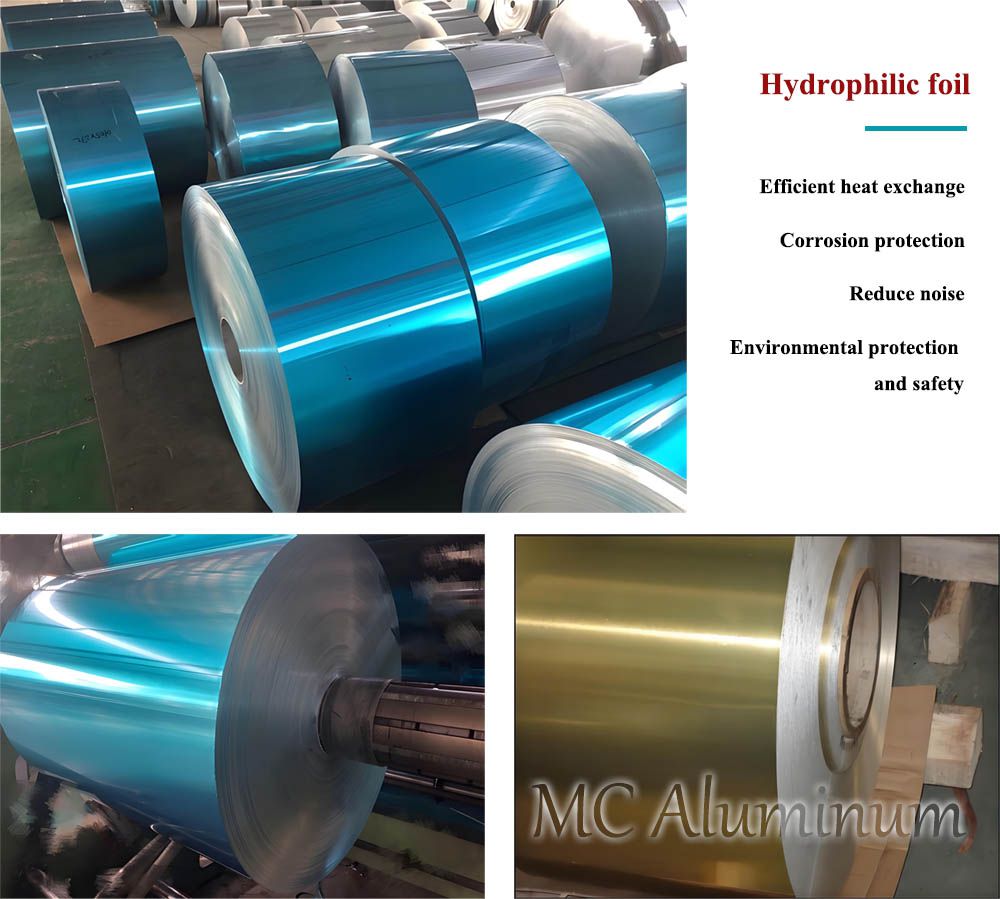

Hydrophilic Aluminum Foil for Air Conditioner Radiators

In the modern air conditioning manufacturing industry, improving heat exchange efficiency, reducing energy consumption, and extending equipment lifespan are core concerns. A major home appliance manufacturer, while developing a new generation of high-efficiency air conditioners, sought to use superior heat dissipation materials to enhance product competitiveness. In this context, hydrophilic aluminum foil became the ideal solution.

Material and Coating of Hydrophilic Aluminum Foil

Hydrophilic aluminum foil mainly adopts high-strength, corrosion-resistant aluminum alloys to ensure excellent heat exchange performance and long-term stability in high-humidity environments. The surface is coated with a hydrophilic layer (organic resin coating, inorganic oxide coating, or antibacterial coating) through a special process, allowing condensate water to disperse quickly and preventing water droplet accumulation. Common aluminum alloy grades include 8011 aluminum foil, 1100 aluminum alloy, and 3102 aluminum alloy.

8011 Aluminum Alloy

Main Composition: High aluminum (Al) content, with small amounts of iron (Fe) and silicon (Si).

