Non-stick pan with 3003 aluminum circles, affordable.

There are many pot products on the market, mainly stainless steel pots, iron enamel pots, iron pots and non-stick pots. Each of these pans has its pros and cons, with non-stick pans being the most prominent. Non-stick pans are similar in appearance to ordinary pans, but the interior of the non-stick pan is coated with a layer of polytetrafluoroethylene. The excellent thermal properties, chemical properties and easy cleaning properties of polytetrafluoroethylene are used to make this popular kitchen utensils.

Non-stick pans are easy to clean and clean with a single wipe. It can be said that it overcomes almost all the shortcomings of traditional pans. We need to cook and eat every day, and the quality of the pot directly affects our daily life. As the name suggests, a non-stick pan is able to not stick to the bottom when frying or frying food, and at the same time minimize the use of oil, reduce oil fumes, and bring convenience to kitchen cleaning. It can also help reduce the intake of fat, which conforms to the trend of modern people's pursuit of low-fat and low-calorie consumption. One of the important points is that non-stick pans are not harmful to the human body.

The 3003 aluminum plate raw material for non-stick pans has many advantages. The density of aluminum alloy is about one-third of that of steel. The use of aluminum alloy makes the pot lighter; aluminum has strong electrical conductivity, and the heat transfer effect of aluminum pot is higher than that of stainless steel pot. multiple times.

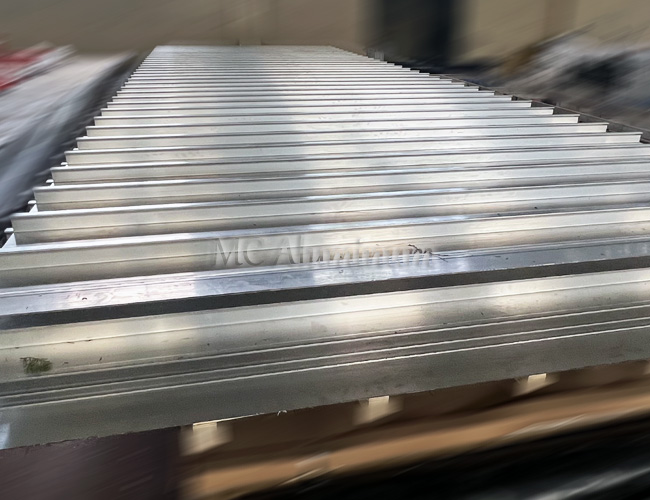

3003 aluminum wafer produced by MC Aluminum Company is an aluminum alloy material that meets the performance requirements of non-stick pan, and 3003 aluminum wafer is a typical Al-Mn alloy, which has good formability, excellent corrosion resistance and weldability. The non-stick coating in the non-stick pan produced by it is smooth, the color, hiding power and luster should be basically uniform, without bubbles and falling off, and the coating is completely hot-melted, without obvious defects such as dirt, cracks and explosion points. This is because 3003 aluminum wafer has the following performance advantages:

1. Strong anti-rust properties.

2. Smooth surface, good plasticity and pressure resistance;

3. Excellent forming and processing characteristics, high corrosion resistance, excellent weldability and electrical conductivity, and the strength is higher than 1100.

3003 Aluminum cirlces Specifications

| Alloy | 3003 |

| Temper | H18,H14,H16,H22,H24,H26 |

| Thickness | 0.2~5mm |

| Diameter | 150~1300mm |

| Application | The product is widely used in Reflector, Traffic sign. Deeply drawing for making cookware, cooking-utensil, non-stick pans/pots, and kitchens. |

How much is a ton of 3003 aluminum circles?

The price of aluminum circles consists of the price of aluminum ingots and processing fees. Generally, the price of aluminum circles from the manufacturers of aluminum circles is based on the price of Changjiang aluminum ingots on the day of delivery. Different specifications have different processing fees. When users make an inquiry, if they want a more accurate quotation, they need to provide the specific model, state, thickness, width and length of the required product, which is convenient for manufacturers to calculate. MC Aluminum specializes in the production of various specifications of aluminum sheets, aluminum coils, aluminum circles and other aluminum products, welcome to order!

Contact Us