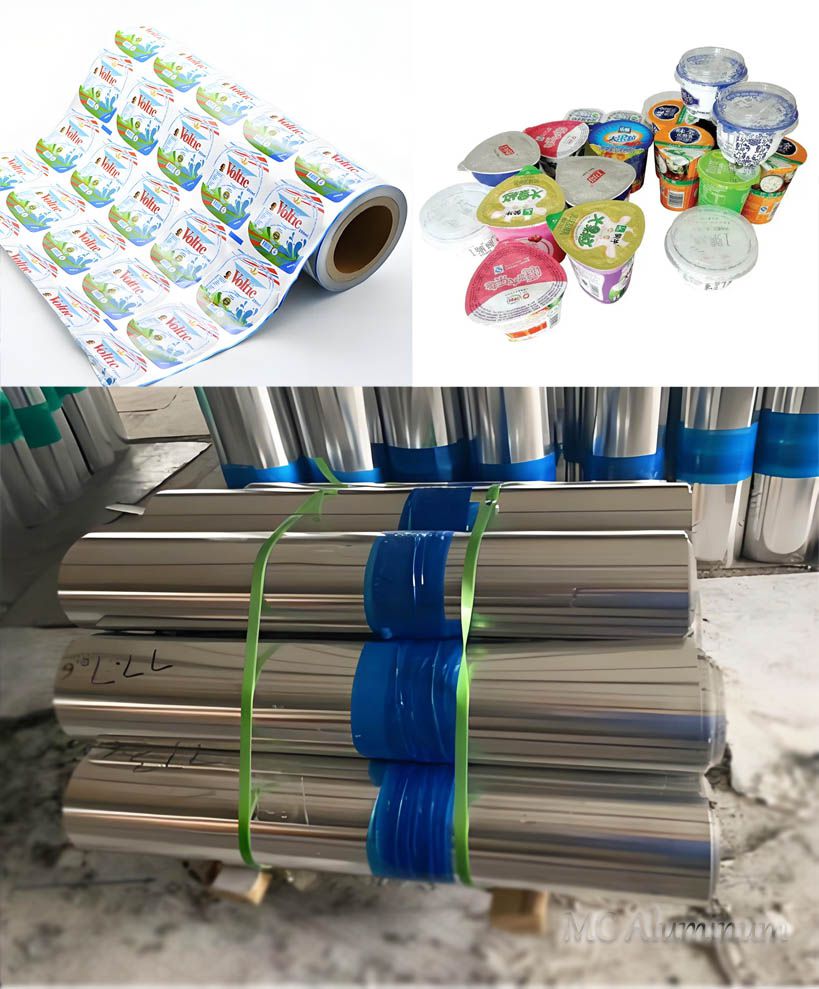

Yogurt Lid with 8011-O Aluminum Foil

In daily life, when we drink yogurt, we always peel off the aluminum foil lid, but few people pay attention to its material. In fact, most yogurt lid films use 8011-O aluminum foil, a specialized aluminum alloy material for food packaging.

What is 8011-O Aluminum Foil?

8011-O aluminum foil is an aluminum alloy foil, where 8011 represents the alloy grade, and O temper indicates that it has undergone annealing treatment to achieve a soft state. Compared to other aluminum alloys, it offers better ductility, sealing performance, and corrosion resistance, making it widely used in food packaging, pharmaceutical packaging, and household aluminum foil applications.

8011 Aluminum Closure Lid Specifications:

| Structure | Polyester / Aluminum Foil / Heat Sealing Layer (PET / AL / PE·EVA) |

| Alloy | 8011 |

| Temper | O |

| Thickness | 100-1600mm |

| Length | C |

| ID | 76/152 mm |

Features of 8011-O Aluminum Sealing Foil for Yogurt Sealing:

1. Excellent Sealing Performance

8011-O aluminum foil can be heat-sealed or coated with plastic film to form an airtight seal, preventing bacteria, oxygen, and moisture from entering, thereby ensuring the freshness of yogurt.

2. Superior Corrosion Resistance

It has excellent acid and alkali resistance, preventing any reaction between the yogurt and aluminum foil, ensuring food safety.

3. Good Flexibility and Easy-to-Tear Property

Annealed aluminum foil has good ductility and toughness, maintaining moderate strength during sealing while allowing for easy lid removal.

4. Food-Grade Safety Standards

Non-toxic and odorless, it complies with FDA and EU EFSA food safety standards, ensuring packaging safety.

5. Suitable for Various Printing Processes

It supports color printing and coating treatments, enhancing brand image and anti-counterfeiting effects.

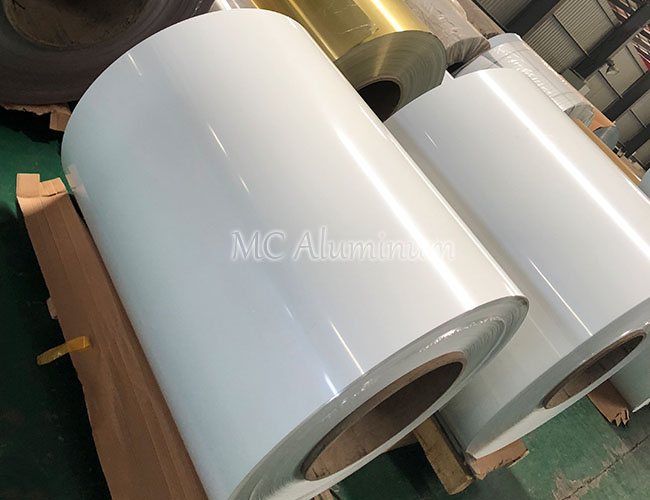

Production Process of 8011-O Aluminum Foil for Yogurt Lids:

1.Casting & Hot Rolling: Aluminum ingots are melted and processed through casting or hot rolling to form preliminary aluminum foil rolls.

2.Cold Rolling: Reduces foil thickness further and enhances mechanical properties.

3.Annealing Treatment: Adjusts the softness of the aluminum foil, achieving O temper (soft state).

4.Surface Coating: Can be coated with food-grade layers such as PE, PP, or heat-sealing glue to improve sealing performance.

5.Printing & Die-Cutting: Branding logos and designs are printed on the foil, followed by cutting it into sizes suitable for yogurt cup lids.

Why Choose MC Aluminum for 8011-O Yogurt Lid Foil?

MC Aluminum is a large-scale aluminum foil raw material manufacturer. Our 8011-O aluminum foil is widely used for yogurt sealing films. Our yogurt lid aluminum foil has few pinholes, excellent barrier properties, and strong heat-sealing performance. Additionally, the foil is oil-free, clean, and meets food-grade standards, making it safe for high-temperature sterilization and hygienic use. Our products are stable in quality, exported globally, and competitively priced—a reliable choice for your purchase!

Contact Us