8011 H18 O Aluminum foil for capsule medicine plate

Medicinal aluminum foil is used to package pharmaceutical tablets, capsules, pills, lozenges, and small foods and candies. At present, the use of blister packaging for capsule aluminum foil plates is becoming more and more common. Aluminum-plastic blister packaging is also called blister packaging, referred to as PTP. The capsule medicine plate uses 8011 aluminum foil as a barrier layer to achieve the effect of shading, blocking moisture, bacteria, mold, and oxygen, and ensuring the quality and effect of the medicine.

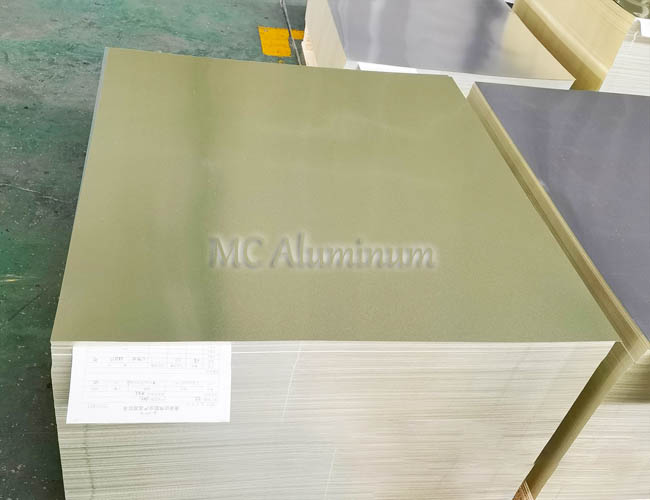

As a professional supplier of raw materials for medical aluminum foil, MC Aluminum produces 8011 and 8021 aluminum foils with smooth surface, clean degreasing, high convexity, high heat sealing strength and good sealing. 8011H18/O aluminum foil is used for flat laying with a thickness of 0.016-0.04mm; 8021-O aluminum foil is used for deep drawing with a thickness of 0.04-0.065mm. Usually used in combination with PVC, PVDC and other materials.

PTP aluminum foil specifications:

| Alloy | 8011 8021 |

| Temper | O, H14, H16, H18 |

| Thickness | 0.016-0.5mm |

| Width | 100-1600mm |

| Length | 100-16000mm |

| Inner diameter | 76cm, 152cm, etc. |

| Core material | paper, iron, aluminum |

| Application | capsule medicine board, candy blister packaging board, tablet medicine board, etc. |

| 8011 aluminum foil chemical composition (mass fraction)/% | |||||||||||

| Alloy | Si | Cr | Cu | Mn | Fe | Zn | Mg | Ti | Other | Al | |

| Single | Total | ||||||||||

| 8011 | 0.5~0.9 | ≤0.05 | ≤0.01 | ≤0.02 | 0.6~1.0 | ≤0.10 | ≤0.05 | ≤0.08 | 0.05 | 0.15 | remaind |

Aluminum-plastic blister performance advantages:

1. Excellent barrier properties, effectively blocking air, moisture and light, ensuring the quality of capsule medicines.

2. Good ductility and toughness, can be processed into various styles of packaging.

3. Can be heat-sealed with a variety of materials (such as PVC, PET, etc.) to prevent packaging leakage.

4. Non-toxic and tasteless, safe and hygienic

5. Corrosion-resistant, dustproof and waterproof

PTP aluminum foil processing requirements:

The layout is flat; the layout requirements are strict, without black oil spots, scratches, small black silk, bright lines, roller-printed concave and convex points, mosquitoes and other phenomena; holes, found to be abolished; trimming quality, no burrs, towers, layer channeling, lotus leaf edges, flanging, concave and convex lighting phenomena; water brushing reaches A-level standards; packaging is moisture-proof and avoids oxidation.

Contact Us