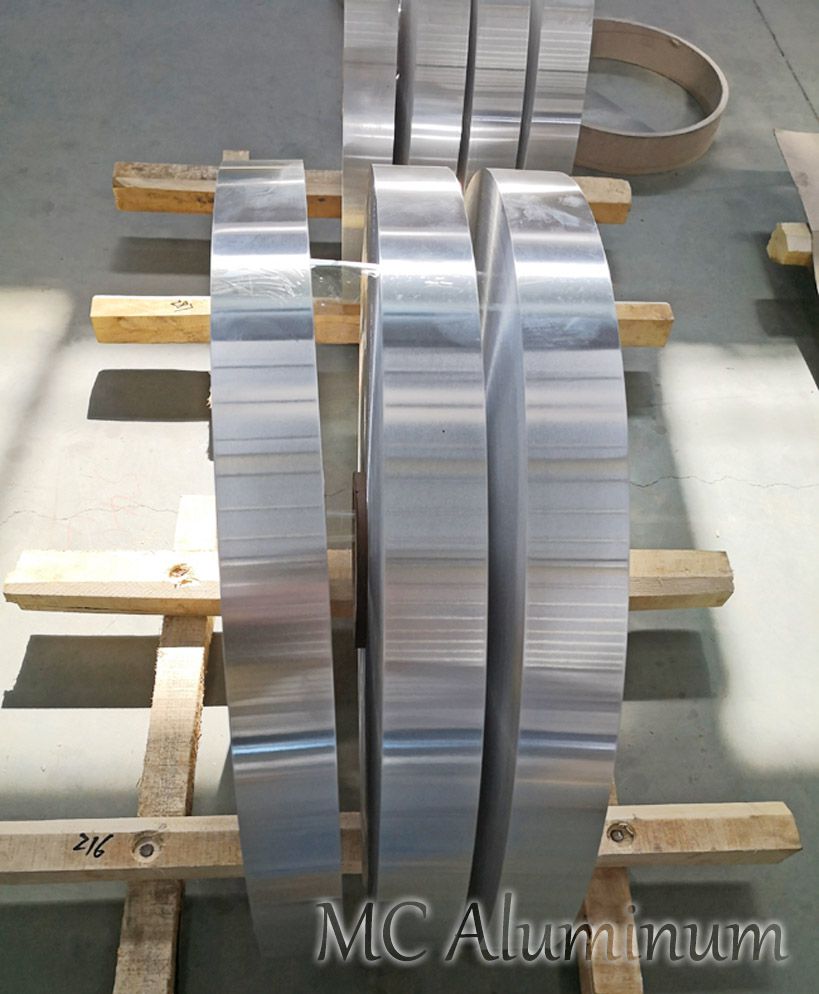

1 / 3 / 5 series flat aluminum strip manufacturer

Flat aluminum strip is a flat strip material made of pure aluminum or aluminum alloy, which has good electrical conductivity, corrosion resistance and easy processing. According to different materials and uses, flat aluminum strip can be divided into many types, such as 1060 aluminum strip, 1100 aluminum strip, 3003 aluminum strip, 3004 aluminum strip, 5052 aluminum strip, etc.

Flat aluminum strip specifications:

| Temper | O H12 H22 H14 H24 H16 H26 H18, etc |

| Thickness | 0.06-3mm |

| Width | 12-1240mm |

| Length | up to 3000mm |

| Cad | 5%~20% |

| ID(mm) | 75 150 200 300 500 |

| Outer diameter | up to 1800mm |

| Coil weight | up to 8000KG |

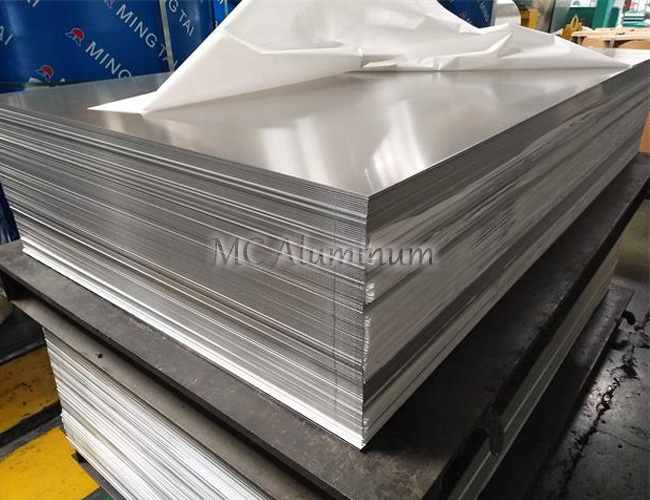

Features of flat aluminum strips:

