Aluminum alloy tank car raw material supplier

Aluminum is the earliest lightweight metal material used in automobile manufacturing. It is also the most economical, practical and competitive structural material. The specific gravity of aluminum is about 1/3 of steel. Aluminum alloy is recognized as an ideal material for automobile lightweight. In Europe and North America, aluminum alloys are widely used in the automotive industry, especially for heavy-duty and special-purpose vehicles, in order to achieve lightweight vehicles. The aluminum industry has developed a variety of aluminum alloy materials for van trucks, semi-trailers, dump trucks, tank trucks, etc. The wide application of aluminum alloys in commercial vehicles, especially in tank trucks, has accelerated The next generation of commercial vehicles in Europe and North America. Except for a very small number of transporting special chemicals, almost all tanks in Europe and the United States are made of aluminum alloy, with a market share of more than 90%.

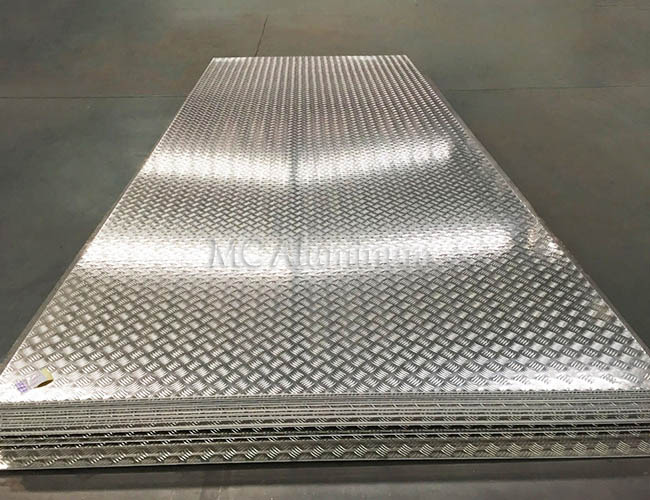

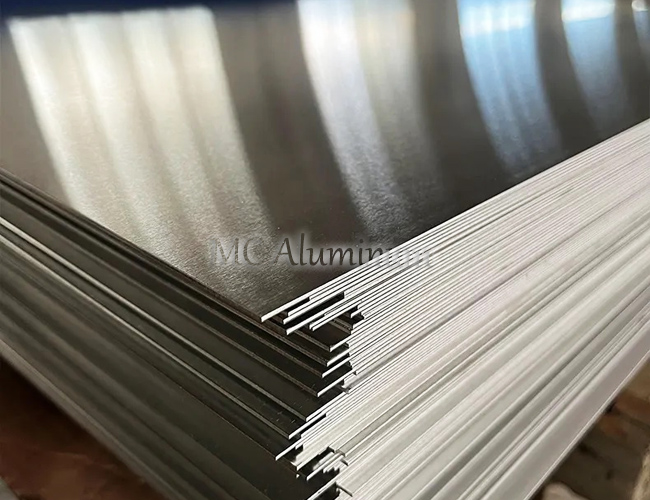

Aluminum alloy tank trucks mainly use 5454 aluminum plates, 5182 aluminum plates, and 5083 aluminum plates. A complete tanker body generally needs 4-6 aluminum plates to be welded together. The most important tank body is made of 5083H111 aluminum plate, and the tank lids on both sides are made of 5083-O aluminum plate, which is softer. The can lids on both sides need to be bent, and the partition part is also in the 5083-O state. In addition, some manufacturers use 5454H111 aluminum plates to produce tanks. The tank car partition can be made of 5182 aluminum plate.

Aluminum plate manufacturers introduce the comprehensive advantages of aluminum alloy tank cars

1. High security. Safety is an important indicator for considering tank trucks. Due to the low weight of the aluminum alloy tank truck, the center of gravity is low, it is not easy to roll over, and it is safer.

2. Light weight, high payload. Since aluminum alloy tank trucks are lighter in weight than carbon steel tank trucks, fuel consumption and tire wear during transportation are reduced, thereby reducing daily operating and maintenance costs.

3. Good corrosion resistance, long service life and strong corrosion resistance. 15-20 years is the typical service life of an aluminum alloy tank car. A layer of dense aluminum oxide will be formed on the surface of the aluminum tank car, which can effectively prevent the erosion of the atmosphere and moisture, and the oil tank car will not pollute the oil due to rust. No need to paint and apply any protective layer, saving maintenance costs.

4. The product has excellent performance and beautiful appearance. The tank body is made of aluminum alloy, which has good elongation and high strength; the aluminum tank car can greatly reduce the weight, and the economic benefits of saving fuel during the entire service life are very considerable.

5. Better fuel efficiency, less environmental pollution, more green and environmentally friendly, in line with national energy conservation and emission reduction policies.

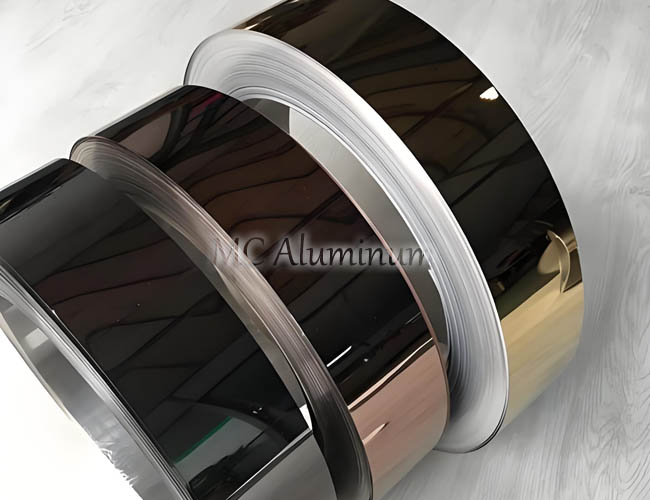

MC Aluminum is a large-scale manufacturer of aluminum sheets, which can produce 1-8 series aluminum sheets. The product models are complete, the production technology is skilled, the technical equipment is advanced, the product quality is high-quality, and it is exported worldwide. Users can rest assured to order!

Contact Us