8011 aluminum foil is widely used in capsule aluminum foil board

At present, capsule aluminum foil board is more and more commonly used in the form of blister packaging, which is also called blister packaging, referred to as PTP. Almost all products in modern packaging that require opaque or high-barrier composite materials use aluminum foil as a barrier layer. This is because aluminum foil has a highly dense metal crystal structure and can completely block any gas, so it is widely used.

8011 aluminum foil is widely used in the pharmaceutical industry due to its good barrier properties, mechanical strength and formability, especially aluminum foil for capsule packaging (also known as capsule aluminum foil board). This kind of aluminum foil can effectively protect drugs and prevent moisture, oxygen, light, etc. from affecting the quality of drugs.

Introduction to 8011 aluminum foil material:

8011 aluminum foil is mainly composed of aluminum (Al) and contains a small amount of copper (Cu), manganese (Mn), magnesium (Mg), silicon (Si) and other elements. The addition of this alloy element improves the strength and tear resistance of aluminum foil, making it more suitable for pharmaceutical packaging.

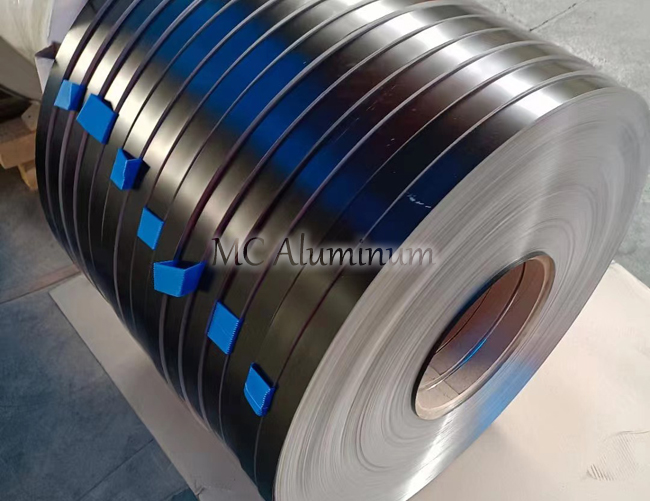

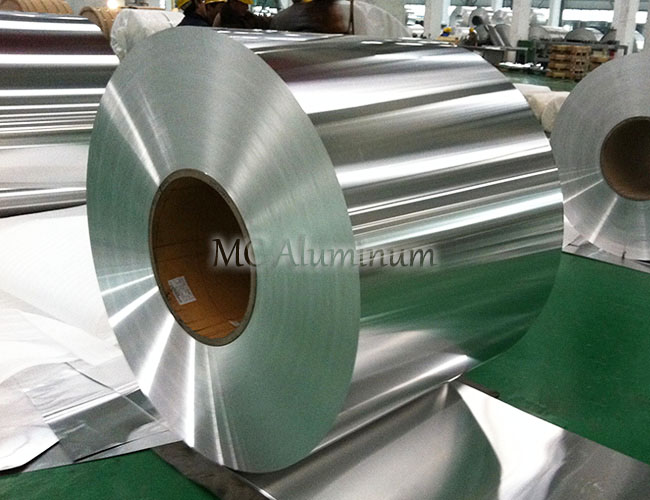

The common thickness of 8011 aluminum foil used for pharmaceutical packaging materials is 0.02mm - 0.04mm, and the width is usually between 100 - 500mm. Capsule aluminum foil sheets are generally designed to customize thickness and width according to the specific needs of pharmaceutical packaging in order to adapt to different capsule sizes and packaging requirements.

Structure of capsule aluminum foil sheet

Capsule aluminum foil sheet is usually composed of aluminum foil layer and other composite layers, and the structure is as follows:

Aluminum foil layer: 8011 aluminum foil is used as the main barrier layer to play an airtight protection role.

Adhesive layer: used to connect the aluminum foil layer and the plastic layer to ensure the firmness of the structure.

Plastic layer (such as PVCor PE): provides flexibility for packaging and improves the impact resistance of aluminum foil, which helps to form a good molding effect.

Advantages of 8011 aluminum foil in capsule aluminum foil sheet:

1.Excellent barrier properties: effectively prevent drugs from reacting with oxygen and water vapor, and extend the shelf life.

2.Good sealing: compounded with other materials to form a tightly closed structure to prevent leakage and contamination.

3.Easy to process: has good ductility and plasticity to meet different packaging needs.

4.Beautiful: enhance the grade and attractiveness of packaging after printing.

5.Easy to tear: capsule aluminum foil is designed to be easy to peel off, which is convenient for patients to use.

8011 aluminum foil is mainly used in the packaging of various pharmaceutical products, including:

Capsule packaging: such as capsule drugs such as vitamins and antibiotics.

Tablet packaging: used for some tablets that are sensitive to light and moisture.

Powder packaging: drug packaging for certain medical powders and oral dosage forms to prevent drugs from absorbing moisture and agglomerating, etc.

8011 aluminum foil surface quality:

8011 aluminum foil surface is flat and smooth, without obvious defects such as cracks, bubbles, inclusions, etc.

Its surface can also be processed in various ways, such as printing, coating, etc., to meet different application requirements.

MC Aluminum is a manufacturer of aluminum foil raw materials for pharmaceutical packaging. It can accept orders for 3-2000 tons of aluminum foil raw materials. Its product quality is stable, exported globally, and its price is affordable. It is a supplier of aluminum foil raw materials for pharmaceutical packaging for various domestic and foreign pharmaceutical packaging companies.

Contact Us