1. Lightweight material: Aluminum has a low density, which is convenient for transportation and processing.

2. Good electrical and thermal conductivity: Suitable for applications related to electrical and thermal conduction.

3. Strong corrosion resistance: The aluminum oxide layer formed on the surface can protect the material from oxidation and corrosion.

4. High plasticity: Easy to cut, bend and shape, suitable for different needs.

5. Aesthetics: Surface treatment (such as polishing, anodizing) can be performed to improve the decorative effect.

Flat aluminum strip production process:

1. Raw material preparation: Select high-quality aluminum ingots as raw materials to ensure that the aluminum ingots are free of defects such as inclusions and pores.

2. Melting: Put the aluminum ingot into the melting furnace and melt it by high temperature heating. The furnace temperature and melting time need to be strictly controlled during the melting process to ensure that the composition of the aluminum liquid is uniform and the temperature is moderate.

3. Casting: The molten aluminum liquid is poured into the mold through the casting machine and condensed to form an aluminum billet. The condensation speed and mold temperature need to be controlled during the casting process to ensure the quality of the aluminum billet.

4. Rolling: Put the aluminum billet into the rolling mill and press it into an aluminum strip with uniform thickness through the rolling action of the roller. The rolling force and rolling speed need to be controlled during the rolling process to ensure the thickness and quality of the aluminum strip.

5. Annealing and finishing: The rolled aluminum strip is annealed to eliminate internal stress and improve plasticity and toughness. Then trimming, shearing, straightening and other finishing treatments are carried out to ensure that the dimensional accuracy and surface quality of the aluminum strip meet production requirements.

Application of aluminum alloy strips:

1. Cables and optical cables: Flat aluminum strips are often used in the manufacture of cables and optical cables as conductive materials and anti-corrosion layers due to their excellent electrical conductivity and good corrosion resistance.

2. Chemical equipment: Some types of flat aluminum strips (such as 1060 aluminum strips) have high requirements for corrosion resistance and formability in the working environment, so they are widely used in the manufacture of chemical equipment.

3. Food industry: Some types of flat aluminum strips (such as 1100 aluminum strips) have good corrosion resistance and formability, and are suitable for the processing of devices and storage containers in the food industry.

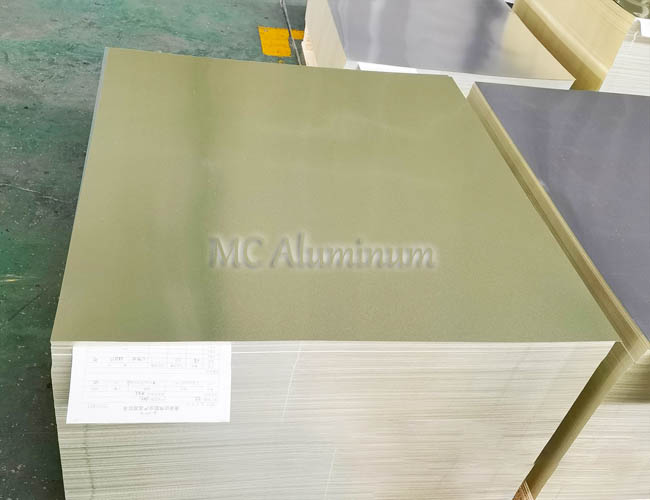

4. Architecture and decoration: Flat aluminum strips can be used for building curtain walls, decorative strips, edge strips, etc., providing beautiful and durable decorative effects.

Contact Us