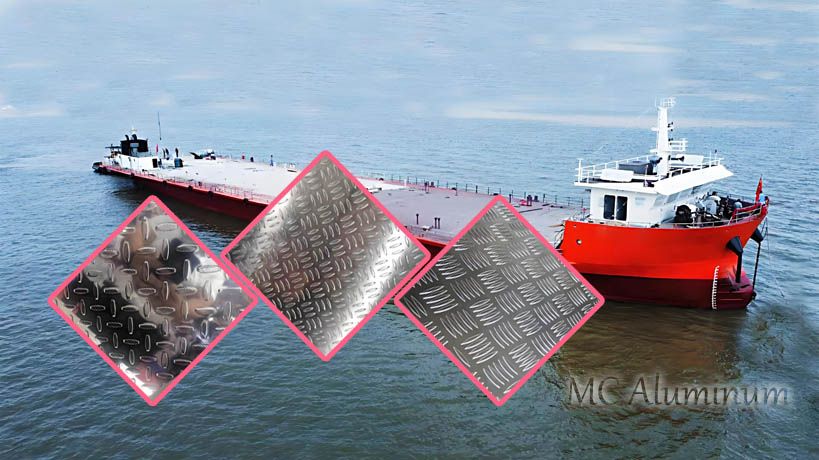

Marine aluminum plates for boat floor

In modern shipbuilding, the choice of flooring material is crucial. It must ensure sufficient load-bearing capacity while offering excellent anti-slip and corrosion resistance. Aluminum sheets for boat floors, known for their lightweight, high strength, and corrosion resistance, have become the preferred material in the marine industry.

Marine grade patterned aluminum plate often feature five-bar, three-bar, or diamond patterns, significantly enhancing friction and reducing the risk of accidental slips, ensuring safety for both passengers and crew. These aluminum sheets are primarily made from 5052, 5083, and 5754 high-corrosion-resistant aluminum alloys. Among them, 5083 marine aluminum sheets are ideal for large ship decks and heavy-duty areas due to their superior strength and corrosion resistance, while 5052 and 5754 aluminum sheets are widely used in passenger ferries and speedboats.

To guarantee product quality, aluminum sheets for boat building must meet the strict standards of CCS (China Classification Society), DNV (Det Norske Veritas), ABS (American Bureau of Shipping), and other international classification societies, ensuring stable performance in various marine environments.

Specifications of Marine-Grade Aluminum Sheets

| Alloy | 5052, 5083, 5754, 6061,etc |

| Temper | H32, H111, H116, T6 |

| Thickness | 3mm - 10mm (commonly used) |

| Width | 1000mm - 2000mm |

| Length | 2000mm - 16000mm (customizable) |

| Surface Type | Five-bar, three-bar, diamond pattern, anti-slip texture |

| Density | ~2.7g/cm³ (about one-third of steel) |

| Tensile Strength | 275 - 400 MPa (varies by alloy type) |

| Yield Strength | 125 - 270 MPa |

| Elongation | 10% - 16% |

| Certification Standards | CCS, DNV, ABS, BV, LR (International Classification Societies) |

Advantages of Marine-Grade Aluminum Sheets for Boat Flooring

1. Lightweight Design

Aluminum alloys have a density about two-thirds lower than steel, reducing the overall weight of the vessel. This improves fuel efficiency, lowers emissions, and makes ships more environmentally friendly and energy-efficient.

2. Excellent Corrosion Resistance

Made from 5052, 5083, and 5754 corrosion-resistant aluminum alloys, these sheets can withstand saltwater and humid environments for long periods without frequent replacements, effectively lowering maintenance costs.

3. High Strength & Durability

Both 5083 and 6061 aluminum alloys offer high tensile and yield strength, ensuring they can withstand heavy loads on ship decks, walkways, and structural areas. Additionally, they provide great impact and fatigue resistance for long-term use.

4. Anti-Slip Design for Enhanced Safety

The surface features five-bar, three-bar, or diamond patterns, significantly improving grip and reducing the risk of slipping in wet and marine environments, thus ensuring passenger and crew safety.

5. Easy Processing & Excellent Weldability

Aluminum sheets can be cut, bent, welded, and drilled, making them highly adaptable to different ship floor structures. Their superior weldability enhances the efficiency of ship manufacturing and assembly.

Applications

1.Ship Decks: Suitable for yachts, cargo ships, fishing vessels, and passenger ferries as the main deck or walkway flooring.

2.Cabin Flooring: Ideal for moisture-prone ship interiors, preventing corrosion and slip-related accidents.

3.Yacht Interiors & Exterior Platforms: Provides an aesthetic yet corrosion-resistant flooring solution.

4.Offshore Drilling Platforms: Offers stable and durable flooring in harsh marine environments.

As an aluminum plate manufacturer, MC Aluminum can accept orders for 1-2000 tons of marine aluminum plates, customized on demand, and delivered within 7-35 days. The product quality is stable, exported globally, and the price is affordable. Samples are provided, so you can purchase with confidence!

Contact Us