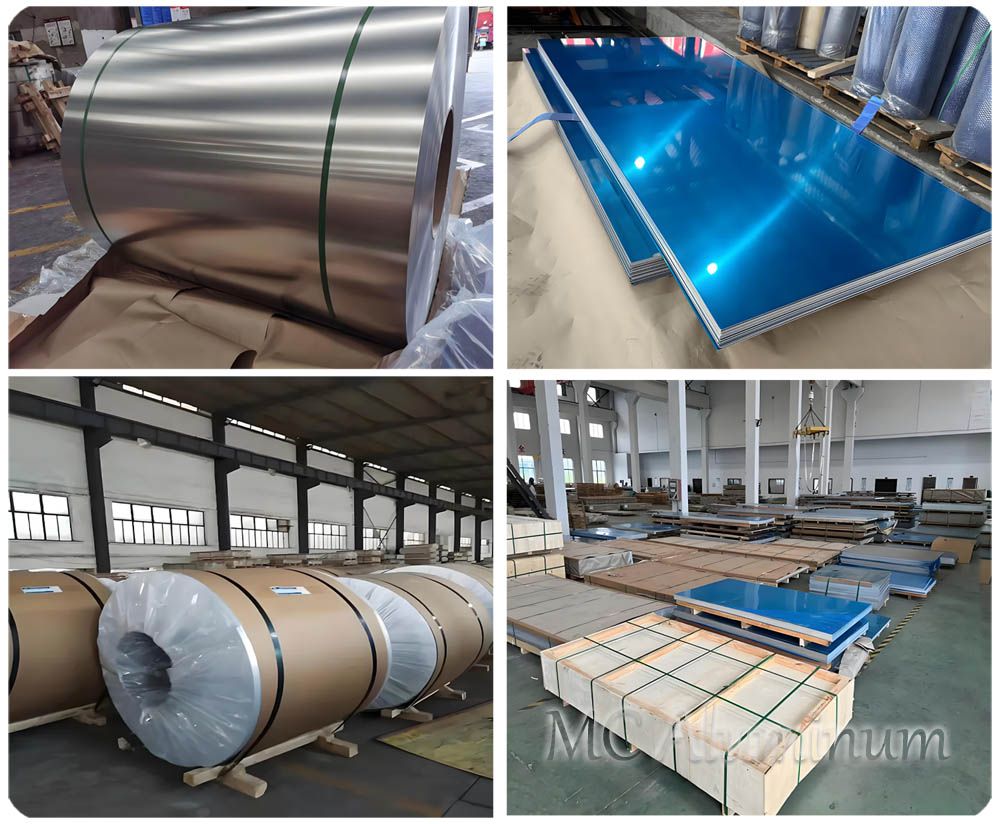

5052-H32 Aluminum Sheets and Coils

5052-H32 aluminum sheets and coils belong to the aluminum-magnesium alloy family, one of the most widely used rust-resistant aluminum alloys today. The designation “5052” refers to the alloy type in the 5xxx series, which offers the highest strength among non-heat-treatable aluminum alloys. Compared with 1100 or 3003 alloys, 5052 has superior fatigue strength. The marine-grade 5052 aluminum plate also exhibits excellent resistance to marine atmosphere and seawater corrosion.

The “H32” temper means the material has been strain-hardened and then stabilized through a low-temperature treatment, ensuring balanced strength and formability. Thanks to its excellent corrosion resistance, moderate strength, and outstanding formability, 5052-H32 is widely used in aerospace, shipbuilding, transportation, construction, home appliances, and other sectors.

Key Properties of 5052-H32 Aluminum Alloy

1.Outstanding Corrosion Resistance

Exceptional resistance to marine and industrial atmospheric environments. Ideal for applications exposed to salt spray, humidity, and harsh conditions.

2.Moderate Strength with High Fatigue Resistance

Its tensile strength is about 210–260 MPa, and its yield strength is about 130–195 MPa. Its strength is better than that of 1xxx and 3xxx series aluminum alloys, and it is stable in load-bearing structures.

