5456 H116 Aluminum Alloy Plate for Shipbuilding

5456 marine aluminum plate is an aluminum-magnesium anti-corrosion alloy with strength comparable to 5A03. It is typically used in structural applications and can achieve higher strength through cold working. However, prolonged exposure to temperatures ranging from 65°C to 200°C may lead to exfoliation and corrosion. Our common grades include 5456-H116, H111, and H321 aluminum plates.

Applications of 5456 Aluminum Alloy

5456 aluminum alloy is mainly used in shipbuilding and other engineering applications where high strength and excellent welding characteristics are required. Its tensile strength is higher than that of other marine alloys such as 5083 or 5086. It also has excellent corrosion resistance in seawater environments, along with good workability and weldability.

What Is 5456 H116 Aluminum Alloy?

5456 is a member of the 5xxx series aluminum-magnesium alloys, containing a relatively high percentage of magnesium (Mg), which gives it excellent strength and corrosion resistance. The H116 temper is a specially processed condition designed for marine applications, featuring:

Stress-relieved processing to improve corrosion resistance

Excellent weldability and formability

Superior resistance to exfoliation and pitting corrosion

Specifications of 5456 H116 Aluminum Alloy Plate

| Item | Specification |

| Product Name | 5456 Aluminum Plate |

| Alloy | 5456 |

| Temper | H111, H116, H321, T651, T6 |

| Thickness | 3.0–50 mm |

| Width | 100–2300 mm |

| Length | 300–10000 mm |

| Standards | AISI, ASTM, BS, DIN, GB, JIS |

| Tensile Strength | 350–800 MPa |

| Yield Strength | 250–600 MPa |

| Processing | DC or CC |

| Applications | Pressure vessels, tanks, truck parts, marine equipment |

| Highlight Features | Aluminum decking plate, aluminum metal sheet |

Physical Properties of 5456 H116 Marine Aluminum Plate

| Temper | Thickness (mm) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| H116 | 1.5–3.0 | 330–415 | ≥240 | ≥10 |

| 3.1-6.0 | ≥12 | |||

| 6.1–12.5 | ≥14 | |||

| 12.6-50 | ≥16 |

Chemical Composition of 5456 Aluminum Alloy (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 5454 | 0.4 | 0.4 | 0.1 | 0.4-10. | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | 0.05 | 0.15 | Remainder |

Key Performance Features of 5456 H116 Marine Grade Aluminum Plate

1.Corrosion Resistance

The high magnesium content of 5-series aluminum alloys offers excellent seawater corrosion resistance. The H116 temper further enhances resistance by reducing continuous precipitation of β phase (Mg₂Al₃) along grain boundaries, which minimizes the risk of intergranular and exfoliation corrosion.

2.Weldability and Workability

The alloy is well-suited for MIG/TIG welding, commonly using 5356 aluminum welding wire to improve crack resistance. It also has good formability, making it suitable for extrusion and welding in complex ship structures.

3.High Strength

Despite aluminum being lightweight, 5456 offers high strength, meeting the structural rigidity demands of speedboats, military vessels, and offshore platforms.

4.Lightweight Design Advantage

Aluminum has only about one-third the density of steel. Using 5456 aluminum plates significantly reduces hull weight, increases speed, and improves fuel efficiency—making it an essential material for modern eco-friendly marine vessels.

Wide Applications of 5456 H116 Aluminum Plates in Shipbuilding

Hull Structures: Widely used in bottom plates, hulls, and decks that require both high strength and corrosion resistance.

Superstructures: Especially suitable for the superstructures of warships and high-speed vessels, such as hydrofoils and hovercraft, where reducing weight is essential.

Fuel Tanks and Pressure Vessels: Frequently used for marine fuel tanks and pressure containers due to its high strength and excellent corrosion resistance.

