3003 / 4343 Aluminum Strip for Automotive Radiators

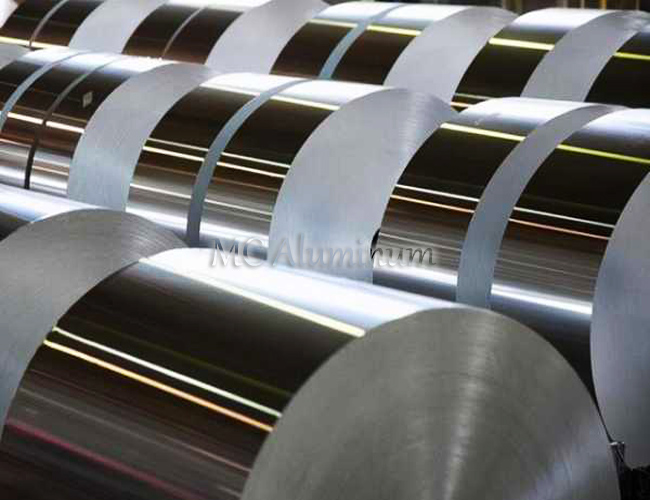

Since the early 1990s, the demand for lightweight and highly efficient heat dissipation materials has been increasing. Aluminum strip has gradually become widely used in automotive radiator heat dissipation applications. In major automotive radiator manufacturing hubs, such as Chiping District in China, aluminum automotive radiator production has become a key industry. Aluminum strip is widely recognized in international markets due to its excellent thermal conductivity, strength, corrosion resistance, and low density, which contribute to the lightweight design of radiators.

