Difference between CC and DC aluminum circles

CC and DC aluminum circles are used to make cookware, such as cookware, pots, pans, pressure cookers, non-stick pans, etc. MC Aluminum can produce 1xxx, 3xxx, 5xxx and 8xxx series aluminum circles with thickness ranging from 0.5mm-6.0mm and diameter ranging from 100-1000mm.

Difference between CC VS DC aluminum discs:

1. Production method:

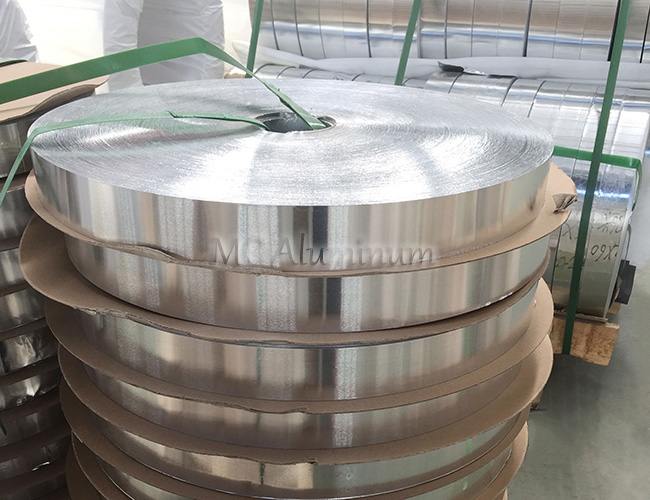

CC material (cast rolled billet) is a billet produced by continuous casting and rolling strip billets (generally 6-8mm thick) after cold rolling and annealing. CC aluminum circles are usually heavier because the density and thickness of aluminum are larger during the casting process.

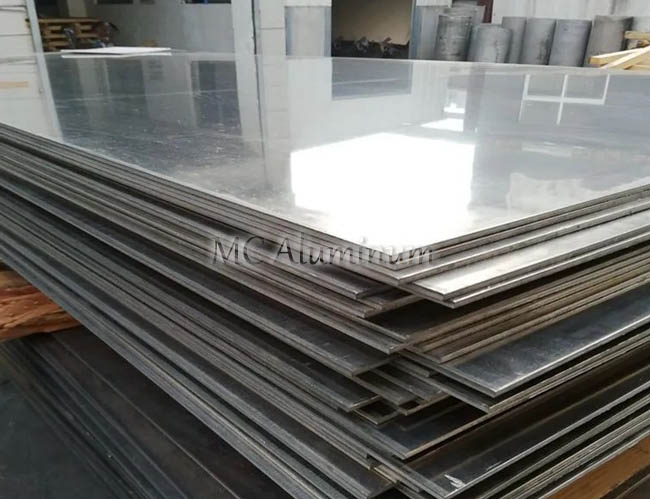

Hot rolled aluminum circles are billets produced by sawing, milling, billet heating, hot rolling, cold rolling and annealing of large ingots (thick flat ingots up to 600mm). Usually lighter, because the forging process makes aluminum denser, it can be made thinner but still maintain strength.

2. Performance characteristics and applications:

CC aluminum rings usually have good ductility and low cost, but poor deep drawing properties, suitable for mass production of ordinary cookware.

DC aluminum circles usually have better deep drawing performance and surface quality, suitable for subsequent processes such as stretching, deep drawing, spinning, oxidation, etc. DC aluminum circles are more expensive and suitable for application scenarios with higher requirements for material properties. Commonly used in the manufacture of high-end cookware, such as high-end non-stick pans, pressure cookers, etc.

In summary, there are obvious differences between cast aluminum circles and DC aluminum rings in production processes, performance characteristics and application fields. The choice of which aluminum ring depends on the specific application needs and performance requirements.

As a professional aluminum circle manufacturer, MC Aluminum provides common aluminum alloy circles such as AA1050, 1060, 1070, 1100, 3003, 5052, 5005 and 8011. The products are complete in models, stable in quality, and have bright and beautiful surfaces. They are in great demand in the market and are commonly used materials for kitchen utensils. They are exported overseas and are very popular with guaranteed after-sales service.

Contact Us