Features: Excellent corrosion resistance, formability, and mechanical strength, widely used in air conditioner fins.

1100 Aluminum Alloy

Main Composition: Over 99% pure aluminum (Al) with minimal other elements.

Features: Outstanding ductility and thermal conductivity, though relatively lower in strength, suitable for applications requiring flexibility and heat dissipation.

3102 Aluminum Alloy

Main Composition: Aluminum (Al) base with small amounts of manganese (Mn) to enhance corrosion resistance.

Features: Balanced corrosion resistance and mechanical strength, commonly used in high-efficiency radiators.

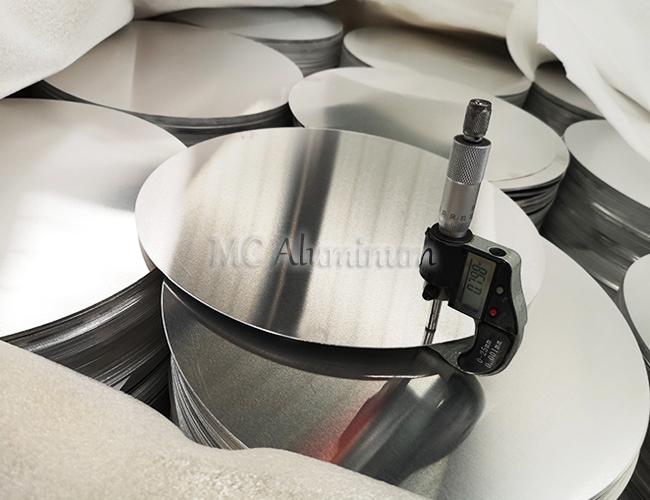

Specifications of Hydrophilic Aluminum Foil for Air Conditioner Radiators

| Alloy | 8011, HL01, HL02, 1100, 3102 |

| Temper | H22, H24, H26, O |

| Thickness | 0.095-0.20mm |

| Width | 270-1070mm |

| Length | C |

| ID | Φ75mm, Φ150mm, Φ200mm, Φ300mm |

| Color | Blue, Gold |

| Applications | Household air conditioners, central air conditioners, automotive air conditioners, train air conditioners, and other heat exchanger fins for air conditioning systems. Hydrophilic aluminum foil is mainly used in condensers and evaporators. |

Performance Characteristics of Hydrophilic Aluminum Foil for Heat Exchangers

1.High-Efficiency Heat Exchange: The hydrophilic layer increases the heat exchange area, accelerating cooling and heating speed, improving heat exchange efficiency by 5%-15%.

2.Corrosion and Mold Resistance: Hydrophilic aluminum foil has excellent corrosion resistance, extending the lifespan of air conditioners and preventing mold growth, thus improving air quality.

3.Noise Reduction: Prevents condensate water from obstructing airflow and reduces vibration-induced noise.

4.Anti-Frost Performance: Reduces frost formation, enhancing heating efficiency in winter, decreasing defrosting frequency, and improving energy savings.

5.Eco-Friendly and Safe: The hydrophilic coating is made of environmentally friendly materials, free from harmful substances, compliant with RoHS and REACH standards, ensuring safety for humans and the environment.

