Marine aluminum reinforcement plate

Marine aluminum reinforcement plate is composed of thin plate (the so-called skin) and reinforcement ribs, and the strength, rigidity and fatigue resistance of the plate are improved by adding reinforcement ribs. Nowadays, FSW welding of reinforcement plates is becoming more and more popular in high-tech industries. Friction stir welding technology can produce lighter and stronger reinforcement plates. Reinforced aluminum plates have a wide range of applications in ship design, especially in hulls, decks and internal structures, and are widely adopted for their lightweight, high strength and corrosion resistance.

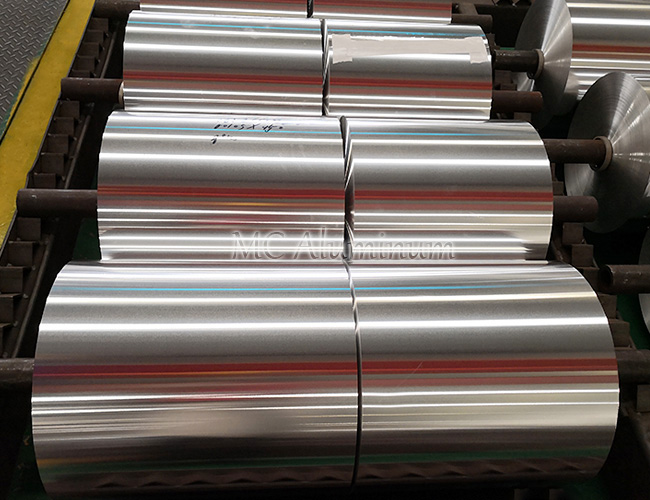

MC Aluminum has an internationally first-class friction stir welding (FSW) rib wall plate production line, specializing in the production of marine aluminum alloy reinforced plates, which are widely used in products such as rescue boats, missile boats, frigates, destroyers and civil ships such as fishery ships, marine surveillance ships, and luxury yachts.

Why is friction stir welding used for reinforcement plates?

1. Simple process, providing completely non-porous, leak-free, dense and high-strength joints

2. Minimal thermal impact on materials. Small thermal stress on cargo and flat surfaces

3. Good mechanical properties. Few variables in the production process, easy to control, allowing tight tolerances

4. Excellent repeatability, very suitable for automation

Specifications of marine aluminum reinforcement plates:

| Alloy | 6082, marine aluminum alloy |

| Temper | T6 |

| Welding method | stir friction welding |

| Width | ≥2100mm |

| Length | 100-16000mm |

| Maximum width of a single profile | 600mm |

| Maximum length of a single profile | 16200mm |

Marine grade ribbed aluminum plate

1. Good anti-rust and anti-corrosion performance.

2. Easy to process.

3. Good welding performance.

4. Improve the performance of hull structure.

5. Shorten the construction period of pure aluminum alloy hull structure.

6. Lightweight, high strength and high stiffness.

7. Reduce the pollution of welding operations to the environment and promote environmental protection.

Marine aluminum reinforcement plates are widely used in rescue boats, missile boats, frigates, destroyers, fishing boats, yachts, etc., including ship construction and maintenance, including but not limited to:

1. Hull structure: used to reinforce the hull structure, improve the overall strength and stability of the hull, and ensure the safe navigation of the ship in severe sea conditions.

2. Deck and cabin: used to reinforce the deck and cabin structure to prevent deformation and damage caused by heavy loads or impacts.

3. Fuel tank and water tank: as a reinforcement material for fuel tanks and water tanks, improve the load-bearing capacity and safety of fuel tanks and water tanks.

4. Other marine equipment: such as reinforcement materials for marine ladders, railings, gangways and other equipment to ensure the stability and safety of these equipment during use.

Contact Us