Aluminum foil tape 1235 aluminum foil, 8011 aluminum foil _ aluminum foil manufacturer

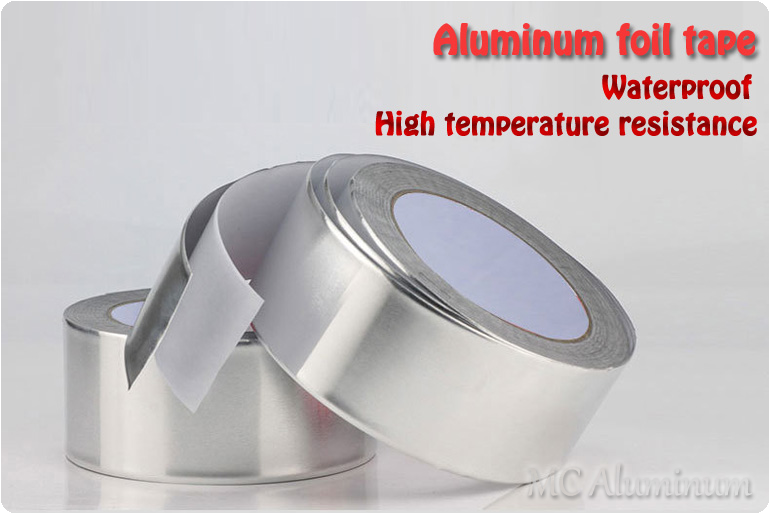

Tape aluminum foil is a composite material with glass fiber reinforcement between aluminum foil and kraft paper. It has the characteristics of flame retardant, waterproof, high energy saving, etc., and it is cheap, easy to construct and durable. It is a new generation of thermal insulation, heat insulation and sound insulation. It is an ideal supporting layer for building materials and other building materials. Tape aluminum foil is made of aluminum foil substrate. Common alloys in the market include 8011 aluminum foil and 1235 aluminum foil, which can be subdivided into soft and hard states (ie, H18 and O states), single-sided light and double-sided light. According to different performance requirements, the production process is also different.

The alloy composition of 1235 aluminum foil used for tape aluminum foil is different from that of 8011 aluminum foil. The difference in process lies in the different annealing temperature. The annealing temperature of 1235 aluminum foil is lower than that of 8011 aluminum foil, but the annealing time is basically the same. The difference between the finished aluminum foil tape 1235 aluminum foil and 8011 aluminum foil is that the strength is slightly different. The tensile strength of 8011 aluminum foil is higher than that of 1235 aluminum foil. At the same time, the elongation of 8011 aluminum foil is not much different from that of 1235 aluminum foil, slightly higher.

The main process procedures of aluminum foil tape are blank opening, aluminum foil rolling mill cold rolling, upper slitting machine for slitting, cleaning, annealing (selected according to performance requirements), and packaging. The entire production cycle is about 10 days.

Tape aluminum foil is suitable for all kinds of transformers, mobile phones, computers, PDAs, PDPs, LCD monitors, notebook computers, copiers and other electronic products where electromagnetic shielding is required.

Specifications of 1235 aluminum foil and 8011 aluminum foil for aluminum foil tape

| Alloy | 1235,8011 |

| Temper | O,H18 |

| Thickness | 0.008~0.025mm |

| Width | 100~1220mm |

| Coil ID | 75, 150 |

Advantages of 1235 aluminum foil and 8011 aluminum foil for aluminum foil tape

1.The surface of the aluminum foil is uniform in color, clean, and flat, without obvious roll marks, pits, pinholes, and corrosion marks.

2.The surface of aluminum foil has no rolling defects such as creases, mottles, bright lines, etc.

3.No color difference on the surface of aluminum foil.

4.No oil on the surface, no serious oil odor, no visible oil spots.

Contact Us