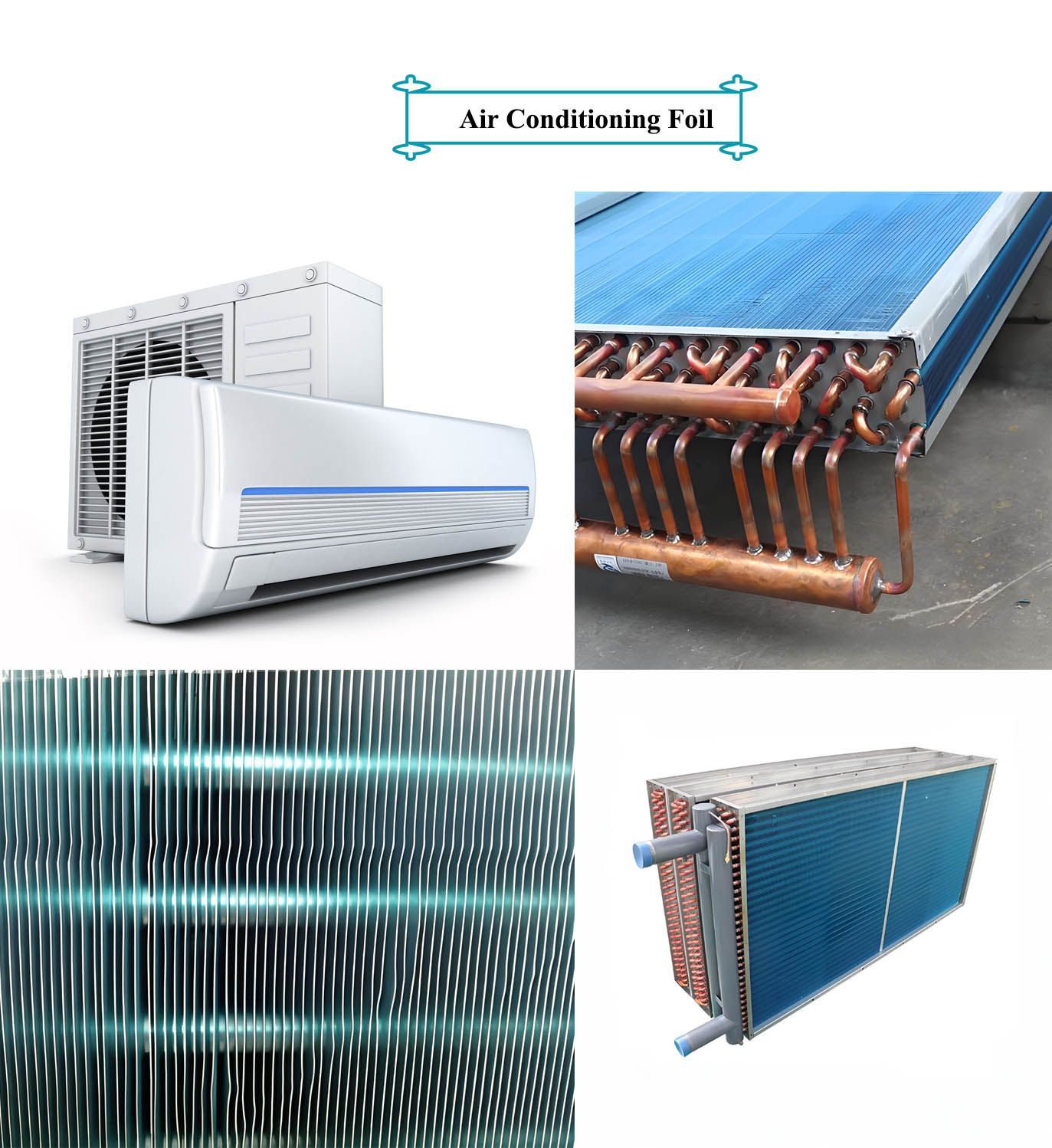

Application Fields of Hydrophilic Aluminum Foil

1.Household Air Conditioners: Enhances heat exchange efficiency, reduces energy consumption, and improves user comfort.

2.Central Air Conditioners: Suitable for commercial and industrial air conditioning systems, ensuring long-term stability.

3.Automotive Air Conditioners: Improves condenser heat dissipation, reducing fuel consumption.

4.Air Purification Equipment: Applied in air heat exchange systems to improve purification efficiency.

As a professional aluminum processing manufacturer, MC Aluminum specializes in producing aluminum foil for air conditioner heat exchangers, including 8011 aluminum foil, 3102 hydrophilic aluminum foil, blue-coated hydrophilic aluminum foil, gold-coated hydrophilic aluminum foil, aluminum fins, and more. Our products feature clean, oil-free surfaces with no black streaks or marks. MC Aluminum exports products to multiple overseas markets, offering reliable after-sales service, competitive pricing, fast delivery, and massive production capacity.

Contact Us