Is 7075 Aluminum Plate Suitable for Aircraft Parts?

7075 aluminum plate is an ultra-high-strength aluminum alloy belonging to the Al-Zn-Mg-Cu series. Since the late 1940s, it has been widely used in aircraft manufacturing — from the wing frameworks of fighter jets to the fuselage skins of commercial airplanes. Known as the “metal backbone above the skies,” 7075 aluminum continues to play a pivotal role in the aerospace industry due to its high strength and outstanding mechanical properties, especially under low temperatures below 150°C.

After solution heat treatment, 7075 aluminum exhibits good plasticity and excellent heat treatment strengthening effects. Although it has relatively poor weldability and a tendency toward stress corrosion cracking, these drawbacks can be mitigated through cladding or surface treatments. Double-aging treatments can further improve its resistance to stress corrosion cracking.

In annealed and freshly quenched conditions, 7075’s plasticity is slightly lower than 2A12 alloy but better than 7A04. Its static fatigue resistance, notch sensitivity, and stress corrosion performance — particularly in the T651 temper — are significantly better than 7A04, earning it the title of one of the most outstanding aluminum products. In terms of strength, it even surpasses mild steel.

In addition to its excellent mechanical properties, 7075 aluminum offers superb anodic response, making it a typical choice for aerospace and military-grade applications.

Is 7075 Aluminum Plate Suitable for Aircraft Parts?

Yes — 7075 aluminum plate is an ideal material for aircraft components. Its high strength (after heat treatment, it meets stringent standards) supports aerodynamic load-bearing demands for critical parts such as wing skins, ensuring long-term structural stability in flight. Its lightweight nature (density ~2.81g/cm³) significantly reduces aircraft mass and improves fuel efficiency, achieving over 30% weight reduction compared to steel.

Though it has basic corrosion resistance, surface treatments like anodizing (with a film thickness of 10–25μm) are recommended for high-humidity or salt-spray environments. In terms of processing, 7075 supports forging, extrusion, and precision machining (with tolerances as tight as ±0.05mm), making it suitable for complex structures like engine components.

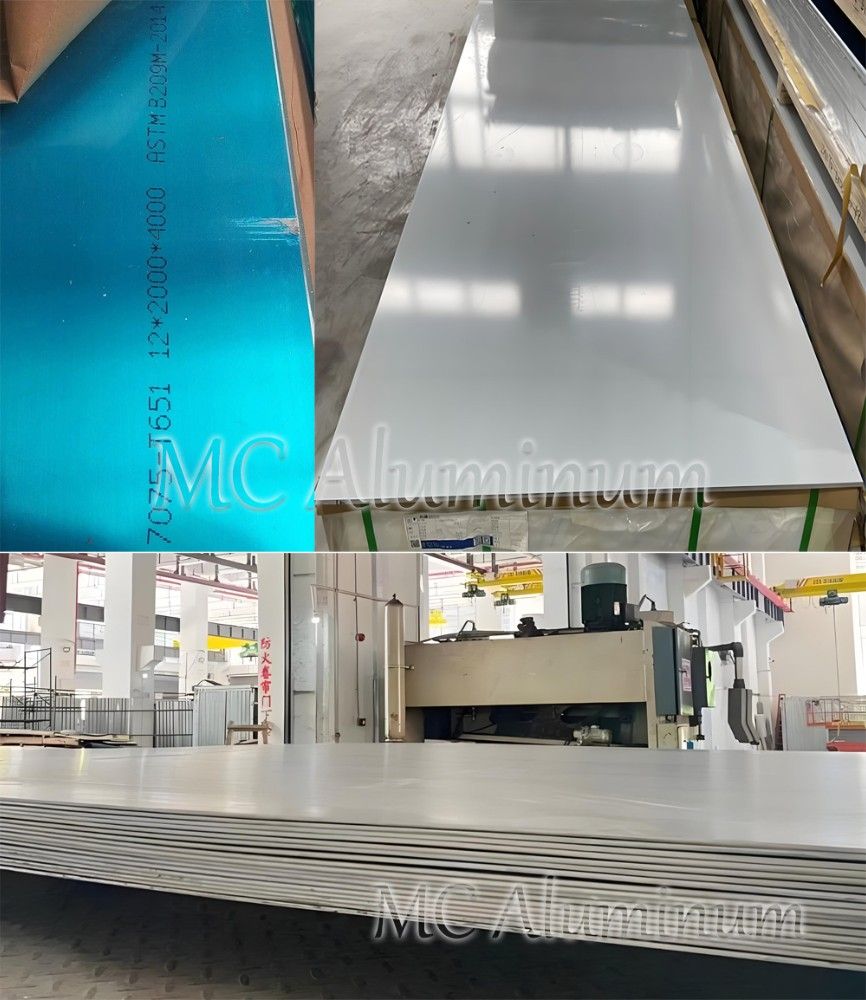

MC Aluminum is a professional aluminum plate manufacturer offering custom aerospace-grade 7075 plates in various heat-treated states such as T6 and T651. Our products feature flat surfaces, consistent quality, and large production capacity. We export to many countries and regions worldwide and offer samples. New and existing customers are welcome to visit our factory for inspection and consultation.

Contact Us