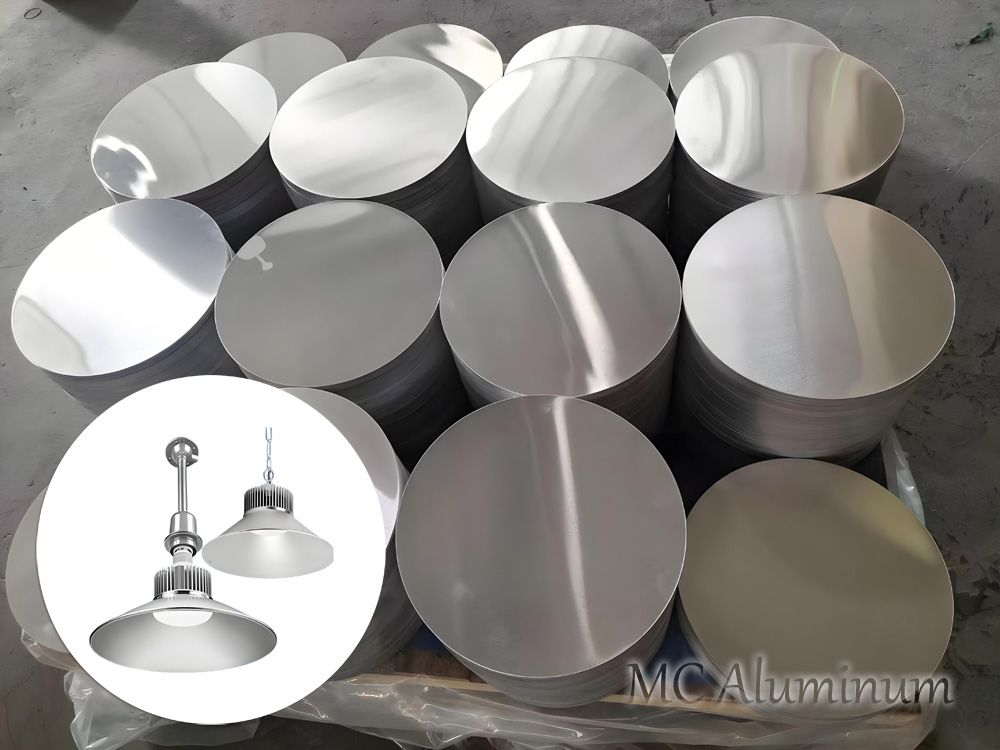

1050-O, 1060-O, 1100-O Spinning Aluminum Discs for Lampshades

With the increasing demand for lightweight, aesthetic, and environmentally friendly lighting solutions, aluminum has gradually become the preferred material for lampshade manufacturing. Among them, 1050-O, 1060-O, and 1100-O spinning aluminum circle discs are widely used in residential, commercial, and industrial lighting due to their excellent workability and attractive surface finish.

Spinning is a point-forming plastic processing technology. The pre-cut O-temper aluminum disc is fixed on the spinning machine mold. As the mold rotates, the roller applies pressure to the disc, gradually forcing it to fit the mold shape, and finally forming a seamless, hollow, rotationally symmetric lampshade.

1050, 1060, and 1070 aluminum circles in O temper have strong toughness, are not prone to cracking during spinning, and are suitable for manufacturing lampshades with complex curved shapes. At the same time, they allow secondary surface treatments such as anodizing, painting, and polishing, which improve both the appearance and durability of the lampshade.

Common Aluminum Alloys for Lampshades

The commonly used aluminum disc alloys for lampshades include 1050-O, 1060-O, and 1100-O. Since lampshades are produced through stamping and spinning, O-temper aluminum discs with better ductility are more suitable for such forming processes. They are the best choice for achieving complex, deep-drawn lampshade geometries.

1050-O Aluminum Disc

With an aluminum content of 99.5%, 1050-O has high purity, excellent ductility, and strong corrosion resistance. It is particularly suitable for lampshades with extremely deep drawing requirements and complex designs. When designers aim for smooth, continuous curves that demand significant material flow, 1050-O is the safest and most reliable choice. After anodizing, it provides the purest and brightest surface finish.

