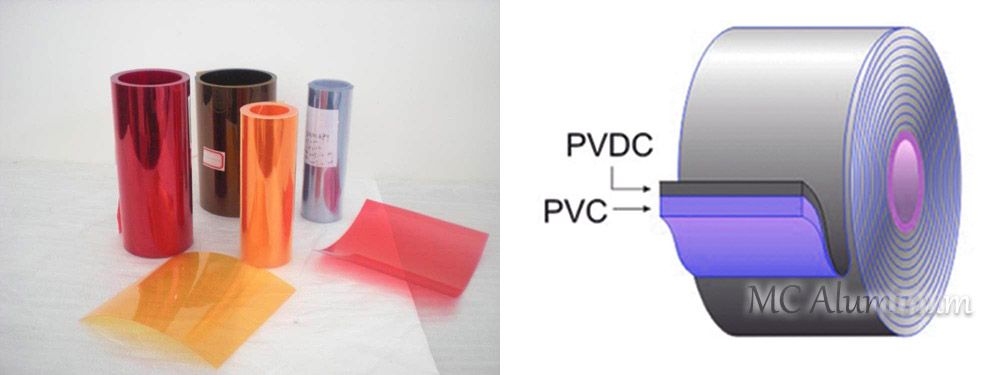

Pharmaceutical hard blister PVC / PVDC composite rigid film

PVC & PVDC rigid film is a composite film material commonly used for pharmaceutical packaging, with excellent moisture-proof, barrier properties and good mechanical strength. This material is mainly used for blister packaging of medicines, which can effectively protect medicines from the influence of the external environment, especially moisture and oxygen. Compared with PVC rigid film materials of the same thickness, the oxygen barrier performance of PVC/PVDC composite rigid film is improved by 10 times, and the water vapor barrier performance is improved by 5-10 times.

PVDC coated PVC most common specifications:

PVC / PVDC: 250 micron PVC / 40 gsm PVDC

PVC / PVDC: 250 micron PVC / 60 gsm PVDC

PVC / PVDC: 250 micron PVC / 90 gsm PVDC

PVC / PVDC: 300 micron PVC / 40 gsm PVDC

PVC / PVDC: 300 micron PVC / 60 gsm PVDC

PVC & PVDC rigid film specifications:

| PVC thickness | 200 and 250mic,etc |

| PVDC coating | 40, 60, 90 or 120g/m2 |

| Color | transparent, transparent white, opaque yellow, orange, red, green, silver |

| Inner core diameter | 76 mm |

| Roll outer diameter | ≤500 mm |

| Function | Blister, easy to form, heat seal |

| Application | Tablets and capsules |

Features of PVC/PVDC composite rigid film:

1. High barrier property: PVC/PVDC composite rigid film has extremely high water vapor and oxygen barrier properties, which can effectively prevent the drug from deliquescing, mildewing and oxidative failure, and extend the shelf life of the drug. Its barrier effect can be precisely controlled by adjusting the coating amount of PVDC.

2. Excellent physical properties: The product thickness is uniform, clear and transparent, and the coating is uniform without obvious bonding or cast lines. At the same time, the material also has good impact resistance, corrosion resistance, aging resistance, UV resistance and radiation resistance.

3. Moderate flexibility and rigidity: PVC/PVDC composite rigid film has similar flexibility and rigidity to PVC rigid film, and the use parameters are also consistent with PVC rigid film, which is suitable for ordinary blister aluminum-plastic packaging machines.

4. Safe and non-toxic: Low content of vinyl chloride monomer and low index of easy oxidation ensure the safety and non-toxicity of the material, which meets the relevant standards of pharmaceutical packaging materials.

5. Easy processing: PVC/PVDC composite rigid film is easy to process and can adapt to different packaging needs, such as blister packaging, etc., and is not easy to break during use, ensuring the safety of drugs during transportation and storage.

6. Heat sealability: PVC/PVDC composite rigid film has good heat sealing performance and can be closely combined with heat sealing materials such as blister aluminum foil to create a separate blister for each drug, ensuring the hygiene and sealing of the packaging.

7. Chemical resistance: PVC/PVDC composite rigid film can resist the erosion of chemical substances to a certain extent, maintain the integrity and stability of the packaging, and is suitable for the packaging needs of a variety of drugs.

Contact Us