Industrial pure aluminum plate/sheet 1050 1060 1070 1100

Aluminum sheets whose purity can reach over 99.00% are called pure aluminum sheets. Commonly used alloy codes for industrial pure aluminum sheets are 1050, 1060, 1070, and 1100. Among all aluminum sheet series, the pure aluminum sheet series contains the most aluminum. 1 series aluminum sheets are widely used in transformer aluminum strips, traffic signs, PCB aluminum sheet bases, curtain walls, metal casings, etc.

Pure aluminum sheet 1060

The moisture content of 1060 pure aluminum sheet is relatively high, usually the national standard is above 99.6%. The quality of 1060 industrial pure aluminum sheet is stable and the production process is relatively mature. Therefore, 1060 pure aluminum sheet is commonly used in the market where the aluminum content is relatively high, such as transformer aluminum strips, metal casings, etc.

Temper: O, H12, H14, H16, H18, H22, H24, H32, H34, H36, H38

Thickness: 0.1-50

Elongation: 3%-5%,

Tensile strength: 110MPa-136MPa

Aluminum content: ≥99.6%.

Pure aluminum sheet 1050

The aluminum content is more than 99.50%, which is one of the industrial pure aluminum. 1050 aluminum sheet has the characteristics of high plasticity, corrosion resistance, good electrical and thermal conductivity, but low strength. Widely used in lithium battery soft connections, tab materials, explosion-proof valves, heat sinks, signs, electronics, printing, curtain walls, stamping parts, etc.

Temper: O, H12, H14, H16, H18, H22, H24, H32, H34, H36, H38

Thickness: 0.1-50

Tensile strength: σb (MPa): 60~100

Elongation: δ/(%): ≥23

Elongation: 50mm/(%): ≥25.

Pure aluminum sheet 1070

The aluminum content of 1070 aluminum sheet reaches 99.7%. It has the characteristics of high plasticity, corrosion resistance, good electrical conductivity and thermal conductivity. Its advantages are often used to manufacture some structural parts with specific properties, such as protective nets for wires and cables, wire cores and aircraft. Ventilation system parts and trim.

Temper: O, H12, H14, H16, H18, H22, H24, H32, H34, H36, H38

Thickness: 0.1-50

Tensile strength σb (MPa) ): ≥75

Yield strength σ0.2 (MPa) ): ≥35.

Pure aluminum sheet 1100

1100 aluminum sheet is industrial pure aluminum, containing 99.00% aluminum. It has low density and good plasticity. It is usually used for components that require good forming performance, high corrosion resistance, and do not require high strength, such as sheet metal products and hollow hardware. , radiator, welding combination key, reflector, namesheet, etc.

Temper: O, H12, H14, H16, H18, H22, H24, H32, H34, H36, H38

Thickness: 0.1-50

Tensile strength σb (MPa): 110 ~ 136

Elongation δ10 (%): 3 ~ 5.

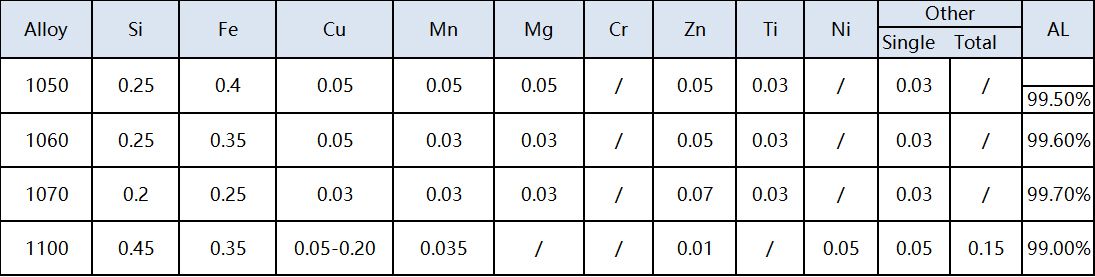

Chemical composition of 1 series aluminum sheet:

1 series pure aluminum sheet performance advantages:

1.Pure aluminum has a density close to 2700kg/m3, approximately 35% of the density of iron.

2.Through cold working, pure aluminum can be strengthened to more than twice its original strength. Additionally, alloying with elements such as magnesium, zinc, copper, manganese, silicon, lithium, and scandium, followed by heat treatment, can further increase its strength, making it comparable to high-quality alloy steel in terms of specific strength.

3.Aluminum can be cast using any casting method and has good plasticity, allowing it to be rolled into thin sheets and foils, drawn into tubes and fine wires, and extruded into various civil profiles. It can also be machined using most machine tools at maximum speeds for turning, milling, planing, and other mechanical processes.

4.The surface of aluminum and its alloys can easily form a dense, firm Al2O3 protective film, providing excellent resistance to atmospheric and water corrosion, as well as to most acids and organic corrosion. With the use of corrosion inhibitors and protective measures, the corrosion resistance of aluminum alloys can be further enhanced.

5.Unlike other materials, aluminum does not exhibit low-temperature brittleness; in fact, its strength and plasticity increase as the temperature decreases below zero degrees Celsius.

6.Aluminum has excellent electrical and thermal conductivity, second only to silver, copper, and gold.

7.Polished aluminum surfaces have a reflectivity of over 80% for white light, with higher purity resulting in higher reflectivity. Additionally, aluminum has good reflective properties for infrared, ultraviolet, electromagnetic waves, and thermal radiation.

8.Aluminum is non-magnetic and does not produce sparks upon impact. It also has sound absorption properties and is resistant to nuclear radiation. Finally, its aesthetically pleasing appearance adds to its appeal.

Contact Us