Why Aluminum Alloy 2024 Is the Ideal Material for Aircraft

Did You Know 2024 Aluminum Is Widely Used in Aircraft Structures?

Aluminum, like steel, is one of the most commonly used and readily available metals in commercial applications. It is utilized in everything from consumer products to critical aircraft components. Among aluminum alloys, 2024 aluminum stands out for its exceptional strength and fatigue resistance, making it a top material for aerospace structural reinforcements and supports.

Aluminum 2024

2024 aluminum alloy was first developed in 1931, and has since become a benchmark material in aircraft design due to its excellent mechanical properties. It is now widely used as a replacement for the older 2017-T4 alloy.

Part of the “hard aluminum” series, 2024 is mainly composed of aluminum, copper, magnesium, and manganese, offering superb fatigue strength and making it ideal for aerospace applications.

In heat-treated conditions, 2024 aluminum is annealed at 399–427°C (750–800°F) for about 2 hours, followed by slow cooling inside the furnace.

Between cold working stages, it may also be annealed at 343°C (650°F) for 2 hours, then air cooled.

Applications of 2024 Aluminum in Aerospace

2024 aluminum is widely used in aircraft structures, including:

Fuselage skin and frames

Wing skins and structural components

Rivets

Ribs and bulkheads

Other parts requiring high strength, stiffness, and fatigue performance

Key Properties of Aerospace-Grade 2024 Aluminum

1.Excellent Strength-to-Weight Ratio

Aircraft design prioritizes lightweight materials to improve fuel efficiency, range, and payload. With a density about one-third that of steel, 2024 aluminum offers high strength with reduced weight, helping reduce total aircraft mass.

2.Outstanding Fatigue Resistance

Aircraft endure repeated stress and strain cycles during flight. 2024’s fatigue resistance allows it to withstand prolonged, high-stress vibrations, ensuring long-term structural integrity and safety.

3.Heat Treatable for Enhanced Strength

2024 can be strengthened through solution heat treatment and artificial aging, showing exceptional mechanical performance in tempers like T3, T4, and T6—ideal for structurally demanding environments.

4.Stable Low-Temperature Performance

Aluminum’s strength increases at low temperatures, which is crucial for aircraft operating in high-altitude, cold environments.

5.Good Formability and Machinability

Aerospace-grade aluminum offers excellent ductility and formability, allowing for the creation of complex shapes with tight tolerances—key in the manufacturing of specialized aerospace parts, including for the International Space Station and spacecraft.

6.Recyclability

With growing focus on sustainability, aluminum’s recyclability is a key advantage, helping reduce the carbon footprint of aerospace projects.

Limitations of 2024 Aluminum – Not Without Drawbacks

Despite its many advantages, 2024 aluminum also has several limitations:

1.Poor Corrosion Resistance

It is prone to oxidation and corrosion, especially in humid or saline environments.

Solution: Surface cladding with pure aluminum (Alclad) or applying protective coatings.

2.Low Weldability

2024 is more difficult to weld than other alloys and is prone to cracking.

Solution: Riveting or bolted joints are typically used in aircraft structures instead of welding.

3.Lower High-Temperature Strength Compared to Titanium

In extreme heat or load conditions, 2024’s strength may not match that of titanium alloys.

Solution: Best suited for components where strength-to-weight ratio is critical but thermal resistance is not the primary concern.

Product Specifications

Chemical Composition of 2024 Aluminum (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Ohter:Total | Al |

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | remainder |

Mechanical Properties

| Property | Metric | Imperial |

Brinell Hardness | 120 | 120 |

| Knoop Hardness | 150 | 150 |

Rockwell Hardness A | 46.8 | 46.8 |

Rockwell Hardness B | 75 | 75 |

Vickers Hardness | 137 | 137 |

Ultimate Tensile Strength | 469 MPa | 68,000 psi |

Yield Strength | 324 MPa | 47,000 psi |

Elongation at Brea | 19–20% | 19–20% |

Elastic Modulus | 73.1 GPa | 10,600 ksi |

Bearing Strength (Ultimate) | 814 MPa | 118,000 psi |

Bearing Yield Strength | 441 MPa | 64,000 psi |

Poisson’s Ratio | 0.33 | 0.33 |

Fatigue Strength | 138 MPa | 20,000 psi |

Shear Modulus | 28 GPa | 4,060 ksi |

Shear Strength | 283 MPa | 41,000 psi |

Physical Properties

| Property | Metric | Imperial |

| Density | 2.77 g/cm³ | 0.10007 lb/in³ |

| Melting Point | 510°C | 950°F |

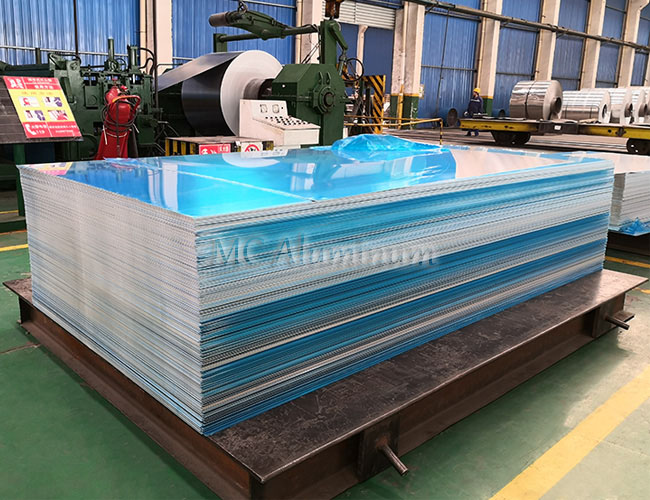

MC Aluminum is a leading aluminum plate manufacturer, supplying 2024, 7075, and other high-performance alloys for aerospace, aircraft, commercial, and industrial applications. Our products are exported to numerous countries worldwide, and we offer factory-direct pricing, samples, and global shipping.

Contact us today for custom sizes, material certifications, or bulk orders!

Contact Us