Automotive lightweight aluminum profiles

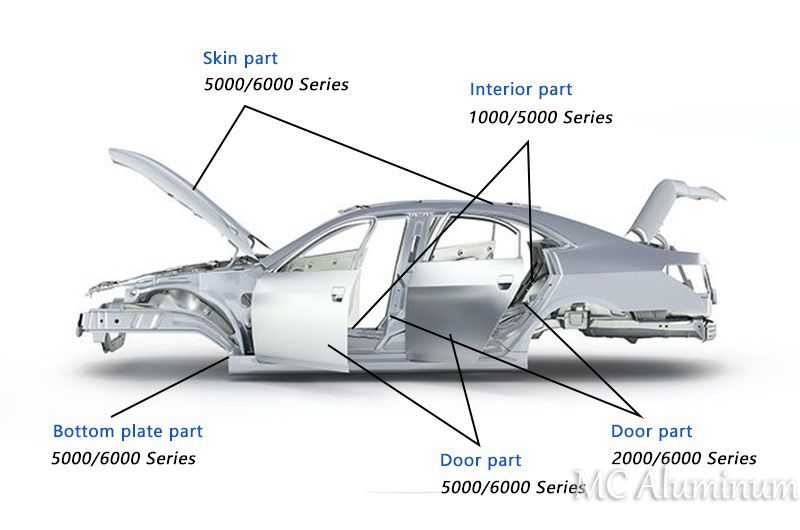

Automotive aluminum profiles are a type of aluminum alloy material specifically used for automobile manufacturing. They are widely used in car bodies, chassis and parts due to their light weight, high strength and corrosion resistance. The use of aluminum profiles helps reduce vehicle weight, improve fuel efficiency, and enhance collision safety.

Aluminum extrusions are used in automobiles to achieve the effect of lightweighting the car by taking advantage of the high strength and light weight of the material. Many models with all-aluminum bodies use a large number of aluminum profiles as the main structural parts to achieve lightweighting of the car.

Automotive aluminum alloy materials:

1. 6 series aluminum alloys: such as 6061 and 6063. These alloys have good strength, weldability and corrosion resistance, and are often used in body structures, doors, roofs and chassis.

2. 7 series aluminum alloys: such as 7075. These alloys have extremely high strength and rigidity and are widely used in the manufacture of suspension systems, wheels and other parts of high-performance cars that need to withstand large loads.

3. 5 series aluminum alloys: such as 5083 and 5754. These alloys have good corrosion resistance and plasticity, and are often used to manufacture automotive fuel tanks, hydraulic oil tanks and other parts that require corrosion resistance.

4. 2 series aluminum alloys: such as 2024. These alloys have good strength and fatigue properties and are often used to manufacture structural components in applications such as aircraft and racing cars.

Features of aluminum profiles for automobiles:

1. Lightweight and high strength: The density of aluminum alloys is only half that of steel, with high strength and hardness, which reduces the weight of the car and improves fuel efficiency and performance.

2. Strong corrosion resistance: It has excellent corrosion resistance, can resist oxidation, corrosion and vibration, and extend the service life of the car.

3. Good formability: It is easy to process into various shapes to meet the needs of different parts, and designers can freely design complex shapes.

4. Excellent heat dissipation performance: Aluminum has good thermal conductivity and is suitable for heat dissipation components (such as electric vehicle battery cooling systems and radiators), which helps thermal management and extends the life of key components.

5. Good energy absorption: Aluminum can effectively absorb and disperse energy during collision, improving the passive safety performance of the vehicle.

6. High recycling rate: It can be recycled through smelting, reducing resource waste and environmental pollution, which is in line with the concept of sustainable development.

Contact Us