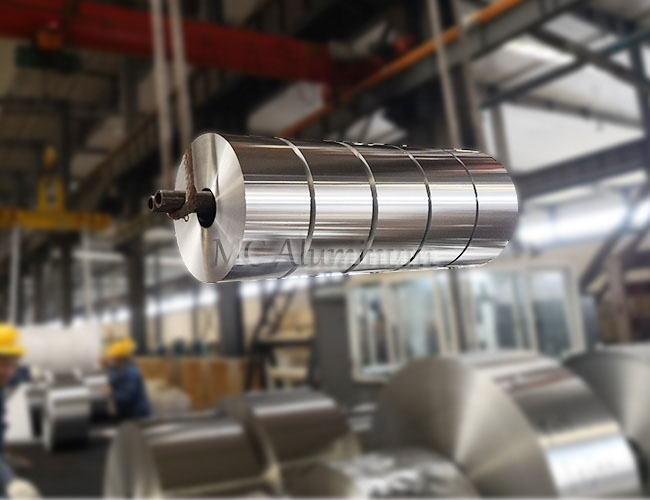

Aluminium closure sheet for ROPP cover

The greatest qualities of aluminium closure sheets are stretchability and paint adhesion, guaranteeing the highest quality printing of drawings and designs that can achieve various painted finishes on their market. The most commonly used alloy for aluminum closure plates for ROPP caps is 8011 alloy, which has good formability, good ear forming rate and flatness to ensure the deep drawing of long bottle caps. It usually uses ROPP caps such as bottle caps, aluminum liquid caps, red wine caps, anti-theft caps, perfume caps, skin care product caps, cosmetic caps, oil caps, aluminum caps, oral liquid plastic composite caps, infusion bottle aluminum plastic caps, etc.

Basic information of aluminium closure plates for ROPP cover:

| Alloy | 1060、3003、3105、5052、8011,etc |

| Temper | H18、H19、H22、H24、H26、H14、H16 |

| Thickness | 0.15~0.5mm |

| Width | 500~2500mm |

| Length | 600mm~1000mm |

| Rolling process | CC/DC |

| Surface treatment | rolled surface |

| Surface type | |

1. Smooth polished aluminum strip 2. DOS oil lubrication surface treatment 3. Chromate surface treatment 4. One side is gold/white/red/blue/black and other colors, and the other side is protective paint 5. Double-sided transparent/transparent paint | |

| Test items | high pressure sterilization test, Hgcl2 test; |

| Tensile strength | 130-155mpa; |

| Elongation | 2.5-3.5%; |

| Ear cutting rate | maximum 2%; |

Advantages of aluminum closure plate for ROPP cover:

1. First-class formability, flatness, rectangularity and stable surface properties.

2. Stable drawing quality ensures the highest material utilization rate.

3. A variety of processes and technologies can meet the requirements of various surfaces.

4. Anti-theft turned on.

Contact Us