3.Excellent Weldability and Workability

Suitable for various welding techniques (e.g., TIG, MIG), with stable weld joint performance. Excels in cold forming processes like bending, stamping, and edge curling.

4.Superior Surface Finish Compatibility

High surface smoothness and excellent for anodizing. Supports decorative treatments such as powder coating, electrophoresis, and color coating.

Specifications for 5052 Aluminum Sheets and Coils

| Thickness | Coils: 0.2 mm – 10 mm |

| Sheets: 1 mm – 100 mm | |

| Width | 1000 mm – 2000 mm |

| Length | 2000 mm – 6000 mm, or custom sizes |

| Surface Options | Brushed, mirror, matte, sandblasted, anodized, color coated |

| Typical Applications | Aircraft parts, household appliances, marine and transportation components, commercial cookware, food processing equipment |

| Minimum Order Quantity | 1–3 tons |

Physical Properties

| Density | 2.68 g/cm³ |

| Melting Point | 607–649°C |

| Thermal Conductivity | 138 W/(m·K) |

| Electrical Conductivity | 35% IACS |

Mechanical properties (H32 state)

| Temper | Ultimate Strength | Yield Strength | Tensile Strength (KSI) | Yield Strength (KSI) |

| O | 195 MPa (28,000 PSI) | 89.6 MPa (13,000 PSI) | - | - |

| H32 | 228 MPa (33,000 PSI) | 193 MPa (28,000 PSI) | 31.0 – 38.0 | >23.0 |

| H34 | 262 MPa (38,000 PSI) | 214 MPa (31,000 PSI) | 34.0 – 41.0 | >26.0 |

| H36 | 276 MPa (40,000 PSI) | 241 MPa (35,000 PSI) | 37.0 – 44.0 | >29.0 |

| H38 | 290 MPa (42,000 PSI) | 255 MPa (37,000 PSI) | >39.0 | >32.0 |

Chemical Composition of 5052 Aluminum Alloy (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | remainder |