Common Aluminum Strip Materials for Automotive Radiators

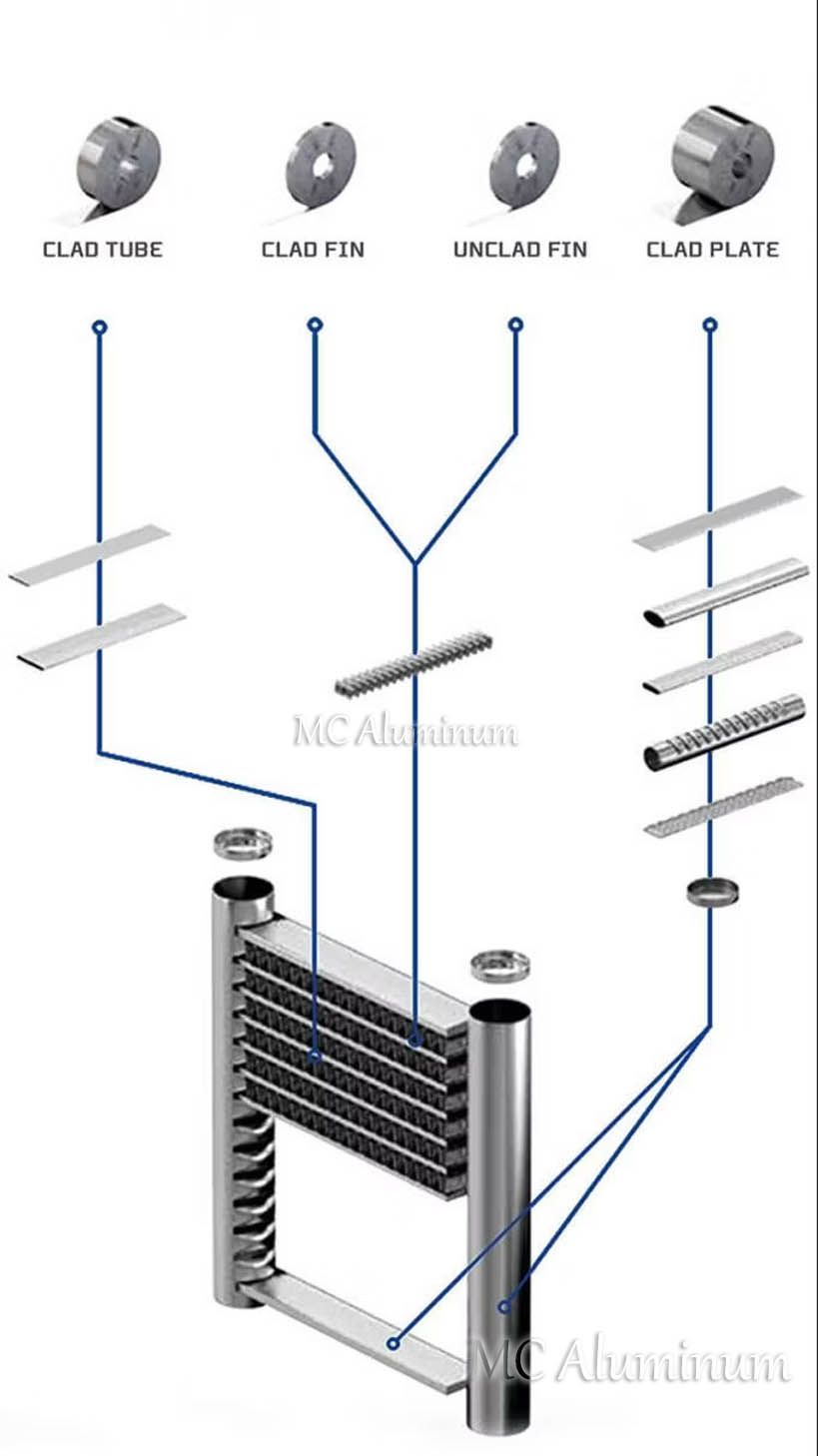

3003 Aluminum Strip: Known for its excellent formability and corrosion resistance, with moderate strength, making it ideal for automotive radiators. It can be processed into various shapes and structures to meet radiator performance and structural strength requirements.

4343 Aluminum: A silicon alloy aluminum with a lower melting point and good flowability. It is mainly used as a brazing material to connect the radiator core and fins, ensuring good welding performance and sealing properties.

Specifications of Aluminum Sheet Strip for Radiators

| Alloy | 3003, 4343, etc. |

| Temper | O, H14, H16, H18, H22, H24, etc. |

| Thickness | 0.09mm - 0.6mm |

| Width | 30mm - 900mm |

| Cladding Rate | 8%-12% per side or customized as per customer requirements |

| ID | 152mm, 200mm, 300mm, etc. |

| OD | 900mm - 1350mm |

| Applications | Widely used in manufacturing radiators, condensers, evaporators, heat exchangers, intercoolers, engine oil coolers, etc. |

| MOQ | 1-3 tons per model (trial order) |

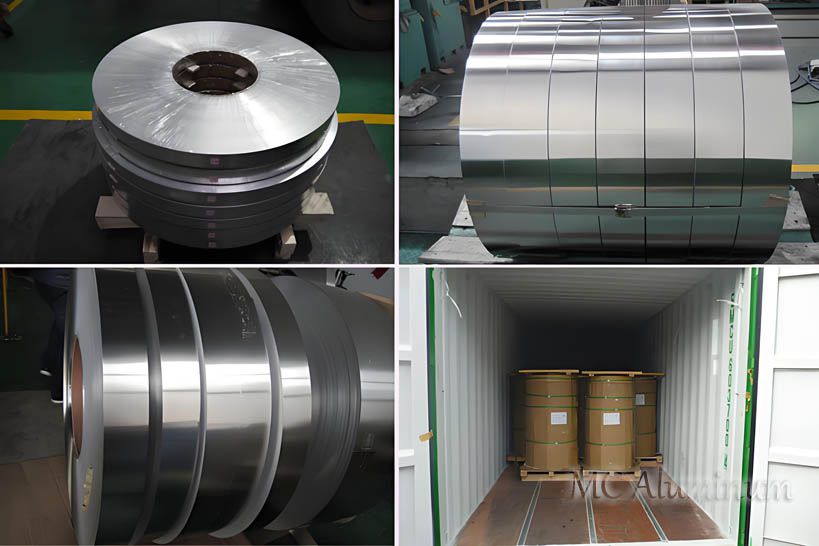

| Packaging | Export-standard wooden cases or pallets |

Advantages of Aluminum Sheet Strip for Automotive Radiators

1.High Thermal Conductivity

Aluminum has a high thermal conductivity, enabling the radiator to efficiently transfer and dissipate heat, improving cooling performance.

2.Lightweight Design

Aluminum has only one-third the density of copper. Using aluminum strips in radiator manufacturing significantly reduces weight, helping lower the overall vehicle weight and enhance fuel efficiency.

3.Corrosion Resistance

Aluminum strips undergo special alloy treatment and surface coating processes, effectively resisting corrosion from coolants and external environments, thus extending radiator lifespan.

4.Excellent Workability

Aluminum strips are easy to process and shape, making them suitable for different radiator structures, such as micro-channel radiators and high-efficiency finned radiators, to meet the requirements of various vehicle models.

5.Cost Efficiency

Aluminum is more cost-effective than copper, and its mature manufacturing processes help reduce production costs and enhance market competitiveness.

Contact Us