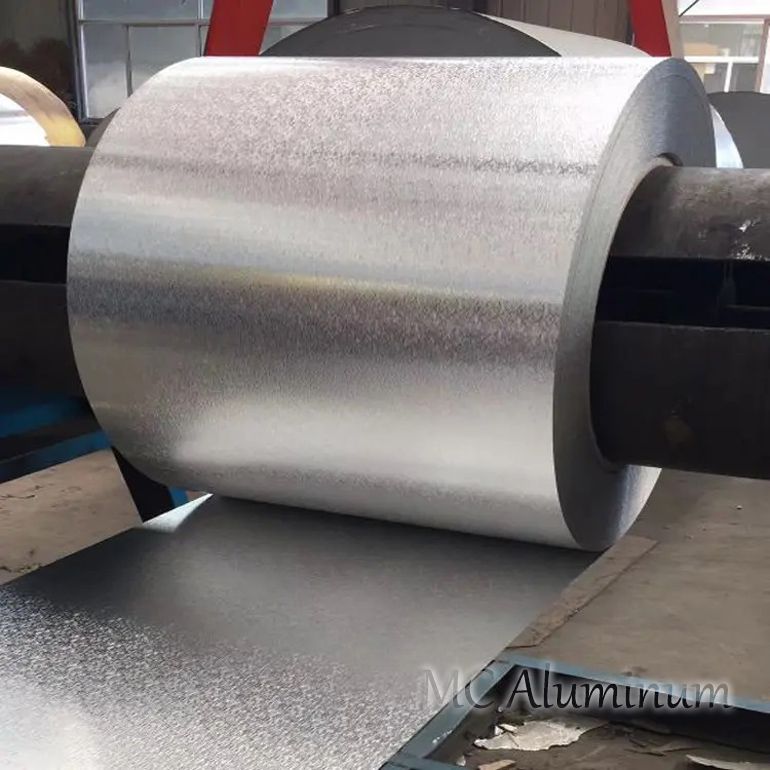

Orange peel embossed aluminum coil

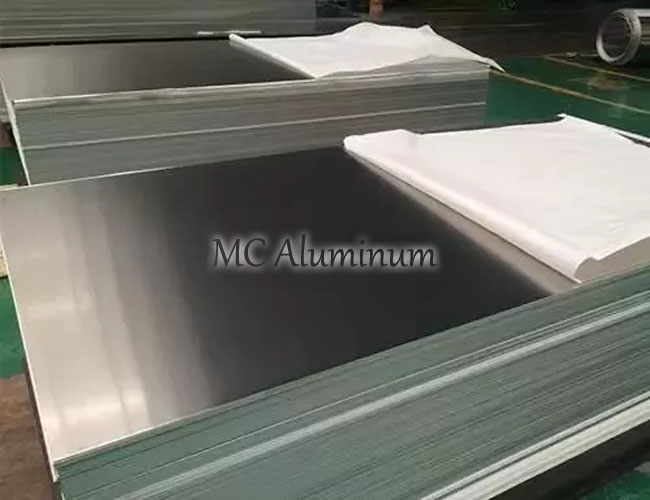

Orange peel embossed aluminum coil is a product that is pressed and formed by embossing equipment. The pattern is similar to orange peel. After embossing, the thickness and strength of the aluminum plate can be enhanced. Therefore, it is called orange peel aluminum plate in the industry. MC Aluminum produces various types of orange peel aluminum coils, orange peel aluminum plates, etc.

The orange peel pattern can be anodized. After oxidation, a dense protective film of aluminum trioxide is formed on the surface, which is acid-resistant and corrosion-resistant, with lasting luster and beautiful patterns. It has stable anti-corrosion performance, strong adhesion and does not fall off, is impact-resistant, does not produce toxic gases, and is safe and environmentally friendly. The surface of the product is clean and shiny. Oxidation can remove residual oil stains on the surface of aluminum plates and manual handling fingerprints. It has strong adaptability and wide range of uses.

Orange peel aluminum coil products are widely used in aerospace, molds, instrumentation, chemical industry, construction, packaging, anti-corrosion insulation, air conditioning, solar energy, refrigerators and other industries. At present, in the refrigeration industry, 3003 series anti-rust aluminum coils are usually used as the base material, while orange peel aluminum coils for pipe insulation and packaging are usually 1060 series.

The thickness of orange peel aluminum coils is 0.2mm, 0.3mm, 0.35mm, 0.4mm, 0.45mm, 0.5mm aluminum skin, 0.6mm aluminum skin, 0.7mm, 0.8mm, 1mm, 1.2mm, 1.5mm, 2mm, 2.5mm, 3 mm, etc., specifications can be customized, and can be cut to flat lengths with fast delivery time.

Contact Us