Tropical blister aluminum substrate

Among the current packaging substrates, the barrier properties of aluminum foil are very good. With this advantage, aluminum foil is widely used in various packaging materials. In the field of pharmaceutical packaging, aluminum foil can be used in PTP aluminum foil packaging, tropical blister packaging, cold stamping packaging and pharmaceutical bottle caps, and the requirements for aluminum foil materials are relatively high.

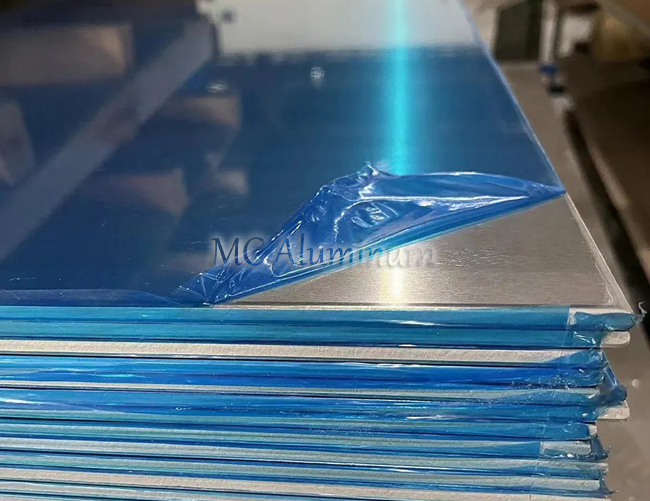

Tropical blister aluminum is mainly composed of aluminum foil layer and other composite materials, which is a relatively high-end pharmaceutical packaging. As a substrate, the aluminum foil layer has excellent moisture-proof, anti-oxidation, light-proof and gas-proof properties. In order to enhance its performance and adaptability, the aluminum foil layer is usually coated or compounded with other materials, such as polyamide layer, polyester layer, heat-sealing coating, etc. These composite materials can further improve the barrier properties, heat-sealing properties and mechanical strength of tropical blister aluminum.

Tropical blister packaging mainly uses 8021 aluminum foil and 8079 aluminum foil. High-quality medicinal aluminum foil has higher requirements for quality indicators such as toxic and harmful element content, plate shape, thickness, surface quality (including color difference, stripes, bright lines, bright spots, etc.), pinholes, heat resistance, and heat sealing strength.

Specifications:

| Structure | OPA/AL/DVC |

| Alloy | 8011, 8021, 8079 |

| Temper | O, H14, H16, H18, etc |

| Thickness | 0.016-0.05mm |

| Width | 10-600mm |

| Length | C |

| ID | 76/152mm |

| OD | 280mm |

| Color | gold, silver, customizable |

| Application | used for aluminum-plastic blister packaging such as capsules and tablets. |

Features:

1. Excellent barrier properties: effectively resist water vapor, oxygen and light, and extend the shelf life of products.

2. Good heat sealing performance: apply heat sealing coating to ensure packaging sealing and prevent leakage.

3. High strength and toughness: Aluminum foil and composite materials provide high strength and toughness to protect products from damage.

4. Environmental protection and sustainability: Recyclable, energy consumption and emissions in the production process are gradually reduced.

5. Easy to print and process: The outer layer of aluminum foil is suitable for printing and clearly displays the identification information.

MC Aluminum is a manufacturer of aluminum foil raw materials for tropical blister packaging, specializing in the production of 8021 aluminum foil and 8079 aluminum foil, etc., with high cup convexity, high heat sealing strength, no pinholes, good sealing and other advantages. It is a supplier of aluminum foil raw materials for various pharmaceutical packaging companies at home and abroad. The company has a complete range of product models and stable quality. It can accept orders of 1-200 tons and export to many countries overseas.

Contact Us