Why do aluminum coils need to be cleaned? -MC Aluminum

At present, most of the aluminum coil users have certain requirements on the surface finish of the aluminum coil, and they all require the aluminum coil to be cleaned and oiled to correct the flatness.

In the process of cold-rolling the aluminum coil, due to the corresponding friction and rolling between the surface of the roll and the aluminum plate, the surface will produce fine alumina powder falling off and adsorption, the rolling oil and the accompanying suspended components. It will remain on the surface of the aluminum coil, which will actually have a very adverse effect on the processing of the product itself, such as compounding and painting.

During stretch-bending and straightening, due to the severe bending deformation of the strip on the roller, part of the tension applied to the strip is converted into the pressure of the strip on the tension roller, and finally a friction force is formed, which drives the roller group. If the surface of the coil is not cleaned, the alumina powder will fall off when it is deformed, and it will be attached to the roller surface of the tension roller along with the oil stains, which will cause the roller surface to wear and cause slight damage to the aluminum plate. Therefore, professional aluminum coil cleaning work is very important.

Aluminum coil cleaning is to use a pressure pump to pressurize the cleaning medium to perform non-contact spray cleaning or contact brushing on the surface of the strip, so that the aluminum powder oil on the surface of the material dissolves and falls off into the cleaning medium, and then is squeezed and dried by a squeeze roller. High pressure air blowing and even high temperature air drying to obtain clean and dry aluminum coils. At the same time, by continuously replenishing the cleaning medium and using the online circulating filter system at the same time, the cleaning medium can be kept in sufficient quantity and clean, and the heat energy and cleaning medium can be greatly saved. At present, the commonly used cleaning media for stretch-bending straighteners in the aluminum coil processing industry include cleaning agents (or solvent oil), softened hot water, and chemical solvents.

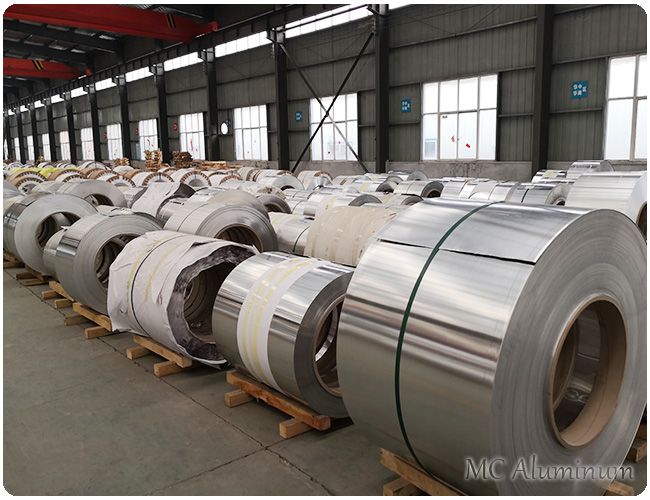

MC Aluminum specializes in the production of various specifications of aluminum sheets, aluminum coils, aluminum circles and other aluminum products, welcome to order!

Contact Us