Aluminum Strip Standard for Dry-Type Transformers

Aluminum strip for dry-type transformers is a strip obtained by melting, rolling and slitting aluminum ingots, and is mainly used to manufacture windings for dry-type transformers. A dry-type transformer refers to a transformer whose core and winding are not immersed in insulating oil, and whose windings are usually made of aluminum strips or aluminum foil.

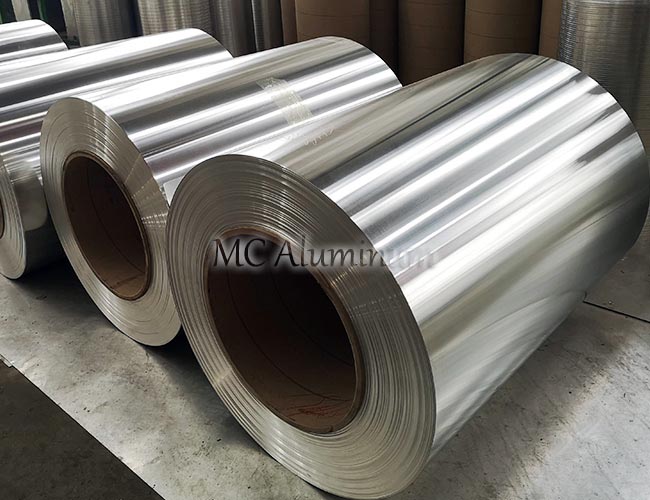

MC Aluminum provides 1060 aluminum strips, 1050 aluminum strips, 1050A aluminum strips, 1350 aluminum strips, etc. for dry-type transformers, and the state is usually O state (soft state). The thickness of the aluminum strips for dry-type transformers that can be provided is usually between 0.08-3.00mm, and the width can be customized according to demand. Common thickness specifications are 0.2mm-3.0mm, and width specifications are 20mm-1650mm, etc.

The aluminum strip materials used in dry-type transformers need to meet certain standards to ensure their conductivity, mechanical properties and durability. Commonly used aluminum strip standards include the following:

1. Resistivity: At 20°C, the resistivity should be ≤0.0282Ω·mm²/m, in line with the national standard GB/T 3955.

2. Mechanical properties: such as tensile strength, yield strength and elongation must comply with the national standard GB/T 3880 to avoid breakage or deformation during use.

3. Insulation performance: Aluminum strips require additional insulation layers, commonly used materials are glass fiber or polyester film, and must comply with IEC 60695 and GB/T 5139 standards.

4. Surface quality: The surface should be flat, free of burrs, obvious scratches, oil spots, cracks, cracked edges, bubbles, holes and oxides.

5. Side bending and curvature: The side bending and curvature of the aluminum strip at any length must comply with relevant standards to ensure the neatness and stability of the winding.

The main advantages of aluminum strips for dry-type transformers:

1. Lower cost: The price of aluminum is lower than that of copper, which can effectively reduce manufacturing costs.

2. Lightweight: The density of aluminum is about one-third of that of copper, which reduces the weight of the equipment and facilitates installation and transportation.

3. Stable conductivity: By increasing the cross-sectional area, the aluminum strip can meet the conductivity requirements and ensure long-term stable operation.

4. Strong corrosion resistance: The oxide film on the surface of aluminum improves corrosion resistance and is suitable for use in humid environments.

5. Good plasticity: The aluminum strip has strong ductility, is easy to process, and improves production efficiency.

6. Energy saving and environmental protection: The recycling rate of aluminum is high, and the production energy consumption is low, which is in line with the trend of sustainable development.

7. Easy to maintain: The aluminum strip winding is not easily affected by moisture and pollution, reducing the risk of failure caused by improper maintenance.

Dry-type transformers are widely used in high-rise buildings, airports, docks, CNC machinery and equipment, as well as in local lighting, power distribution and other fields. As an important component of dry-type transformers, the quality and performance of aluminum strips directly affect the overall performance and service life of the transformer.

MC Aluminum is a professional aluminum sheet, strip and foil manufacturer, specializing in the production of transformer aluminum strips, with a complete range of product models, stable quality, factory direct sales, preferential prices, and exports to many countries and regions overseas, and is highly trusted by customers.

Contact Us