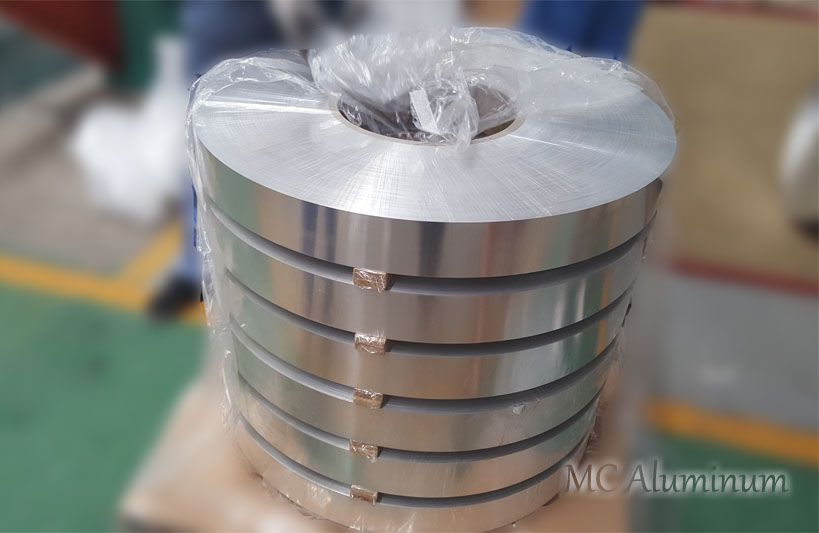

3004 / 3104 series aluminum alloy strips

3004 and 3104 series aluminum alloy strips are important representatives of 3XXX series aluminum-manganese alloys. They are widely used in many fields with excellent mechanical properties, excellent corrosion resistance and good processing and forming properties. These alloy materials not only have the advantages of lightweight, but also have outstanding performance in strength and durability, and are particularly suitable for packaging, construction and industrial purposes.

Features of 3004/3104 series aluminum alloy strips:

Corrosion resistance: Contains manganese, has strong corrosion resistance, and is suitable for humid and chemical environments.

High strength: 3104 has higher strength than 3004, and 3004 is higher than 3003 aluminum alloy, combining strength and ductility.

Excellent forming performance: Easy to perform deep drawing, bending and other processing, suitable for complex shape products.

Lightweight: Low density, high specific strength, in line with modern lightweight design requirements.

Surface quality: The surface is flat and smooth, easy to process later, and takes into account both beauty and functionality.

Processability and weldability: easy to cut and weld, suitable for a variety of processing techniques.

Economical: low material cost, high cost performance, suitable for mass production.

3004/3104 aluminum strip processing technology:

Extrusion: can be processed into various profiles, such as pipes, bars, etc.

Stamping: suitable for making various sheet parts, such as tanks, lids, etc.

Stretching: can stretch sheets or strips into products of the desired shape.

Forging: Although not particularly suitable for forging, forging can also be performed under certain conditions.

Welding: can be welded by argon arc welding, resistance welding, etc.

Surface treatment: can be surface treated by anodizing, painting, etc. to improve its corrosion resistance and aesthetics.

Aluminum strip specifications:

| Alloy | 3004, 3104 |

| Temper | O-H112,H19,H24 |

| Thickness | 0.2-4 mm |

| Width | 6-600 mm |

| Length | 500-13000 mm |

| Processing services | bending, uncoiling, welding, stamping, cutting |

| Surface | grinding, anodizing, embossing, PVC coating, etc. |

| Application | can body materials, thin plate processing parts, building baffles, cable ducts, lampshade materials, various lamp parts, coatings, building materials. |

Chemical composition (%):

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | - | 0.25 | - | 0.05 | 0.15 | remainder |

| 3104 | 0.5 | 0.7 | 0.1 | 0.9-1.5 | 0.3 | - | 0.25 | 0.1 | 0.05 | 0.15 | remainder |

3004 aluminum strip VS 3104 aluminum strip

1. Alloy composition

3004 aluminum strip: The main alloying elements are magnesium and manganese, and the magnesium content is usually 0.81.3%, and the manganese content is 1.01.5%.

3104 aluminum strip: It also uses magnesium and manganese as the main alloying elements, but the magnesium content does not exceed 0.3%, and the manganese content is 0.9~1.5%.

2. Mechanical properties

3004: Slightly lower tensile strength and yield strength, suitable for medium-strength application scenarios.

3104: High tensile strength and yield strength, can meet the application requirements of higher strength and hardness, especially in areas with higher structural stability requirements.

3. Performance characteristics

3004 aluminum strip: has high strength, good corrosion resistance and formability, easy to weld and process.

3104 aluminum strip: has appropriate elongation, good corrosion resistance and processing performance, suitable for a variety of forming processes.

4. Application areas

3004 aluminum strip: widely used in packaging, construction, transportation and home appliances, especially in places requiring high strength and corrosion resistance.

3104 aluminum strip: mainly used to make can covers, aluminum-magnesium-manganese roofs and color-coated sheet roll base materials, etc., and also suitable for some appearance parts and storage tanks, etc.

Why choose MC Aluminum?

1. Good shape flatness, no edge waves or middle waves that affect coating, no warping caused by slitting;

2. Better surface quality, smooth and flat surface, no corrosion spots, wrinkles, non-metallic inclusions, scratches, oil stains, impact or other defects

Contact Us