5456 Marine Aluminum Alloy with DNV Certificate

5456 aluminum alloy is a high-strength aluminum-magnesium alloy with excellent mechanical properties, corrosion resistance and weldability. It is widely used in ship structural parts, hull plates and other marine equipment due to its excellent seawater corrosion resistance and high strength.

5456 marine aluminum plate is mainly used for structural applications. Like most aluminum-magnesium alloys, it is not usually used as a welding filler. The material can be cold-worked to increase strength, but the ductility will be reduced. It should be noted that exfoliation corrosion is prone to occur when exposed to an environment above 65°C (150°F) for a long time.

The performance of 5456 marine aluminum plate is similar to that of 5083 aluminum alloy and 5086 aluminum alloy, but it has slightly higher strength, good machinability and weldability, and has a certain stress corrosion sensitivity, and cannot be strengthened by heat treatment. This aluminum plate is widely used in the deck and other parts of ships due to its excellent performance. According to different alloy states, 5456 marine grade aluminum plates are usually used for bulkheads and superstructures, patrol boats and workboat hulls, shipyard plates and plates.

Product specifications:

| Alloy | 5456 |

| Temper | O, H111, H112, H321, H24, H32, H34, H36, H38, etc |

| Size | T (3-50) XW (1000-2650) X (1000-16000) mm |

| Certificate | BV /DNV /ABS/Lioyds |

| Use | Aluminum is the preferred material for designers of high-speed ships such as high-speed ferries, LNG spherical tanks, hydrofoils, offshore workboats, yachts, etc., and is widely used in shipboards, bottom plates, portholes, carrier plates, side plates of ship containers, etc. |

| Product features | long width, corrosion resistance, small elastic modulus, easy welding, easy processing, no low-temperature brittleness, and non-magnetic. |

5456 chemical composition (%):

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 5454 | 0.4 | 0.4 | 0.1 | 0.4-10. | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | 0.05 | 0.15 | Remainder |

Characteristics of 5456 marine grade aluminum plate:

Compared with traditional steel, 5456 marine aluminum plate has the following advantages:

1.Reduce hull weight: The density of aluminum alloy is lower than that of steel. The use of 5456 aluminum plate can significantly reduce the weight of the hull and improve the ship's load-bearing capacity and stability.

2.Increase speed: Lightweight hull can reduce the resistance of the ship, increase the speed, and shorten the sailing time.

3.Reduce fuel consumption: Reducing the weight of the hull can reduce the fuel consumption of the ship and save operating costs.

4.Reduce maintenance costs: 5456 aluminum plate has good corrosion resistance, which can reduce the maintenance and maintenance costs of the ship.

Application areas:

1.Ship structures: hulls, decks, bulkheads and other structural parts

2.Marine engineering: offshore drilling platforms, submarine pipelines, floating facilities, etc.

3.Military industry: warships, ship armor plates

4.Other applications with high corrosion resistance requirements: storage tanks, chemical equipment, pressure vessels, etc.

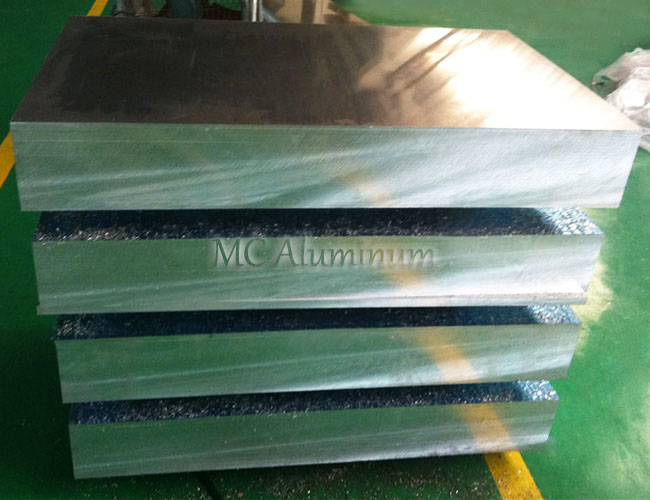

Quality requirements for 5456 aluminum plates for shipbuilding:

1. Dimension tolerance:

Thickness tolerance +/-1.5%, width tolerance +/-1mm

2. Surface quality:

The surface of the aluminum plate is free of oil stains, dents, inclusions, scratches, stains, oxidation discoloration, fractures, corrosion, roller marks, dirt streaks and other defects that affect use.

3. Mechanical properties:

Chemical compound and mechanical properties can meet the requirements of GB/T, ASTM, ENAW, JIS standards

MC Aluminum produces marine aluminum plates mainly based on 5-series and 6-series aluminum alloys, represented by 5083 aluminum plates, including 5083, 5086, 5052, 5383, 5454, 5456, 5754, 6061, 6063 and other aluminum grades. The product models are complete, exported to many countries overseas, factory direct sales, preferential prices, can undertake 1-2000 tons of orders, professional after-sales service.

Contact Us