Thin aluminum strips for hollow glass spacers

Thin aluminum strip are used to make aluminum alloy frames in hollow glass, hold desiccants and fix the distance between glass sheets. Compared with other frame materials such as rubber strips, aluminum alloys are not easy to oxidize, have good corrosion resistance, are light in weight, do not deform, have a bright surface, and do not react with desiccants, so they have good anti-aging and decorative properties. At present, aluminum spacers are made by rolling aluminum strips and high-frequency welding;

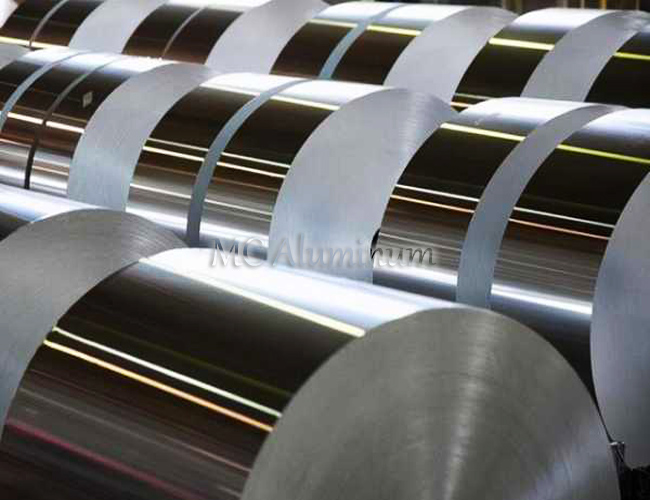

Because 3003 alloy has the characteristics of high strength, good resistance, excellent welding and corrosion resistance, it has become the preferred alloy variety for hollow glass aluminum spacers for rolling and high-frequency welding. The main specifications and alloy states of aluminum alloy strips for spacers are: 3003-H26 with 0.34mm or 0.35mm and 3003-H38 with 0.27mm. The former requires the material tensile strength to be controlled at 190~210MPa and the elongation to be more than 10%; the latter requires the tensile strength to be controlled at 230~250MPa and the elongation to be more than 5%.

Advantages of hollow aluminum strips for glass spacers:

1. High strength

2. Good toughness

3. Anti-corrosion

4. No deformation

5. High brightness

6. Can meet the requirements of continuous operation of the production line.

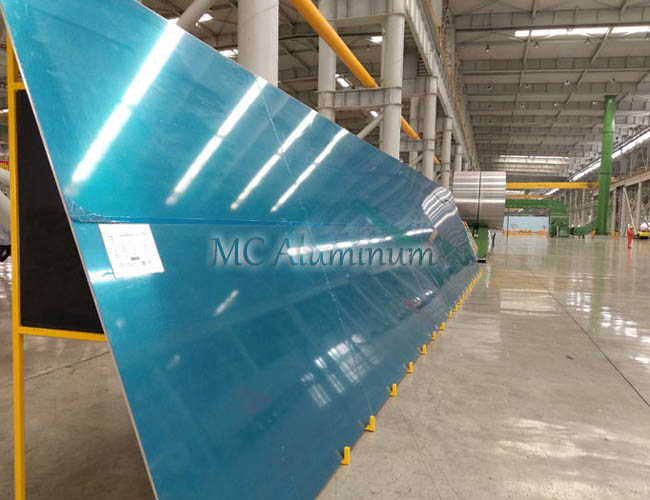

MC Aluminum provides aluminum strips, thin aluminum strip, glass strip aluminum strips, and hollow glass aluminum strips with complete models, stable quality, smooth surface, no bumps, uniform and neat pores, meeting customer needs, exported to many overseas countries, preferential prices, and after-sales guarantee. You can order with confidence.

Contact Us