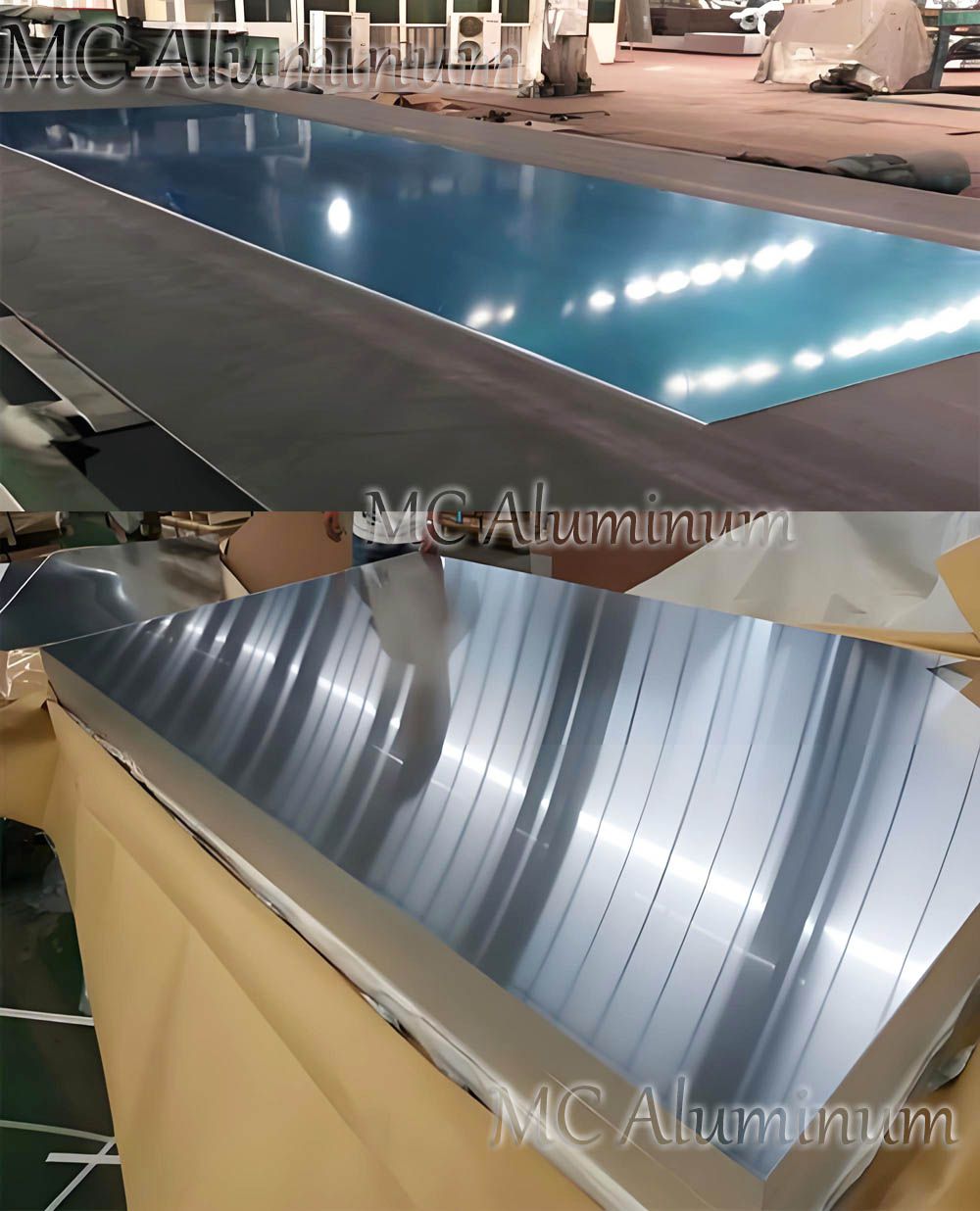

MC Aluminum is a professional aluminum plate manufacturer offering marine-grade certified products in tempers such as H321, H116, H111, H112, and T6, covering alloys like 5086, 5083, 5456, 6061, 6082, and more. We provide consistent product quality, complete specifications, fast global delivery, free samples, factory-direct pricing, and attractive discounts.

Contact Us