5083 LNG storage tank aluminum plate

Liquefied natural gas storage tanks are professional products for storing liquefied natural gas, special equipment, and three types of pressure vessels. Liquefied gas storage tanks have strict quality appraisal on the material of pressure components, appearance size, weld quality, operation quality, installation quality, internal devices and safety accessories.

Liquefied natural gas has special physical and chemical properties, and it needs to be stored in an environment below -160°C, which has high requirements for the insulation and airtightness of the container. The tank wall material inside the tank should have sufficient low temperature resistance, so the selection of insulation materials for LNG storage tanks is also particularly important. The 5083 aluminum plate has excellent characteristics and meets the processing needs of LNG storage tanks, and is widely used by many companies.

5083 aluminum plate belongs to aluminum-magnesium alloy, which has good corrosion resistance and processability, high strength, excellent formability, and easy surface treatment. 5083 aluminum alloy has no low temperature brittleness, its mechanical properties do not decrease with the drop of temperature, and it can still maintain high strength at low temperature. At the same time, the economy of aluminum alloy is relatively good, so it is widely used in LNG ships and LNG storage tanks.

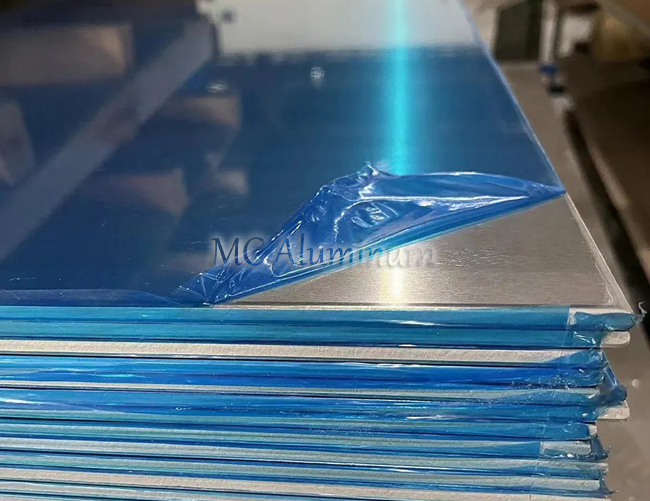

5083 aluminum plate technical parameters

Material status: F.O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H111, H112, H114, H116, H321

Thickness (mm): 0.5-500

Width (mm): 20-2650

Length (mm): 500-16000

Application: ship deck, LNG storage tank, gas storage tank, GIS shell, car body skin, flange material, etc.

MC Aluminum is one of the relatively powerful aluminum plate manufacturers, specializing in the production of high-quality 5083 aluminum plates for the construction of LNG storage tanks, strictly controlling the product process of 5083 aluminum plates, through determination of alloy composition, optimization of melting and casting process, homogenization heat treatment and rolling The process test shows that the product has excellent performance, meets the requirements of many industries, and has broad application prospects.

Contact Us