What is the Hardness of 5086-H111 Aluminum Plate?

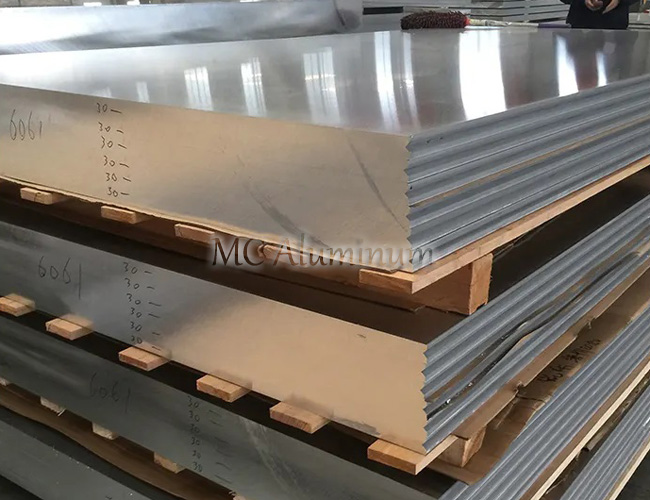

In the fields of shipbuilding, transportation, and structural engineering, 5086 aluminum alloy is widely used due to its excellent corrosion resistance, strength, and weldability. MC Aluminum supplies 5086 aluminum plates in thicknesses ranging from 0.5 to 50mm and widths from 100 to 2500mm. Common tempers include O, H111, H32, H34, and H116.

What is 5086-H111 Aluminum Plate?

5086 aluminum alloy belongs to the Al-Mg (aluminum-magnesium) series of anti-corrosion aluminum alloys. Its main alloying element is magnesium (Mg), which gives it excellent resistance to seawater corrosion and moderate strength. It is widely used in shipbuilding, vehicle structures, and pressure vessels.

The H111 temper refers to aluminum that has been slightly strain-hardened after annealing. Compared to the fully annealed O temper, H111 offers slightly higher strength while retaining good ductility and excellent weldability.

Specifications of 5086 Aluminum Plate:

| Alloy | 5086 |

| Temper | O, H111, H32, H34,H116,etc |

| Thickness | 1.0mm – 20mm (commonly 2mm, 3mm, 5mm, 8mm, 10mm) |

| Width | 1000mm – 2000mm (commonly 1220mm, 1500mm) |

| Length | 2000mm – 6000mm (customizable) |

| Surface | Mill finish, brushed, tread plate, etc. |

| Processing | Cold rolled or hot rolled |

| Forms | Sheet, coil, or cut-to-size pieces |

| MOQ | 1-3 tons |

Chemical Composition of 5086 Aluminum Alloy (Typical %):

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Single | Al |

| 5086 | 0.4 | 0.5 | 0.1 | 0.2-0.7 | 3.5-4.5 | 0.05-0.25 | 0.25 | 0.15 | 0.05 | 0.15 | Remainder |

Mechanical Properties of 5086 Aluminum Plate:

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Brinell Hardness (HB) | Features |

| O | 240–290 | 95-125 | ≥20 | 45-55 | Soft state, excellent formability |

| H111 | 115-145 | ≥14 | 60-70 | Good formability, suitable for welded structures | |

| H32 | 275–345 | ≥240 | ≥10 | 80-95 | Higher strength, good corrosion resistance |

| H34 | 310-370 | ≥275 | ≥8 | 95-110 | Higher strength, slightly reduced ductility |

| H116 | 275-350 | ≥240 | ≥10 | 80-95 | High strength, excellent marine corrosion resistance |

Performance Advantages of 5086-H111 Aluminum Plate:

1. Corrosion Resistance:

5086 aluminum alloy exhibits exceptional resistance to corrosion in marine environments. A dense oxide film forms on its surface, effectively resisting salt spray and seawater erosion. It is particularly suitable for hull bottoms, stern plates, and other components exposed to harsh corrosive conditions. Compared to 3003 alloy, 5086 shows over 50% improvement in salt spray resistance, extending service life by 3–5 times.

2. Excellent Weldability:

Supports multiple welding methods including arc welding and gas welding. Welded joints are crack-resistant and retain good strength.

3. High Strength:

The H111 temper offers medium strength and good toughness, balancing load-bearing capacity and impact resistance.

4. Eco-Friendly:

100% recyclable with up to 70% lower carbon emissions than steel, aligning with sustainable and green manufacturing trends.

By optimizing the magnesium content and processing methods, 5086-H111 aluminum plate achieves a well-balanced combination of corrosion resistance, weldability, and strength, making it an ideal material for lightweight marine equipment and transportation structures.

As a leading manufacturer of aluminum plates in China, MC Aluminum specializes in producing 1xxx–8xxx series aluminum sheets and coils. We offer a full range of models, customized services, fast delivery, and competitive prices. Overseas export and sample requests are welcome. We invite new and existing customers to visit our facility for cooperation and business discussions.

Contact Us