1060-O Aluminum Disc

Containing 99.6% aluminum, 1060-O offers slightly higher purity and strength compared to 1050. It has excellent formability and is considered the most common and versatile material for spun lampshades. In most projects requiring high formability, 1060-O is an economical and dependable option.

1100-O Aluminum Disc

1100 belongs to industrial pure aluminum with 99.0% aluminum content. Its strength is slightly higher than 1050 and 1060, while ductility is slightly lower. It is suitable for lampshades that require a certain level of structural strength-for example, shades that also serve as partial supports or need better resistance to minor impacts. As long as the spinning shape is not extremely complex, 1100-O strikes a balance between formability and durability.

Other Tempers Available

1050-O/H12/H14/H16/H18/H111/H112 aluminum circles

1060-O/H12/H14/H16/H18/H111/H112 aluminum circles

1100-O/H12/H14/H16/H18/H111/H112 aluminum circles

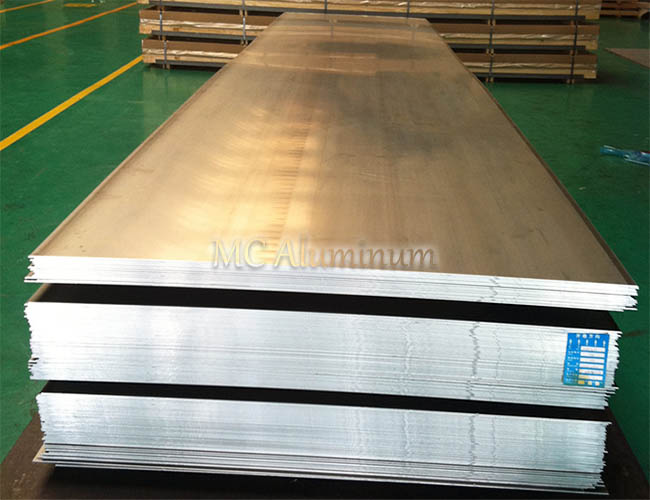

Product Specifications for Lampshade Aluminum Blanks

| Alloys | 1050, 1060, 1100, etc. |

| Temper | O, H12, H14, H16, H18, H111, H112 |

| Thickness | 0.5mm - 6.0mm |

| Diameter | 100mm - 1200mm |

| Surface Finish | Bright, brushed, anodized, coated |

| Production Process | CC/DC |

| Applications | Lampshades, cookware, traffic signs, electronic components, etc. |

| Samples | 1-3 pieces available |

| MOQ | 1-3 tons |

Advantages of Aluminum Discs for Lampshades

Lightweight: Alloys 1050, 1060, and 1100 have low density, resulting in lightweight lampshades that are easy to install, especially suitable for large lighting fixtures such as chandeliers and ceiling lamps.

Excellent ductility: High purity ensures unmatched plasticity, making them ideal for spinning, deep drawing, and other cold forming processes to achieve complex lampshade shapes.

Strong corrosion resistance: A natural oxide film forms on the aluminum surface, protecting it from air, moisture, and pollutants, extending the service life of the lamp.

Good optical properties: Aluminum has a high reflectivity. After polishing or anodizing, it enhances light efficiency and reduces energy loss.

Electrical and thermal conductivity: For modern LED lighting, aluminum lampshades can also serve as heat sinks, dissipating heat effectively and prolonging the lifespan of light sources.

Eco-friendly and recyclable: Aluminum has a high recycling rate, and waste can be reused, aligning with the green lighting trend.

Multiple surface treatments: Options include anodizing (silver, black, gold, etc.), coating, brushing, and mirror polishing, meeting diverse aesthetic requirements for lighting.

MC Aluminum, as a large aluminum circle disc manufacturer, specializes in the production of 1/3/4/5/8 series aluminum circles, which are widely used in cookware, traffic signs, lampshades, etc. Our products are of stable quality and are exported to many countries overseas. We have large production capacity, short delivery time, and provide professional after-sales service. You can order with confidence.

Contact Us