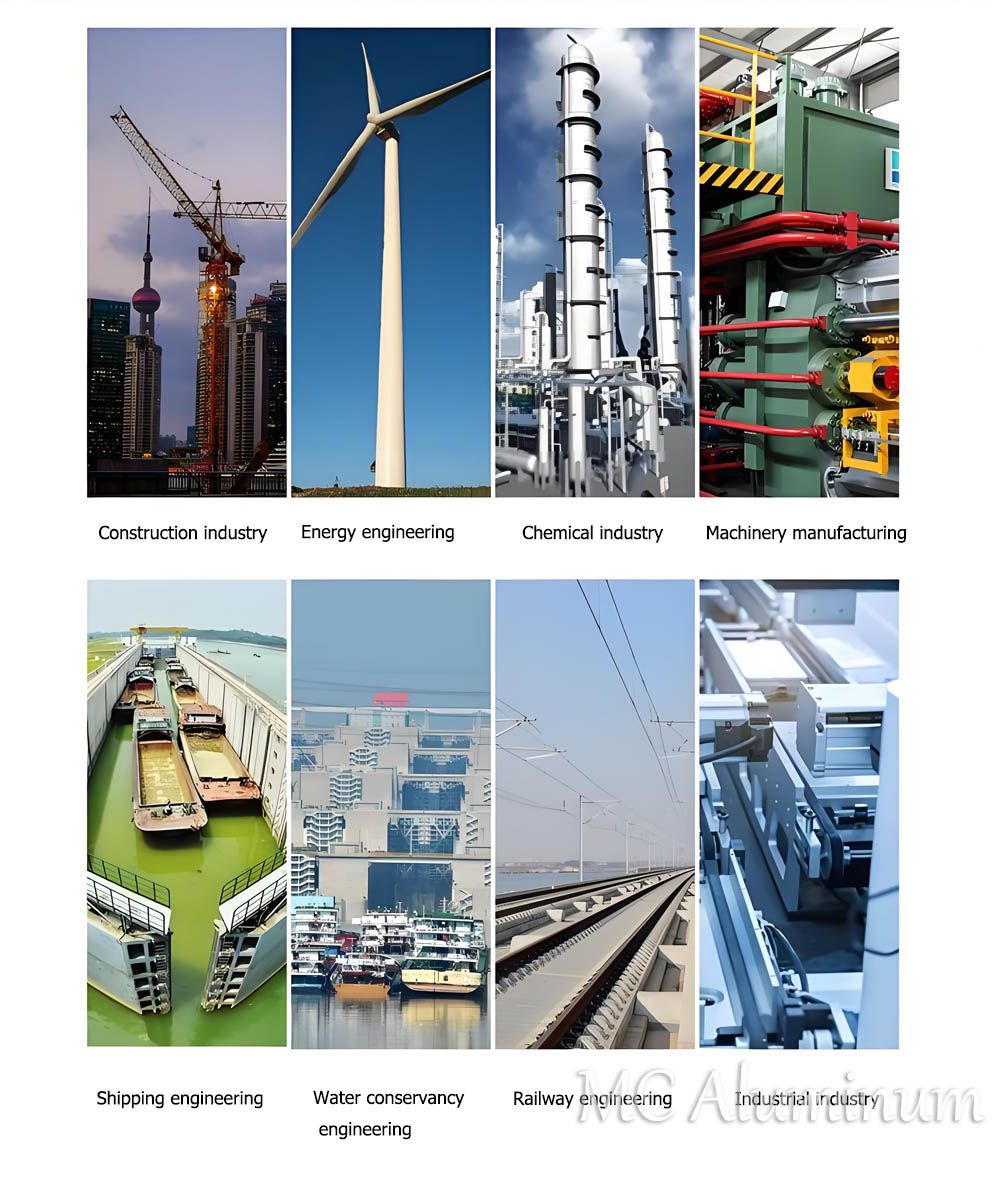

Application Fields

Aerospace

Shipbuilding

Automotive Manufacturing

Architecture & Interior Decoration

Petrochemical Industry

Power & Electrical Equipment

Electronics and Telecommunications

Food and Beverage Packaging

Transportation

Medical Equipment

Comparison with Other Common Aluminum Alloys

| Property | 5052-H32 | 1060-H24 | 3003-H14 | 6061-T6 | 5083-H116 | 7075-T6 |

| Alloy Series | Al-Mg | Pure Al | Al-Mn | Al-Mg-Si | High-Mg | Al-Zn-Mg |

Tensile Strength (MPa) | 210–260 | 75–105 | 140–180 | 260–310 | 275–350 | 520–570 |

Yield Strength (MPa) | 130–195 | 30-50 | 115–145 | 240–270 | 215–300 | 470–505 |

Elongation (%) | 10–20 | ≥25 | 20–30 | 8–12 | 10–20 | 7–11 |

Density (g/cm³) | 2.68 | 2.70 | 2.73 | 2.70 | 2.66 | 2.81 |

Weldability | Excellent | Excellent | Good | Fair | Excellent | Poor |

Corrosion Resistance | Excellent | Fair | Good | Good | Excellent (Marine Grade) | Poor |

Formability | Good | Excellent | Excellent | Excellent | Moderate | Poor |

Heat-Treatable | No | No | No | Yes | No | Yes |

Selection Recommendations

For extreme corrosion resistance (e.g., deep-sea environments) → Choose 5083-H116 marine aluminum plate

For high structural strength (e.g., aerospace applications) → Choose 6061-T6 or 7075-T6

For cost-effective and easy forming needs (e.g., household goods) → Choose 3003-H14

For balanced performance across corrosion resistance, strength, and formability → 5052-H32 is your go-to universal choice, especially suited for automotive, chemical, and marine industries.

Contact Us