What aluminum sheet is used for shipbuilding?

Application of aluminum sheet on ship hull:

The form of ship hull structure of ships and ships can be divided into three types: horizontal skeleton type, longitudinal skeleton type and mixed skeleton type. Aluminum alloy small fishing boats, river boats and large boats are often used for the head and tail end structures of transverse frame structures. The aluminum alloy materials used on the hull are mainly plates, profiles and wide integral extruded aluminum profiles.

The following are some common brands of marine aluminum plates:

1.5083 marine aluminum plate

5083 aluminum plate is a high-magnesium alloy aluminum plate, the main alloying element is magnesium, which has good corrosion resistance and weldability, as well as medium strength. Excellent corrosion resistance enables 5083 alloy to be widely used in marine applications such as ships, as well as automobiles, aircraft welding parts, subway light rails, pressure vessels that require strict fire protection (such as liquid tankers, refrigerated vehicles, refrigerated containers), refrigeration units, TV towers, Drilling equipment, transportation equipment, missile parts, armor, etc. Good strength, corrosion resistance and machinability in non-heat treatable alloys. After anodizing, the surface is beautiful, and it can be processed into optical mechanical parts, ship parts and wire clips.

5083 aluminum plate performance

| Alloy | 5083 |

| Temper | O,12,H14, H16,H18,H19, H22,H24,H26, H28,H32,H34 H36,H38,H111, H112,H114,H 116,H321 |

| Thickness | 0.15~600mm |

| Width | 20~2650mm |

| Length | 500~16000mm |

| Application | Ships, automobiles, aircraft welding parts, subway light rail, etc. |

Advantages of 5083 aluminum plate

(1).5083 alloy aluminum plate has low density, high strength, corrosion resistance, durability, and plays an important role in the lightweight of transportation.

(2).The surface of 5083 aluminum plate has no oil spots, no waves, no scratches, no roll marks, neatly trimmed edges, and no burrs.

2.5052 marine aluminum plate

552 aluminum plate is AL-Mg alloy gold aluminum plate, which is mainly used in yacht hull and hull parts. It is a kind of rust-proof aluminum which is widely used in Z. This alloy has high strength, especially anti-fatigue strength: 5052 aluminum plate is commonly used in sheet metal parts of traffic vehicles and ships, instruments, street lamp brackets and rivets, hardware products, electrical appliance housings, etc.

5052 aluminum plate performance

| Alloy | 5052 |

| Temper | O,H12,H14,H16,H18,H19,H22,H24,H26,H28,H32,H34,H36,H38,H111,H112,H114,H 116,H321 |

| Thickness | 0.15~600mm |

| Width | 20~2600mm |

| Length | 500~16000mm |

| Application | Oxidizing material, trolley case, 5052 fuel tank material, LCD backplane, tank material, door plate material, etc. |

Advantages of 5052 aluminum plate

(1).With high plasticity, corrosion resistance, suitable for use in marine environment.

(2).There is no peeling, bubbles, rough surface and local mechanical damage on the surface of the aluminum plate, and no cracks, corrosion spots and traces of nitrate on the surface of the aluminum plate.

3.6061 Marine aluminum plate

The main alloying elements in 6061 alloy are magnesium and silicon, which have medium strength, good corrosion resistance, weldability and good oxidation effect. It is widely used in various industrial structural parts that require certain strength and high antibacterial corrosion resistance.

6061 aluminum plate performance

| Alloy | 6061 |

| Temper | O, T4, T6, T651 |

| Thickness | 0.3~600mm |

| Width | 500~2600mm |

| Length | 500~16000mm |

| Application | Mobile phone card slot, mobile phone case, mold, automobile, precision machining, etc. |

Advantages of 6061 aluminum plate

Excellent processing performance, good corrosion resistance, high toughness and no deformation after processing, easy to coat, good oxidation effect, excellent weldability, good cold workability.

4.7075 Marine aluminum plate

775 marine aluminum plate is a kind of super-hard aluminum, and its main alloy element contains zinc. 775 alloy aluminum plate has the characteristics of high strength and hardness, far superior to steel. Typically used in golf balls, molds, and other applications, it has good corrosion resistance and oxidation resistance, as well as good processability, wear resistance, and usability. It has high strength below 150℃ and especially good low-temperature strength.

7075 aluminum plate performance

| Alloy | 7075 |

| Temper | O,T6,T651 |

| Thickness | 0.2~300mm |

| Width | <1500mm |

| Length | <8000mm |

| Application | Aircraft upper and lower wing panels, stringers, bulkheads, etc. |

Advantages of 7075 aluminum plate

(1).High Strength Heat Treatable Alloys

(2).Good mechanical properties, easy processing, good wear resistance, corrosion resistance, good oxidation resistance.

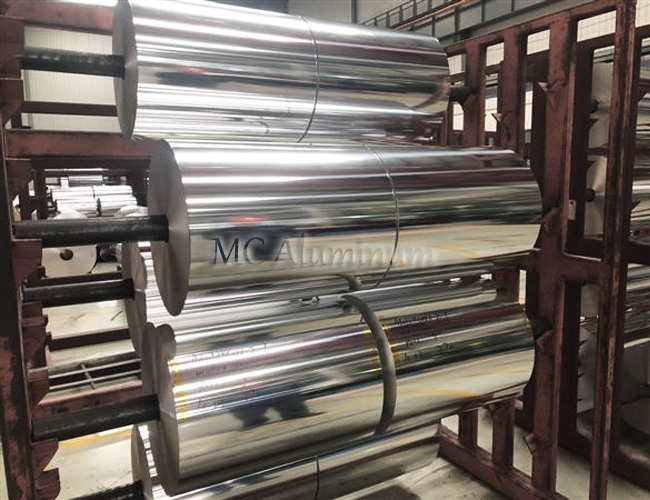

MC Aluminum specializes in the production of various specifications of aluminum sheets, aluminum coils, aluminum circles and other aluminum products. MC Aluminum can provide you with the latest product quotations. Looking forward to your consultation!

Contact Us