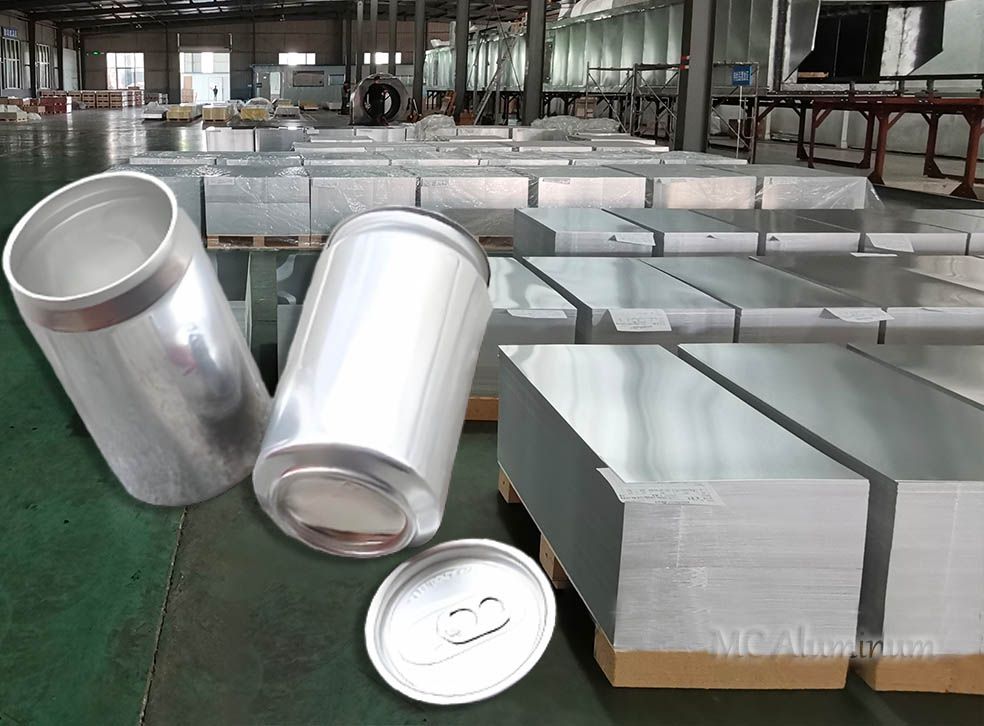

Food-Grade Aluminum Coil Strip for Beverage Can Lids & Ends

With the continuous improvement of consumers' awareness of food safety and environmental protection, food-grade aluminum coil strip has broad application prospects in the field of beverage packaging. Especially in packaging forms such as cans and aluminum bottle caps. Food-grade aluminum coil is an important material for beverage can lids and bottoms. The aluminum alloys used in can lids and bottoms belong to the 5 series and 3 series. Both are typical rust-proof aluminum series with significant food safety, recyclability, formability and sealing, and lightweight advantages.

Common aluminum alloys for can lids/bottoms:

Common aluminum alloys used for beverage can lids and bottoms include 5052, 3104, etc.

3104 aluminum alloy: It is a material commonly used for beverage can lids and bottoms, belonging to the aluminum-manganese alloy. It has good tensile strength and deep drawing performance, with an elongation of up to 20%. It can maintain good formability during stamping and other processing and is not easy to break. At the same time, due to the presence of manganese, the alloy has good corrosion resistance and can effectively resist the erosion of beverages and other contents to ensure product quality and safety. Its thickness range is generally 0.208-0.360mm, and the width range is 800-1730mm.

5052 aluminum alloy: has medium strength, good corrosion resistance and machinability. In the application of beverage can lids and can bottoms, it can provide better strength support, and can also meet the hygiene requirements of food contact. It is suitable for the production of easy-open lids and can bottoms that have certain requirements for strength and corrosion resistance.

Aluminum Coil Specifications:

| Alloy | 5052,3104 |

| Temper | H14, H19, H32 |

| Thickness | 0.18mm - 0.30mm |

| Width | 200mm - 1600mm |

| Length | 100mm - 1700mm |

| Surface Treatment | Mill finish, coated, or printed |

Features of Aluminum Coil for Beverage Can Lids and Bottom:

Corrosion resistance: Aluminum alloy has good corrosion resistance and can protect beverages from the influence of the external environment.

Plasticity: Aluminum alloy has good plasticity and is easy to process into various shapes of can lids and bottoms.

Lightweight: Aluminum alloy has low density, which can reduce packaging weight and transportation costs.

Recyclability: Aluminum alloy has high recyclability and meets environmental protection requirements.

Production process:

Aluminum coils are rolled, sheared, coated and other processes to finally make finished products that meet the requirements.

The coating usually includes an inner coating and an outer coating to improve corrosion resistance and aesthetics.

Quality requirements for aluminum coils:

1. Mechanical properties: good tensile strength, elongation and deep drawing performance to withstand the stress during the molding and use of can lids and can bottoms.

2. Surface quality: the surface is flat and smooth, without scratches, indentations and other defects.

3. Dimensional accuracy: small dimensional deviations such as thickness and width to ensure product consistency.

4. Hygienic performance: in line with food hygiene standards, no migration of harmful substances.

Contact Us