What is the difference between aluminum and marine-grade aluminum?

Aluminum is a high-quality material with exceptional corrosion resistance. It is highly valued for its ease of processing and high fatigue strength. However, in the harsh marine environment, salt and moisture rapidly corrode ordinary aluminum alloys, rendering them incapable of meeting the requirements of long-term service. To address this challenge, alloying (the addition of specific alloying elements such as magnesium) significantly enhances aluminum's properties, leading to the development of marine-grade aluminum.

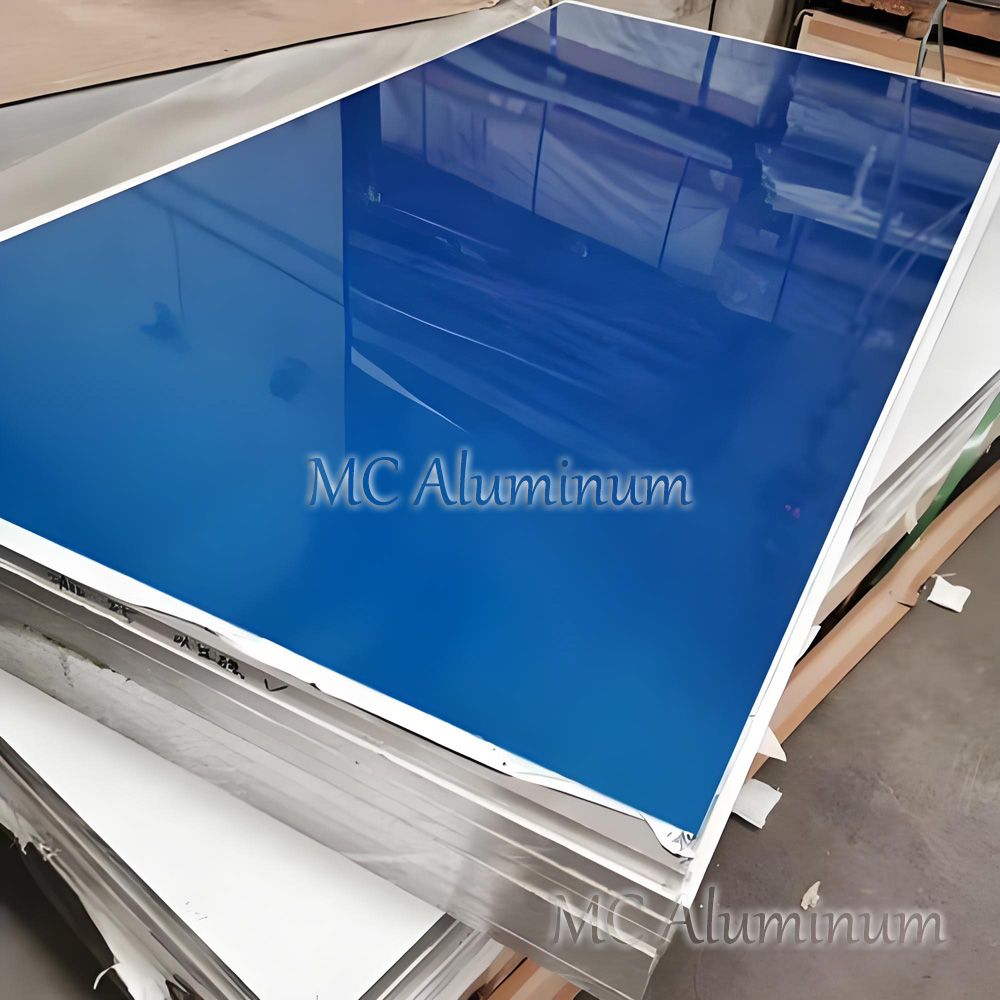

Marine-grade aluminum comes in a variety of alloys. MC Aluminum offers both 5-series and 6-series marine-grade aluminum alloys, each with unique properties due to the alloying elements within the base material.

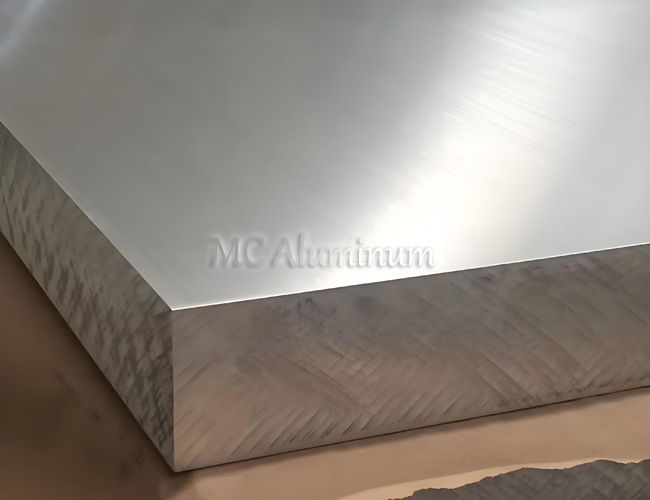

Different marine-grade aluminum alloys are available in a variety of stock formats, including plate, sheet, coil, tubing, extrusions, and bar.

