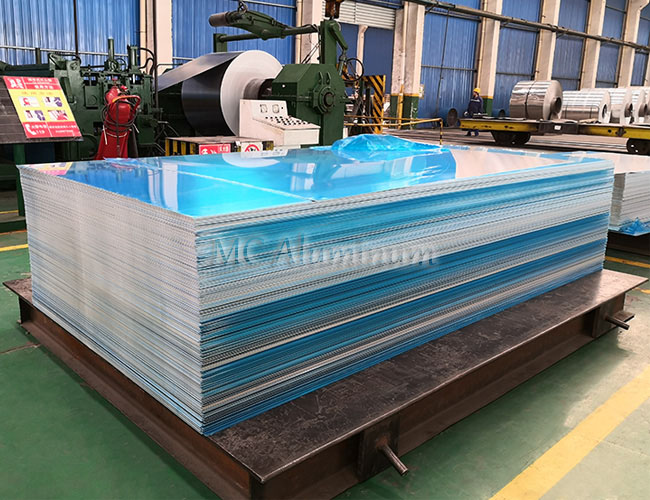

1050 1060 aluminum plate is suitable for CTP/PS plate base

PS/CTP plates can be collectively referred to as printing plates or offset plates. They are plates with a photosensitive layer coated on an aluminum substrate and can be printed on the machine after plate making. The substrates of modern printing plates are all aluminum plates. The aluminum plate base is 1050, 1060, 1050A, etc. The state is mainly H18, with a width of 0.15mm, 0.2mm, 0.25mm, 0.3mm, 0.35mm, 0.4mm, etc., which can be customized according to customer needs.

CTP/PS plate base material characteristics:

1050 aluminum plate:

The aluminum content reaches 99.5%.

It has good toughness, ductility and weldability.

Low cost and easy processing.

The tensile strength (normal temperature) is between 185~215MPa, and the tensile strength after baking is 125~140MPa.

The elongation after fracture is greater than 1%.

1060 aluminum plate:

The aluminum content reaches 99.6%.

It is slightly higher than 1050 aluminum plate in hardness and strength, but still maintains a softer property.

The surface is smooth and easy to print.

The tensile strength (normal temperature) is between 200~230MPa.

It also has an elongation after fracture greater than 1%.

1 Series Aluminum Plate Specifications:

| Alloy | 1050, 1060, 1050A |

| Temper | H18 |

| Thickness | 0.1-0.5mm |

| Width | 100-1600mm |

| Length | 100-16000mm |

1050/1060 Aluminum Plate for CTP/PS Plate Features:

1. Excellent formability

2. Corrosion resistance, moderate wear resistance

3. Excellent hydrophilicity

4. Surface finish

5. Low cost

6. High flatness

PS/CTP Plate Application:

Widely used in positive PS plate, thermal CTP plate, photosensitive CTP plate, UV-CTP plate and other offset printing plates

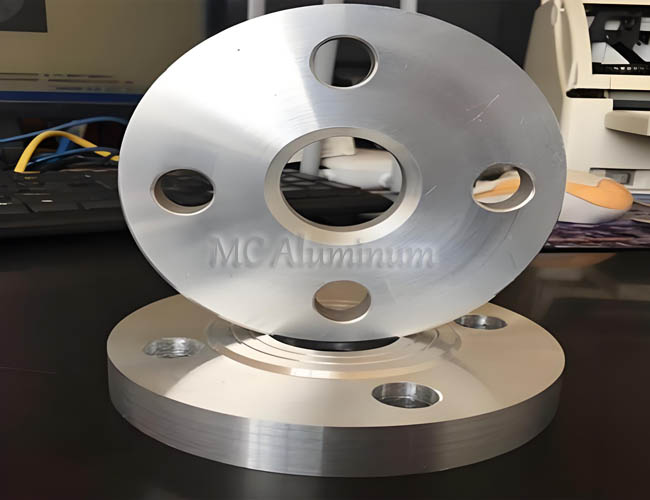

MC Aluminum specializes in the production of aluminum plates for PS/CTP plate. The products have good toughness, ductility, flatness, hardness and strength, and are the most ideal materials for producing PS/CTP plate. Factory direct sales, fast delivery, preferential prices, global exports.

Contact Us