Performance Characteristics of Marine-Grade Aluminum

Corrosion Resistance: Marine environments (saltwater and salt spray) are extremely corrosive. Marine aluminum must possess exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking. Galvanic corrosion (when aluminum is joined to metals such as steel and copper) must also be considered, which is critical in multi-material marine applications.

Weldability: Welding is extensively used in shipbuilding. Marine aluminum must exhibit excellent weldability, and the degradation of mechanical properties and corrosion resistance in the joint area after welding must be within acceptable limits.

Low-temperature toughness: Ships sailing in cold waters must not become brittle. Marine aluminum must maintain good impact toughness even at low temperatures.

Fatigue performance: Ships are subjected to long-term cyclical loads from waves, and the material must exhibit excellent fatigue resistance to ensure long-term safety.

The most common aluminum alloys include

5XXX aluminum-magnesium alloys (5083, 5052, 5059, 5383, 5456, 5754)

1.5083 aluminum alloy (H116/H321/O temper)

Features: High strength, strong corrosion resistance, good weldability, and cannot be heat-treated for strengthening.

Applications: Hull main plates, bulkhead plates, decks, bottom plates, etc., making it the most widely used alloy in marine aluminum.

Typical parameters: Tensile strength ≥ 270 MPa, elongation ≥ 12%.

2. 5086 aluminum alloy (H116/H321)

Features: Better corrosion resistance than 5083, maintains good strength after welding, and offers excellent resistance to seawater corrosion.

Applications: Hull hulls, decks, and ship armor.

Typical parameters: Tensile strength ≥ 260 MPa, good low-temperature toughness.

3. 5456 Aluminum Alloy (H116 / H321)

Features: Higher magnesium content than 5083 and 5086, resulting in higher strength, but intergranular corrosion may occur with long-term service.

Applications: Medium-to-high-strength parts of ships, such as ribs and frame structures.

Typical Parameters: Tensile strength ≥ 310 MPa.

4. 5754 Aluminum Alloy

Features: Medium strength, good corrosion resistance, and excellent weldability.

Applications: Hull interiors, oil tanks, and liquid storage tanks.

Al-Mg-Si Alloy - 6XXX (6061)

1.6061 Aluminum Alloy (T6 / T651)

Features: Heat-treatable and hardenable, with high strength, good toughness, and excellent corrosion resistance.

Applications: Hull structural components, deck frames, marine ladders, and portholes.

Typical Parameters: Tensile strength ≥ 290 MPa, yield strength ≥ 240 MPa.

2. 6082 Aluminum Alloy (T6 / T651)

Features: Higher strength than 6061, with improved toughness and weldability, widely used in European shipbuilding.

Applications: Ship ribs, deck reinforcements, and load-bearing structures.

Typical parameters: Tensile strength ≥ 310 MPa.

Differences between Aluminum and Marine Aluminum

1. Composition

Ordinary aluminum (such as the 1xxx series, such as 1050, 1060, and 1100) is nearly pure aluminum, with low alloying element content and low strength.

Marine aluminum is primarily concentrated in the 5xxx series (Al-Mg) and 6xxx series (Al-Mg-Si). Alloying elements impart higher strength and enhanced corrosion resistance.

2. Corrosion Resistance

Ordinary aluminum forms an oxide film in air but is easily corroded by salt spray and seawater.

Marine aluminum undergoes a special formulation and heat treatment, resulting in excellent seawater corrosion resistance and long-term service life.

3. Different Mechanical Properties

Ordinary aluminum has good ductility but low tensile strength and yield strength.

Marine-grade aluminum offers a balance of strength and plasticity, capable of withstanding the dynamic stresses and impact loads generated by a ship's hull in wind and waves.

4. Different Applications

Ordinary aluminum: Used in daily necessities, signage, lightweight packaging, and other materials.

Marine-grade aluminum: Used in load-bearing areas and those exposed to seawater, such as hull structures, decks, bulkheads, and ribs.

MC Aluminum, a professional aluminum fabricator, produces aluminum sheets, coils, foils, discs, profiles, and ribbed plates in aluminum alloy series 1-8. These products offer a wide range of applications and consistent quality, and are exported to numerous countries and regions with competitive prices and fast delivery.

Contact Us